A kind of whole bio-based anti-ultraviolet type mosquito repellent microcapsule and preparation method thereof

A microcapsule, bio-based technology, applied in microcapsule preparations, botanical equipment and methods, microsphere preparation, etc., can solve the problems of adding anti-ultraviolet chemical treatment procedures, complex preparation processes, emulsifier residues, etc. Market application prospect, uniform particle size, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

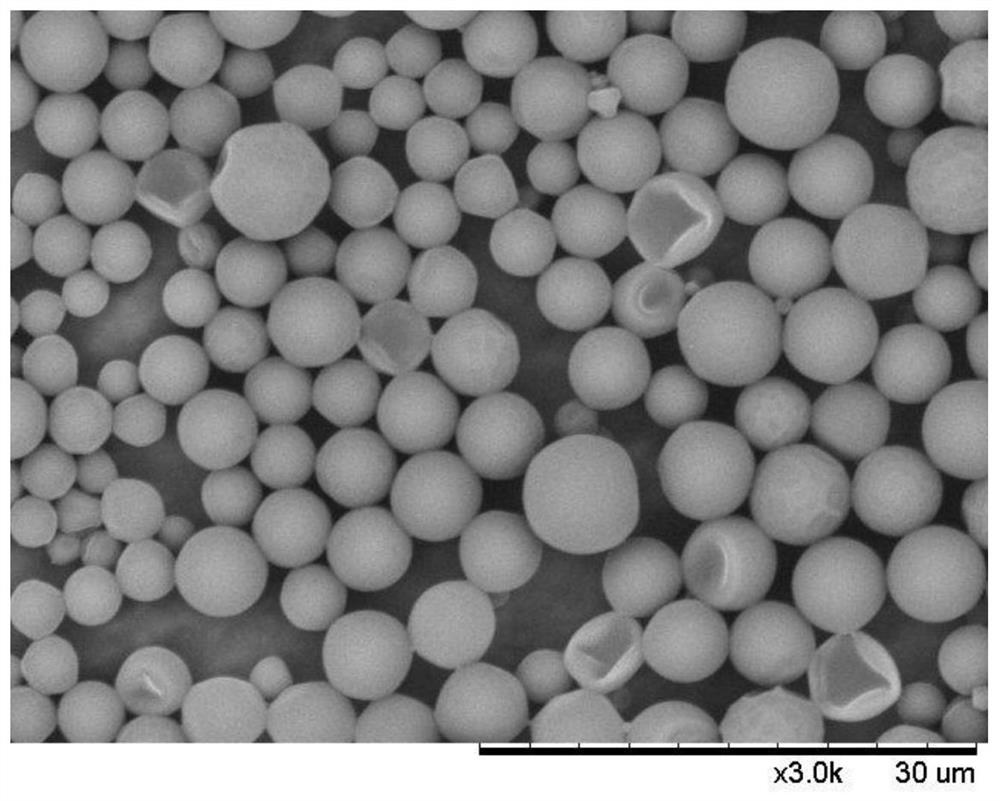

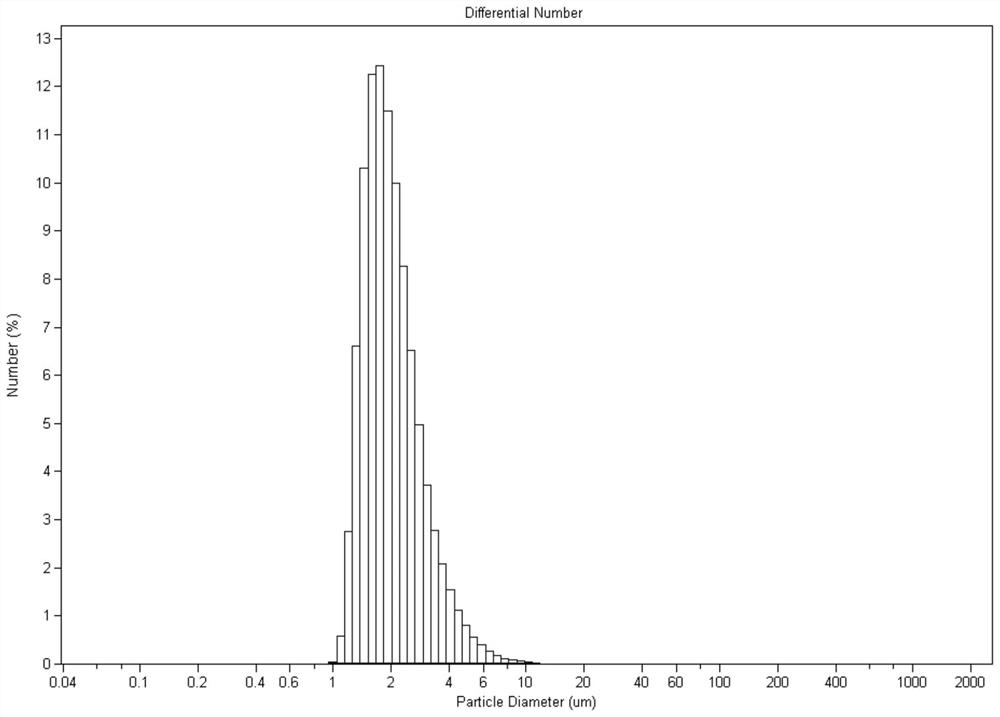

[0035] First, 10 g of polylactic acid and 10 g of citronella oil were weighed and dissolved in 20 mL of dichloromethane solution to form an oil phase, and 0.8 g of alkali lignin was weighed and dispersed in 40 mL of water to form a water phase under the action of magnetic stirring. The oil-in-water emulsion is prepared by using an internal pressure Shirasu porous glass membrane (SPG membrane) emulsifier. The specific process of emulsion preparation is: under the action of nitrogen pressure, the oil phase passes through the SPG membrane (pore size is 1 μm), thereby forming oil on the surface of the membrane. Under the flushing action of the water phase, the oil phase droplets are peeled off from the membrane surface to obtain an oil-in-water emulsion.

