Dyeing method for enhancing mechanical performances of cotton stems

A dyeing method and stalk technology, applied in wood treatment, wood processing equipment, impregnated wood, etc., can solve the problem that cotton stalks cannot be used well, the mechanical properties of cotton stalks are not ideal, and the color of cotton stalks is single Dimness and other problems, to achieve the effect of improving the use value and effect, promoting the penetration effect, and the color is bright and shiny

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

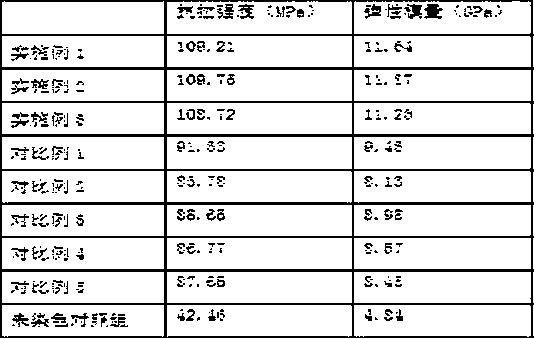

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a dyeing method for enhancing the mechanical properties of cotton stalks, the specific method is as follows:

[0019] (1) Place the cotton stalks in a constant temperature steam treatment at 113°C for 18 minutes, take them out, place them in a constant temperature freezer at -9.6°C for 48 minutes, take them out, and place them in a constant temperature at 151°C Steam treatment for 14 minutes, take out, and cool down;

[0020] (2) Submerge the cotton stalks treated in step (1) in an aqueous solution of aluminum sulfate with a mass fraction of 7.7% and a temperature of 45°C for 56 minutes, drain and remove, and dry by hot pressing;

[0021] (3) Submerge the cotton stalks treated in step (2) in the dyeing agent for 52 minutes and pass through ultrasonic waves for ultrasonic treatment, remove the agent, and dry to constant weight;

[0022] The preparation method of described staining agent specifically comprises the following ste...

Embodiment 2

[0030] In the embodiment of the present invention, a dyeing method for enhancing the mechanical properties of cotton stalks, the specific method is as follows:

[0031] (1) Place the cotton stalks in a constant temperature steam treatment at 117°C for 19 minutes, take them out, put them in a constant temperature freezing treatment at -9.4°C for 51 minutes, take them out, and place them in a constant temperature at 155°C Steam treatment for 15 minutes, take out, and cool down;

[0032] (2) Submerge the cotton stalks treated in step (1) in an aluminum sulfate aqueous solution with a mass fraction of 7.9% and a temperature of 46°C for 62 minutes, drain and remove, and dry by hot pressing;

[0033] (3) Submerge the cotton stalks treated in step (2) in the dyeing agent for 56 minutes, pass through ultrasonic waves for ultrasonic treatment, remove the agent, and dry to constant weight;

[0034] The preparation method of described staining agent specifically comprises the following ...

Embodiment 3

[0042] In the embodiment of the present invention, a dyeing method for enhancing the mechanical properties of cotton stalks, the specific method is as follows:

[0043] (1) Place the cotton stalks in a constant temperature steam treatment at 121°C for 20 minutes, take them out, place them in a constant temperature freezer at -9.2°C for 54 minutes, take them out, and place them in a constant temperature at 159°C Steam treatment for 16 minutes, take out, and cool down;

[0044] (2) Submerge the cotton stalks treated in step (1) in an aqueous solution of aluminum sulfate with a mass fraction of 8.1% and a temperature of 47°C for 68 minutes, drain and remove, and dry by hot pressing;

[0045] (3) Submerge the cotton stalks treated in step (2) in the dyeing agent for 60 minutes, pass through ultrasonic waves for ultrasonic treatment, remove the agent, and dry to constant weight;

[0046] The preparation method of described staining agent specifically comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com