Traceable logistics box capable of being rejected midway and work method thereof

A logistics box and logistics technology, applied in logistics, bottle/can parts, containers, etc., can solve the problems of waste of logistics capacity, return and exchange of goods, and it is difficult to ensure the integrity of the logistics box. Utilization and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing.

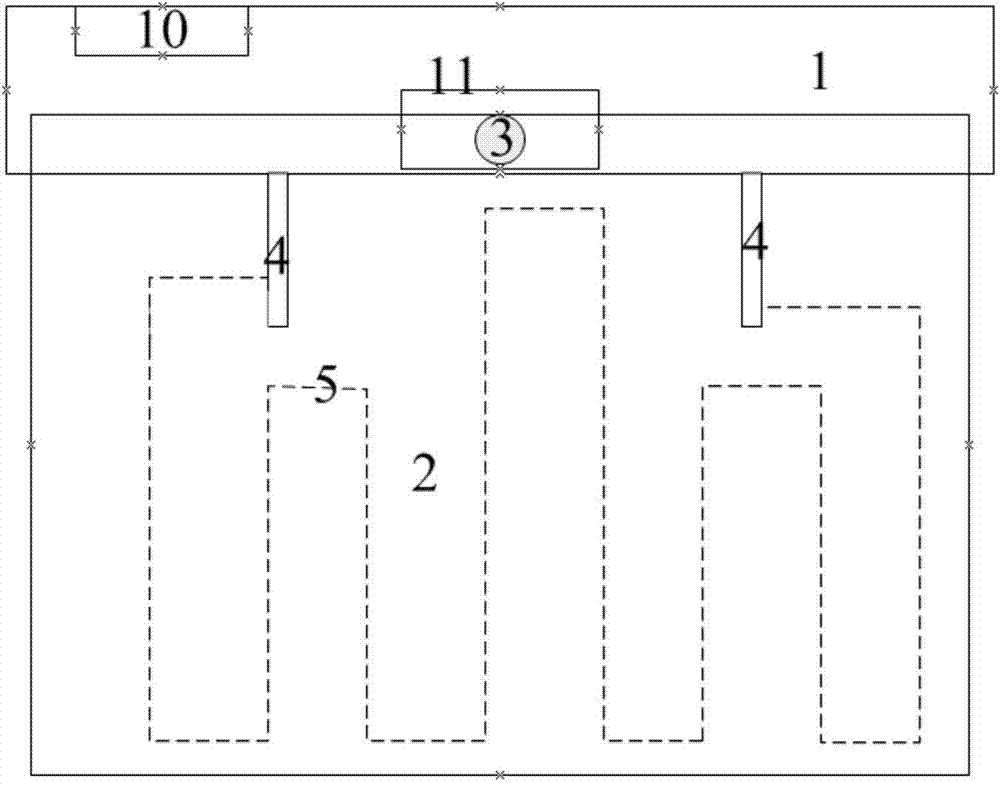

[0064] Such as figure 1 Shown, the present invention is made of box cover 1 and box body 2. What case lid 1 and casing 2 adopted are all environmental-friendly engineering plastics to make, and the connection between the two is to pass through case lid connection column 8 and casing lead hole 4. Its connection standard is that the electronic lock 11 on the box cover and the lock hole 3 on the box body can realize complete docking.

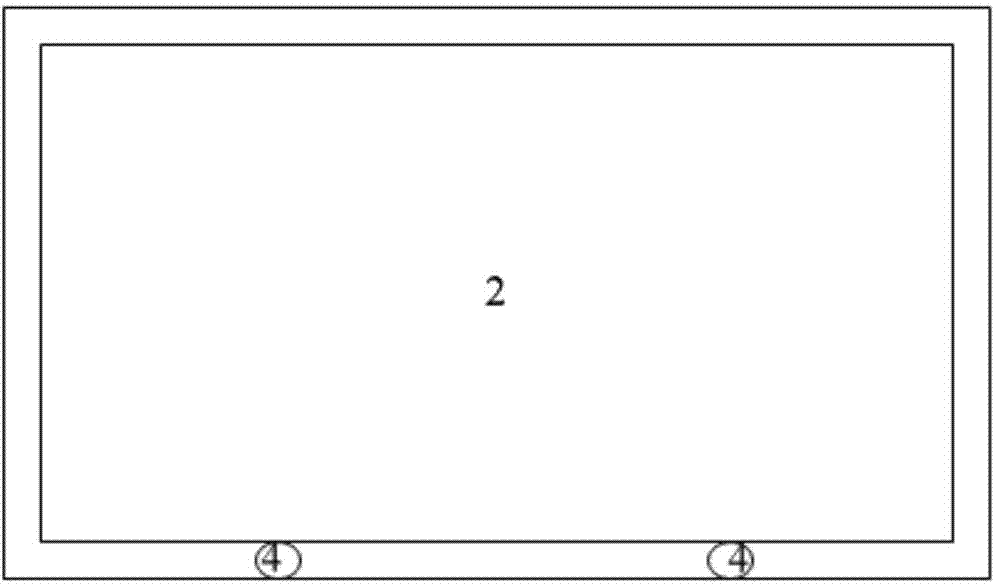

[0065] Such as figure 2 Shown, there are two casing lead holes 4 on the front side wall of casing 2, and casing lead hole 4 is connected with the copper wire circuit 5 on the casing, and its hollow part is connected with case cover connection column 8.

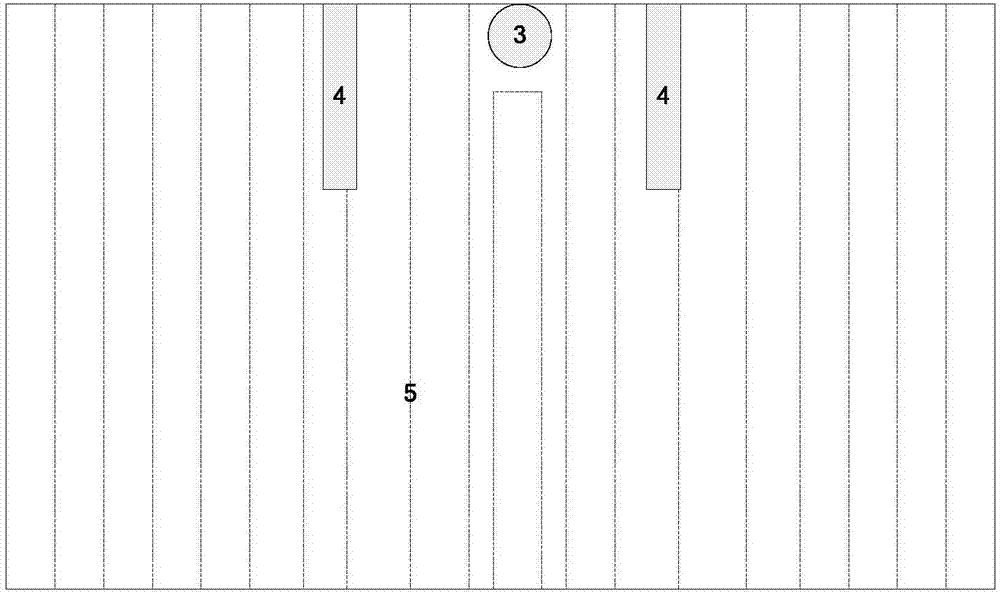

[0066] Such as image 3 As shown, each surface of the box body 2 is embedded with a copper wire circuit 5 in advance during the manufacturing process. During the process of embedding the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com