Friction welding control and quality evaluation method based on weld temperature and spatter detection

A quality evaluation and friction welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of inability to re-weld, prolong welding time, waste production costs, etc., and reduce the number of re-welding and scrapped products. , Guarantee welding quality, evaluate the effect of comprehensive information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

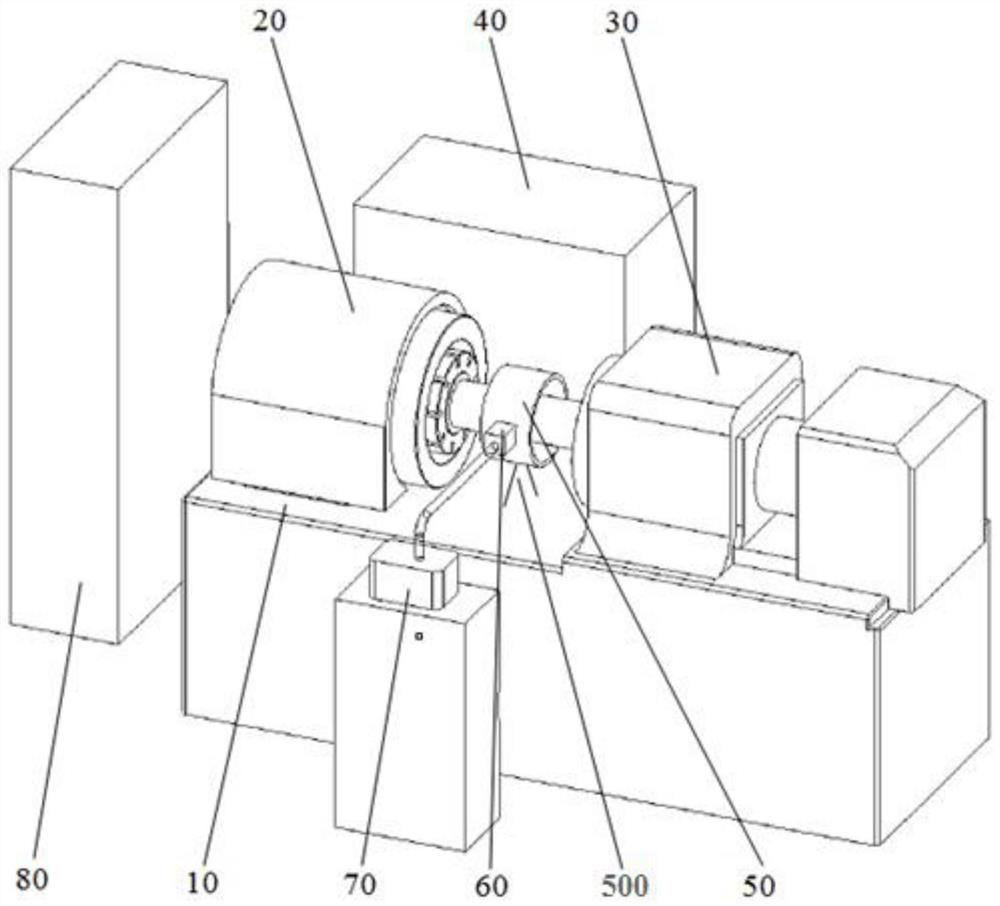

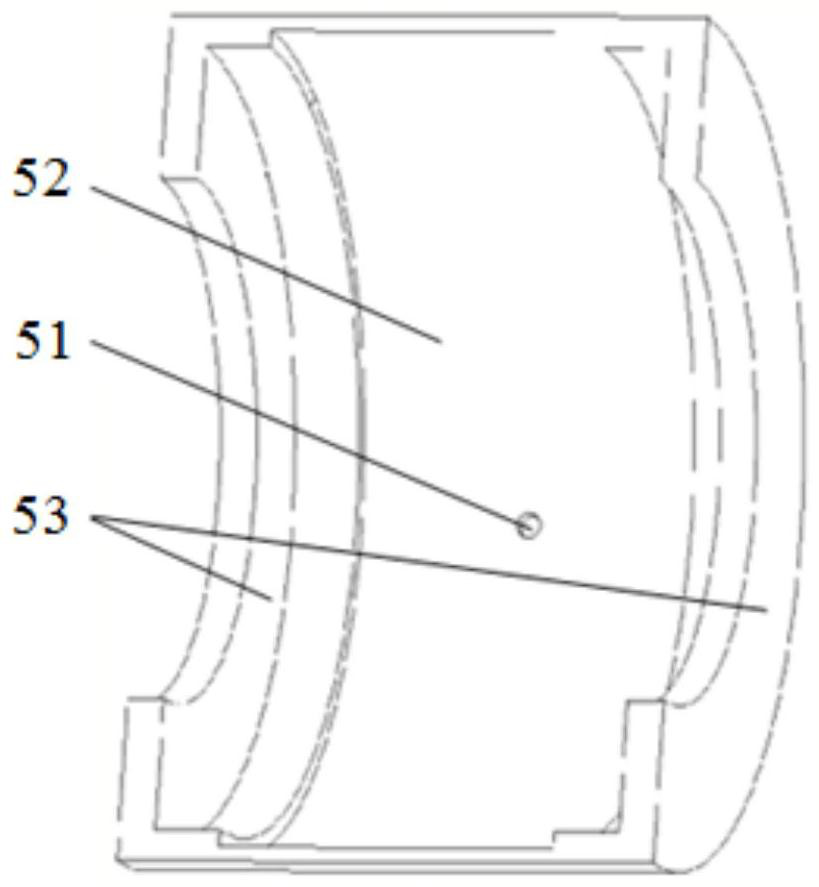

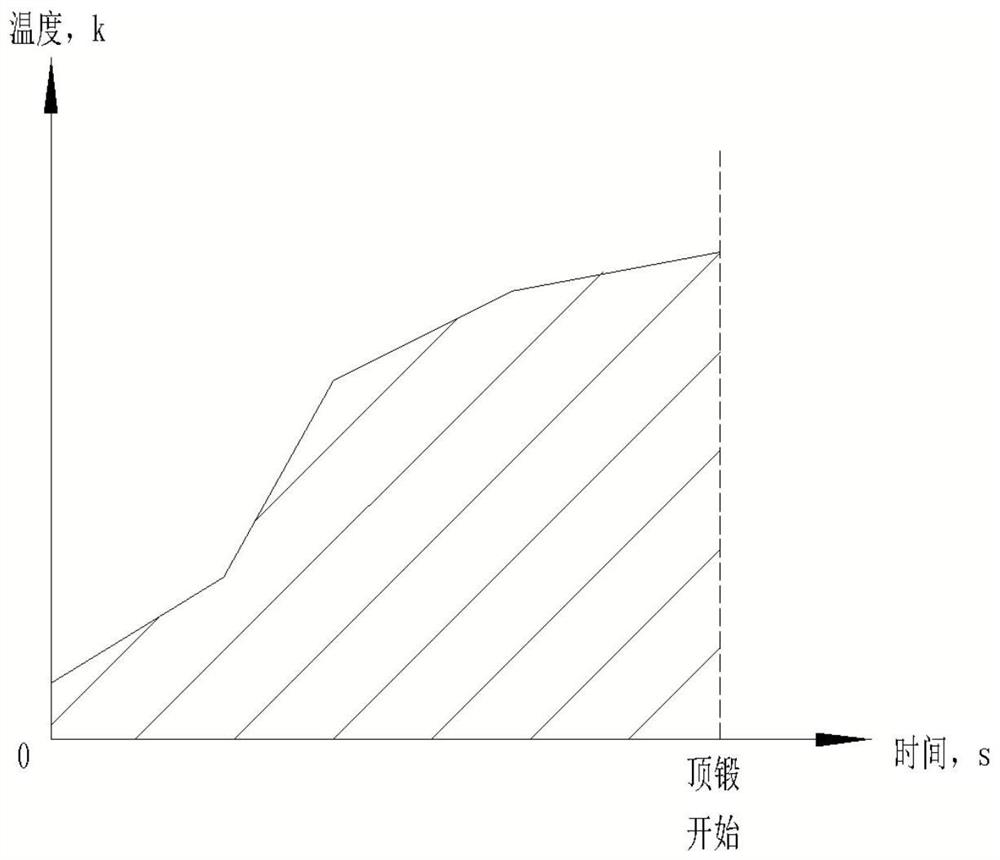

[0034] Such as Figure 1~2 As shown, a friction welding control and quality evaluation method based on weld seam temperature and spatter detection is characterized in that: friction welding is performed using a friction welding control system, and the friction welding control system includes a welding machine platform 10, a welding machine rotating end 20, Welding machine mobile terminal 30, oil pressure station 40, spatter detection device 50, infrared thermal imaging camera 60, industrial computer 70 and welding machine control system 80; above, and the rotating end 20 of the welding machine is controlled by the main shaft of the rotating end, and the moving end 30 of the welding machine is controlled by the main shaft of the moving end; holding; the splash detection device 50 is a detachable structure, which is composed of two semi-arc-type detection components, and the inner wall of the semi-circle-arc type detection component is evenly distributed with high-sensitivity im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com