Tension adjusting mechanism of loom

A tension adjustment mechanism and loom technology, which are applied in the directions of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of poor weaving effect, no tension adjustment structure, etc., and achieve good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

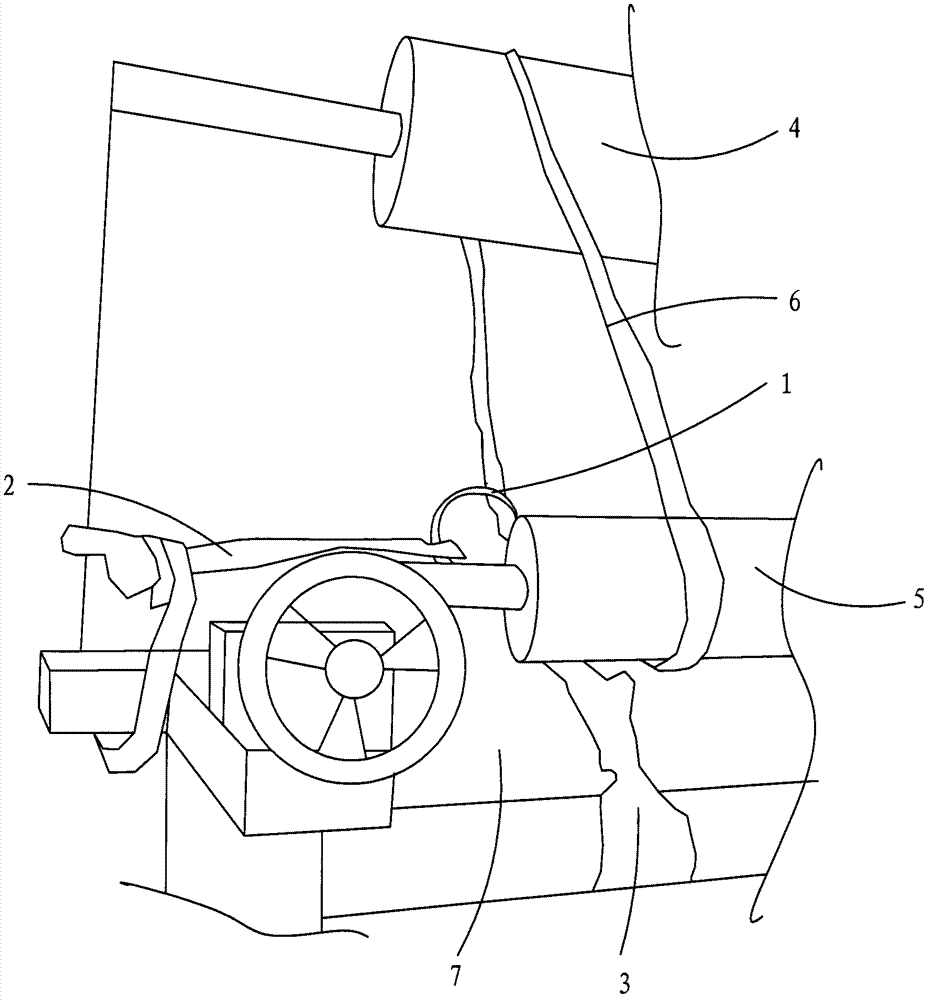

[0010] as attached figure 1 As shown, a tension adjustment mechanism of a loom includes an iron ring 1, a first traction rope 2 connected to the iron ring 1 at one end, and a second traction rope 2 connected at one end to the iron ring 1. The traction rope 3, the third traction rope 6 that passes through the iron ring 1 and is wound on the upper roll 4 and the lower roll 5, the other end of the first traction rope 2 part is fixedly connected with the frame 7, and the other end of the second traction rope 3 is fixedly connected with the frame 7.

[0011] The iron ring 1 is a closed iron ring 1 .

[0012] As mentioned above, we have fully described according to the purpose of the present invention, but the present invention is not limited to the above-mentioned embodiments and implementation methods. Practitioners in the relevant technical fields may make various changes and implementations within the scope permitted by the technical ideas of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com