Drafting twisting machine

A twisting machine and drafting technology, which is applied in the field of drafting and twisting machines, can solve problems such as easy occurrence of fuzz, inconvenient operation, and high power consumption, and achieve the effects of low noise, convenient operation, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

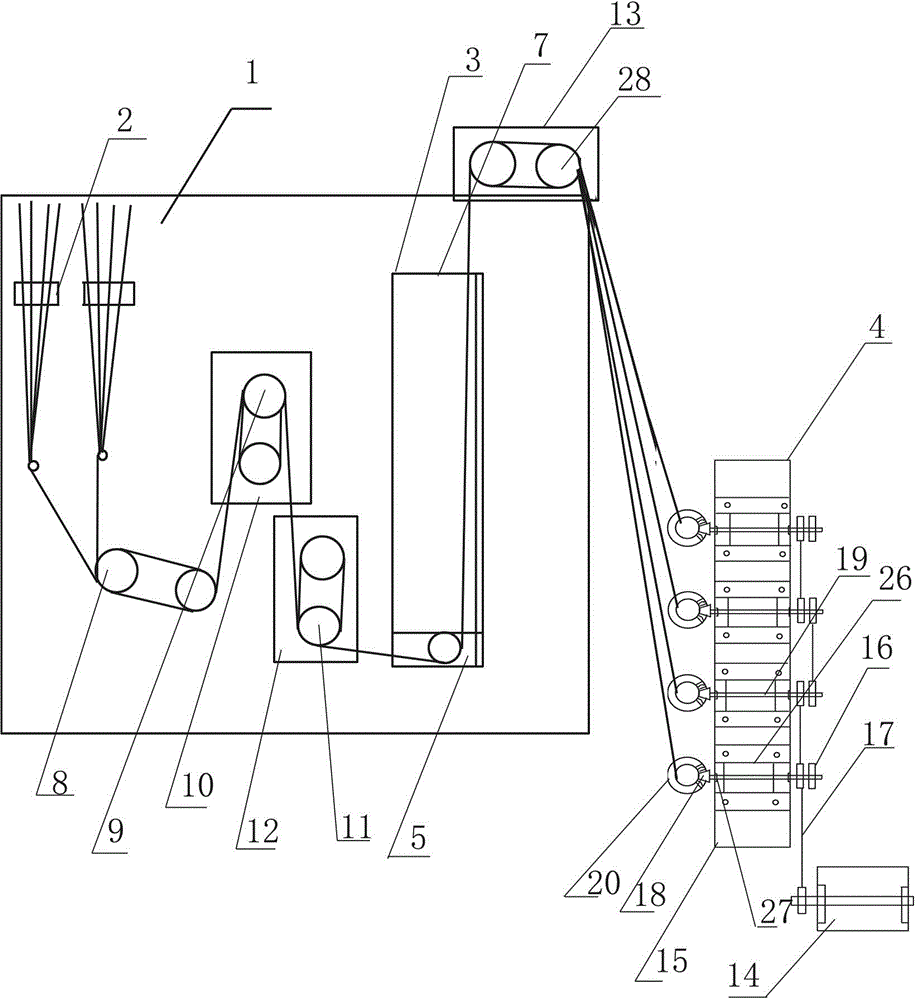

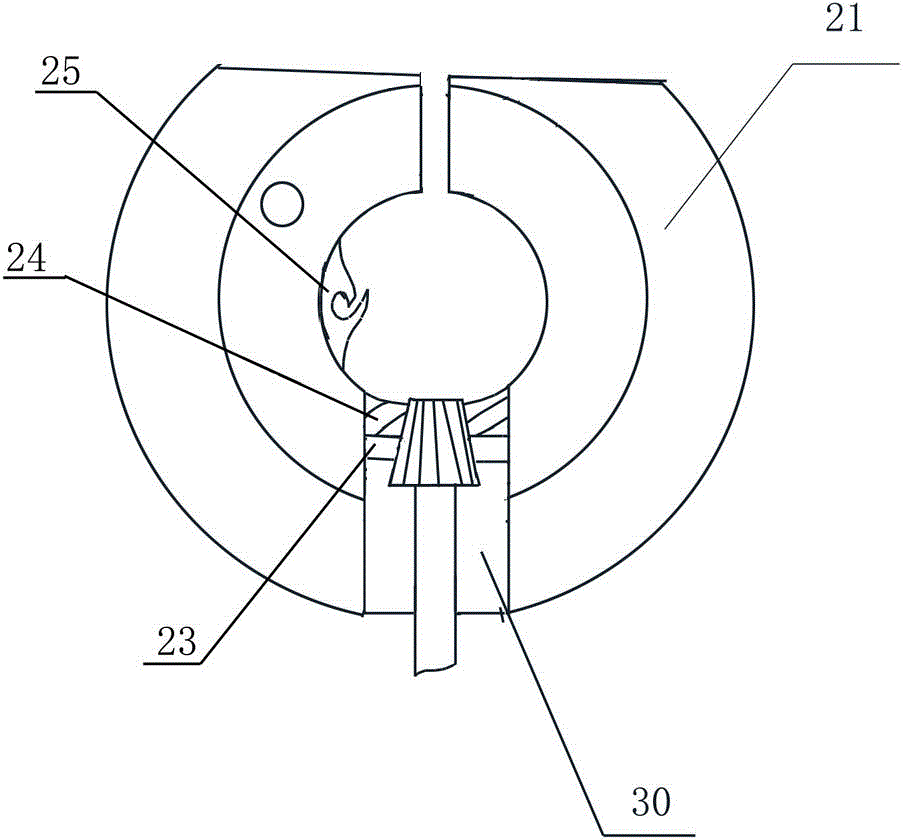

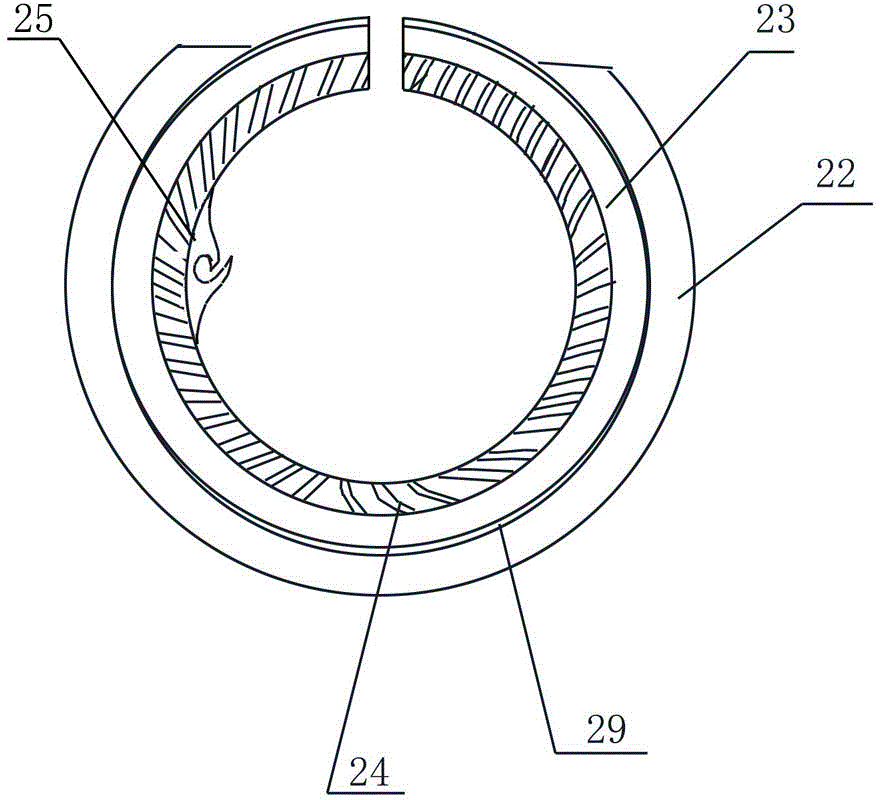

[0012] exist figure 1 , figure 2 and image 3 Among them, the present invention provides a draft twisting machine, which is provided with a support frame 1, a number of wire feed frames 2 are provided on one side of the surface of the support frame 1, and a drafting roller assembly I is provided on the support frame 1. , drafting roller assembly II, drafting roller assembly III and heating box 3, drafting roller assembly IV is provided on the top of support frame 1, and twister 4 is provided on the other side of support frame 1, each The strands enter the wire frame 2 and then pass through the drafting roller assembly I, the drafting roller assembly II, the drafting roller assembly III, the heating box 3 and the drafting roller assembly IV, and then enter the twisting machine 4 , the drafting roller assembly I is arranged obliquely on the support frame 1, the drafting roller assembly I is provided with two rollers I8, and the two rollers I8 are side by side and then incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com