Manufacturing method of bamboo fiber shaving board

A manufacturing method and technology of particleboard, applied in the direction of manufacturing tools, joining of wooden veneers, machining of plant materials, etc., can solve the problems of inability to meet the growing needs of the market, slow growth of wood resources, and damage to the ecological environment, and achieve The internal structure is not easily deformed, the internal structure is uniform, and the effect of reducing the content of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of manufacture method of bamboo fiber particleboard, comprises the following steps:

[0021] 1) Bamboo shavings are removed from impurities, and after being dried in a drier, they are sent to the core layer shavings hopper, and MDI glue is added to the core layer sizing machine to sizing the core layer shavings, and the moisture content of the core layer shavings is controlled to be 10%; The bamboo shavings entrance of the core layer sizing machine is provided with a screw transport device.

[0022] 2) After cleaning the bamboo shavings, send them to the thermal mill, add paraffin, add modified UF glue and send them to the surface fiber silo after drying, control the moisture content of the surface fiber material to 8%; the bamboo shavings are processed bamboo products. Made from bamboo scraps.

[0023] 3) use five-head paving machine, step 2) gained surface layer fiber material is sent into upper and lower surface layer paving heads 1 and 5, and step 1) gained ...

Embodiment 2

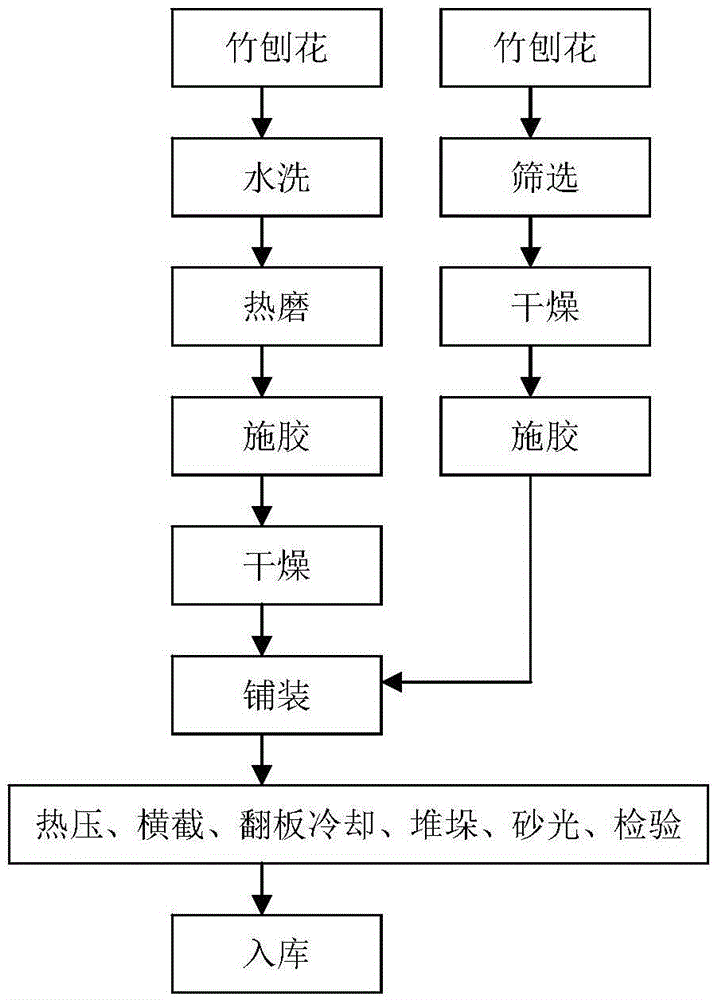

[0027] A kind of manufacture method of bamboo fiber particle board, it is such as figure 1 The manufacture method of shown bamboo fiber particle board specifically comprises the steps:

[0028] 1) The bamboo shavings are removed by impurity cleaning equipment and sent to the dryer for drying. After screening, they are sent to the core shaving silo. The length of the shavings is controlled to be 12-20mm, width 5-10mm, and thickness 0.35-0.7mm.

[0029] 2) Wash the bamboo shavings and send them to the thermal grinder, add paraffin wax, add modified UF glue and dry them, then send them to the surface fiber silo, control the sizing amount to 8-12%, and the moisture content to 7-10%.

[0030] 3) Apply the MDI glue to a sizing machine with an auger at the entrance, control the glue amount of the core layer shavings after sizing to 3-6%, and the moisture content to 8-12%.

[0031] 4) Use a five-head paving machine to send bamboo fibers into the upper and lower surface paving heads 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com