Automatic production line of uvioresistant tarpaulin roller

An automatic production line and anti-ultraviolet technology, which is applied to the removal of liquid/gas/steam with squeeze rollers, continuous processing of textile materials, and processing of textile material drums, etc. It can solve problems such as difficult clothing, poor air permeability, cracks, etc., to achieve Reduces defects such as needle marks, reduces processing steps, and improves weavability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

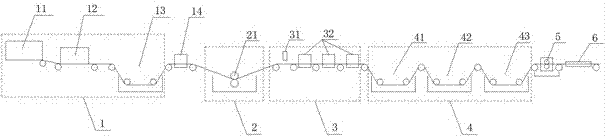

[0021] like figure 1 As shown, the anti-ultraviolet tarpaulin roller automatic production line of the present invention includes a weaving area 1, a dyeing area 2, a baking area 3 and a cleaning area 4, and the weaving area 1, dyeing area 2, baking area 3 and cleaning area 4 connected in sequence, the weaving area 1 is provided with a raw material moisture rejuvenation machine 11, a weaving machine 12, a gray cloth cleaning machine 13 and a gray cloth drying machine 14, and the outlet of the raw material moisture rejuvenation machine 11 is connected with the feeding port of the weaving machine 12 , the discharge port of the weaving machine 12 is connected with the feed port of the gray cloth cleaning machine 13, the discharge port of the gray cloth cleaning machine 13 is connected with a gray cloth drying machine 14, and a padding car 21 is arranged in the dyeing area 2 , the rolls of the padding car 21 are located in the dyeing box with ultraviolet absorbers, the discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com