[0036] Then, the oil-in-water emulsion was stirred for 12 hours with a magnetic stirrer under normal temperature and pressure conditions to evaporate and remove the solvent dichloromethane, so that the microcapsules were solidifi...

Embodiment 2

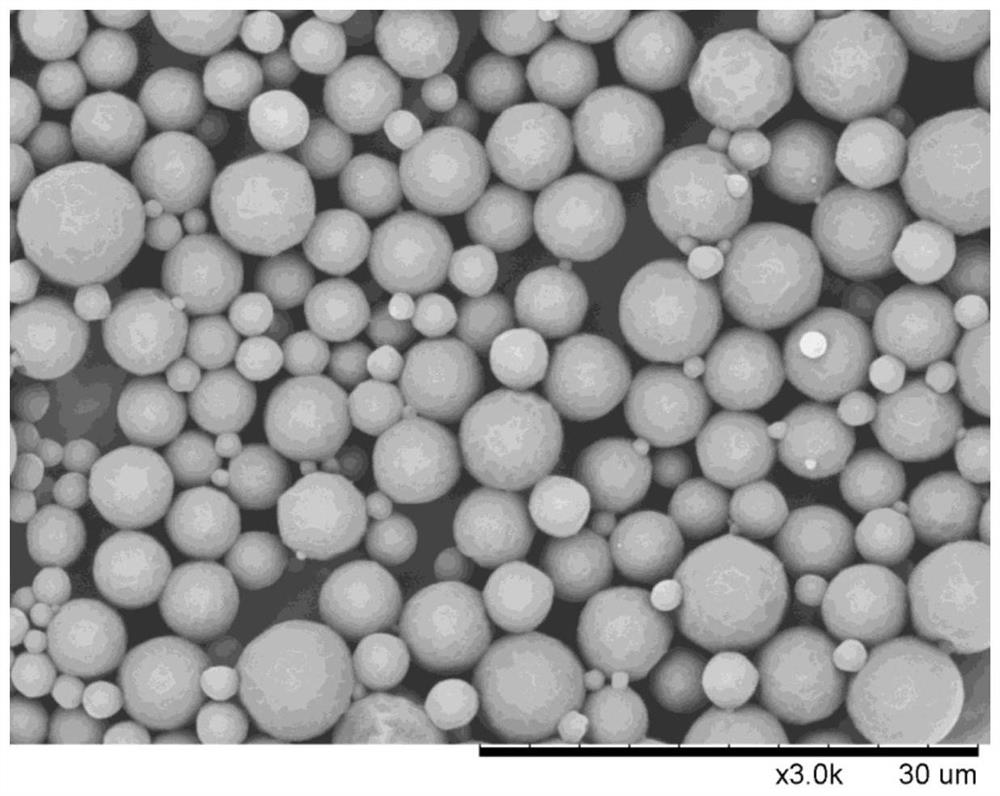

[0039] First, 10 g of polylactic acid and 10 g of lemon eucalyptus oil were dissolved in 20 mL of dichloromethane solution to form an oil phase, and 0.8 g of alkali lignin was weighed and dispersed in 40 mL of water to form a water phase under the action of magnetic stirring. The oil-in-water emulsion is prepared by using an internal pressure Shirasu porous glass membrane (SPG membrane) emulsifier. The specific process of emulsion preparation is: under the action of nitrogen pressure, the oil phase passes through the SPG membrane (pore size is 0.5 μm), thereby forming on the surface of the membrane. Oil phase droplets, under the flushing action of the water phase, the oil phase droplets are peeled off from the membrane surface to obtain an oil-in-water emulsion.

[0040] Then, the oil-in-water emulsion was stirred for 15 hours with a magnetic stirrer under normal temperature and pressure conditions to evaporate and remove the solvent dichloromethane, so that the microcapsules w...

Embodiment 3

[0043] First, 6.67g polylactic acid and 13.33g citronella oil were weighed and dissolved in 20mL dichloromethane solution to form an oil phase, and 0.9g sodium lignosulfonate was weighed and dispersed in 40mL water to form a water phase under the action of magnetic stirring. The oil-in-water emulsion is prepared by using an internal pressure Shirasu porous glass membrane (SPG membrane) emulsifier. The specific process of emulsion preparation is: under the action of nitrogen pressure, the oil phase passes through the SPG membrane (pore size is 0.2 μm), thereby forming on the surface of the membrane. Oil phase droplets, under the flushing action of the water phase, the oil phase droplets are peeled off from the membrane surface to obtain an oil-in-water emulsion.

[0044] Then, the oil-in-water emulsion was stirred for 12 hours with a magnetic stirrer under normal temperature and pressure conditions to evaporate and remove the solvent dichloromethane, so that the microcapsules we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com