Alternate twill knitted net of blended yarn with multicolor jacquard

A technology of blended yarn and knitted net, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of easy hardening of Tencel fiber, insufficient fluffiness, poor shrinkage of Optim fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

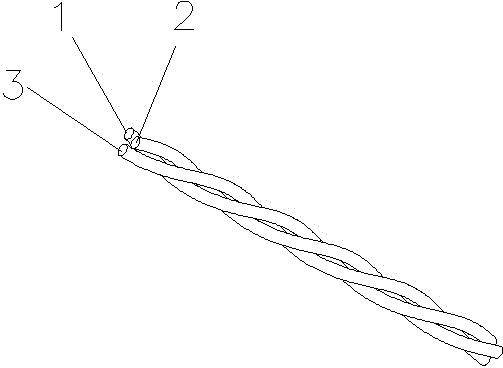

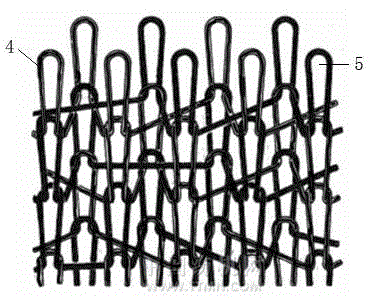

[0024] The blended yarn multi-color jacquard spaced twill knitted net is composed of total yarn 4, which is composed of cotton yarn 1, cellulose yarn 2 and modified wool yarn 3 intertwined, and is passed through block polyether amino Finished with polysiloxane finishing agent. Part of the total yarn 4 forms the yarn coil 5 through weaving, and the rest of the total yarn 4 floats on the front of the yarn coil 5 in the shape of a floating thread and forms a floating flower, and the floating flower is wound and fixed by the total yarn 4 and the yarn coil 5 And form the sesame dot pattern on the reverse side of the yarn loop 5.

[0025] Cotton yarn 1 is preferably long-staple cotton with a count of 5500 Nm and a maturity of 1.7, that is, the fiber length of cotton yarn 1 is 36 μm, the fineness is 8000 m / g, the width is 15.5 μm, and the strength is 4.5 grams per strand. The breaking length is 38km, the torsion is 100 pieces / cm; the fiber length of cellulose yarn 2 is 38 μm; the fi...

Embodiment 2

[0034] The difference from Example 1 is that the cotton yarn 1 is preferably long-staple cotton with a count of 5400 Nm and a maturity of 1.6, that is, the fiber length of the cotton yarn 1 is 33 μm, the fineness is 7000 m / g, and the width is 15 μm , the strength is 4 gf / string, the breaking length is 33 km, and the torsion is 80 pieces / cm; the fiber length of cellulose yarn 2 is 30 μm; the fiber length of modified wool yarn 3 is 28 μm.

Embodiment 3

[0036] The difference from Example 1 is that cotton yarn 1 is preferably long-staple cotton with a count of 5600 Nm and a maturity of 1.8, that is, the fiber length of cotton yarn 1 is 39 μm, the fineness is 8500 m / g, and the width is 16 μm , the strength is 5 gf / string, the breaking length is 40 km, and the torsion is 120 pieces / cm; the fiber length of cellulose yarn 2 is 45 μm; the fiber length of modified wool yarn 3 is 35 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com