Reinforcing agent for paper surface sizing and preparation method thereof

A surface sizing and strengthening agent technology, applied in papermaking, paper coating, water repellent addition, etc., can solve the problems of difficulty in forming a continuous and complete film, affecting paper strength, and poor moisture resistance, so as to improve product utilization efficiency, improving paper strength, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 reinforcing agent

[0023] The steps are:

[0024] 1) Add 105g of water and 48g of tapioca starch into a 500ml reactor, start stirring and dissolving, heat up to 44°C, and keep warm for 0.2h;

[0025] 2) After constant temperature, add 15g of hydrogen peroxide solution (30%) dropwise, finish adding dropwise for 0.7h, and keep warm for 1.3h after dropping;

[0026] 3) Add 12g of polyvinyl alcohol (grade 0599), 100g of water, and keep warm for 0.5h;

[0027] 4) Then heat up to 95°C and keep warm for 2.5h;

[0028] 5) Cool down to 75°C, add 5g of ammonium persulfate aqueous solution (0.7g of ammonium persulfate, 4.3g of water) dropwise, finish the dropwise addition for 0.5h, and keep warm for 2h after the dropwise addition. The solution was cooled to room temperature to obtain the enhancer.

Embodiment 2

[0029] The preparation of embodiment 2 reinforcing agent

[0030] The steps are:

[0031] 1) Add 81g of water and 40g of cornstarch into a 500ml reactor, start stirring and dissolving, heat up to 45°C, and keep warm for 0.4h;

[0032] 2) After constant temperature, add 13.5g of hydrogen peroxide solution (30%) dropwise, finish adding dropwise for 0.6h, and keep warm for 1.5h after dropping;

[0033] 3) Add 10.4g of polyvinyl alcohol (grade 1799), 100g of water, and keep warm for 0.6h;

[0034] 4) Then heat up to 93°C and keep warm for 2.5h;

[0035] 5) Cool down to 75°C, add 5g of ammonium persulfate aqueous solution (0.5g of ammonium persulfate, 4.5g of water) dropwise, finish the dropwise addition in 0.4h, and keep warm for 2.5h after the dropwise addition. The solution was cooled to room temperature to obtain the enhancer.

Embodiment 3

[0036] The preparation of embodiment 3 reinforcing agent

[0037] The steps are:

[0038] 1) Add 98g of water and 50g of barley starch into a 500ml reactor, start stirring and dissolving, heat up to 46°C, and keep warm for 0.3h;

[0039] 2) After constant temperature, add 17g of hydrogen peroxide solution (30%) dropwise, finish adding dropwise for 0.5h, and keep warm for 1.2h after dropping;

[0040] 3) Add polyvinyl alcohol (grade 0588) 12g, water 120, keep warm for 0.7h;

[0041] 4) Then heat up to 95°C and keep warm for 3h;

[0042] 5) Cool down to 75°C, add 5g of ammonium persulfate aqueous solution (0.8g of ammonium persulfate, 4.2g of water) dropwise, finish the dropwise addition in 0.8h, and keep warm for 2h after the dropwise addition. The solution was then cooled to room temperature to obtain the enhancer.

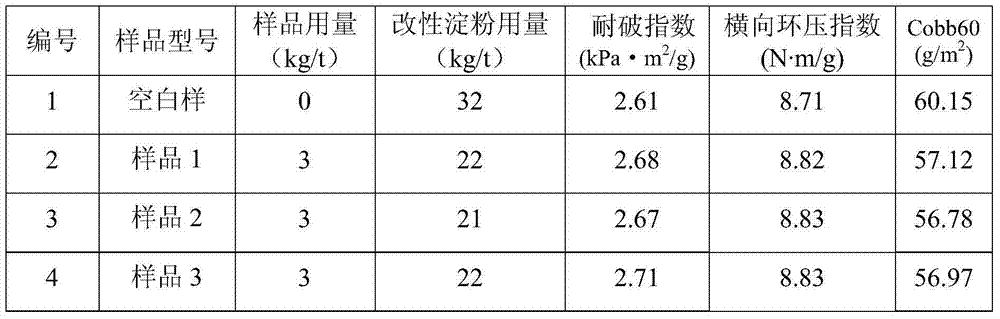

[0043] The reinforcing agent and modified starch prepared in Examples 1 to 3 are used for surface sizing of kraft cardboard, and the paper-forming performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com