Reed door type shuttle rail pair

A technology of track pairs and reed gates, which is applied in textiles, textiles, papermaking, looms, etc., to achieve the effects of improving weaving performance, improving weaving reliability, and reducing strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

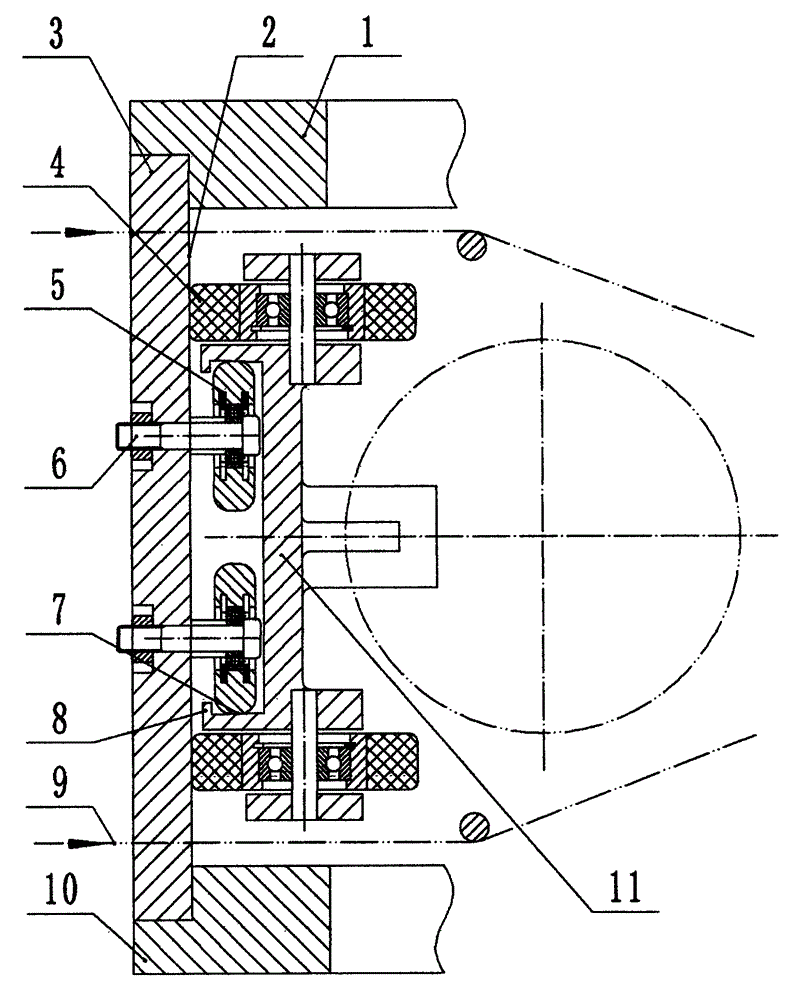

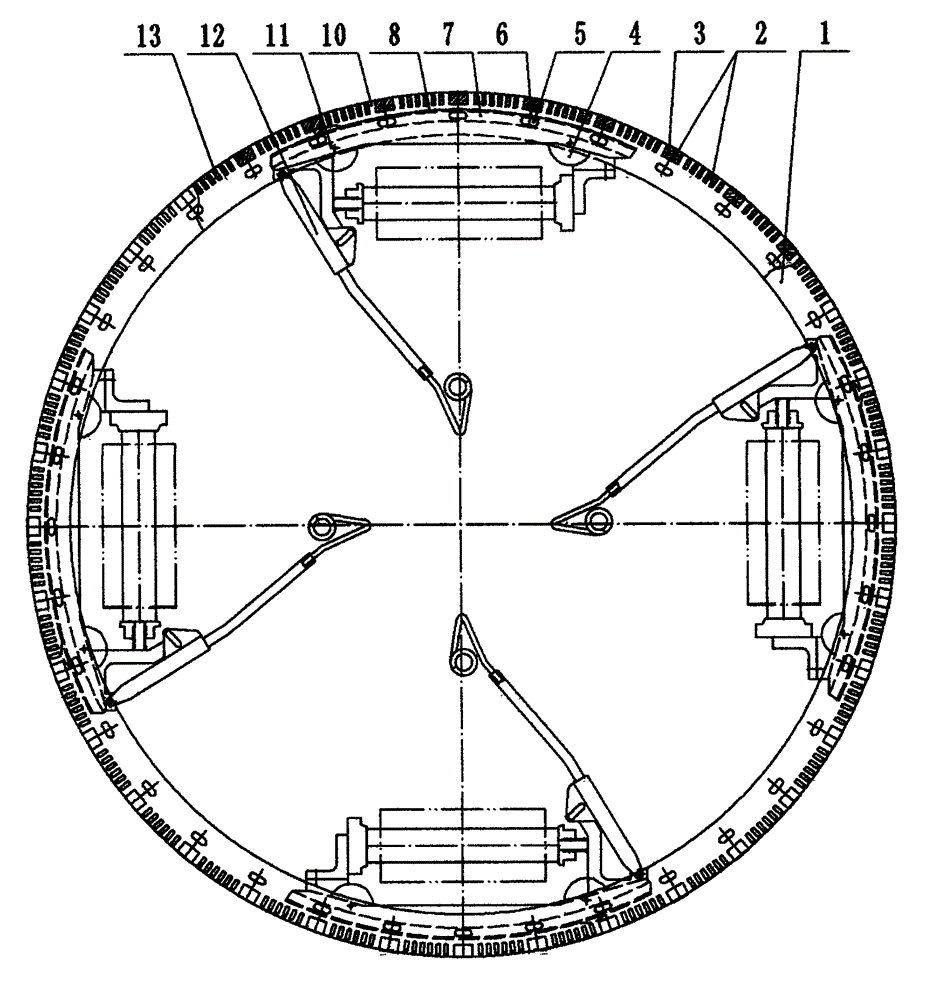

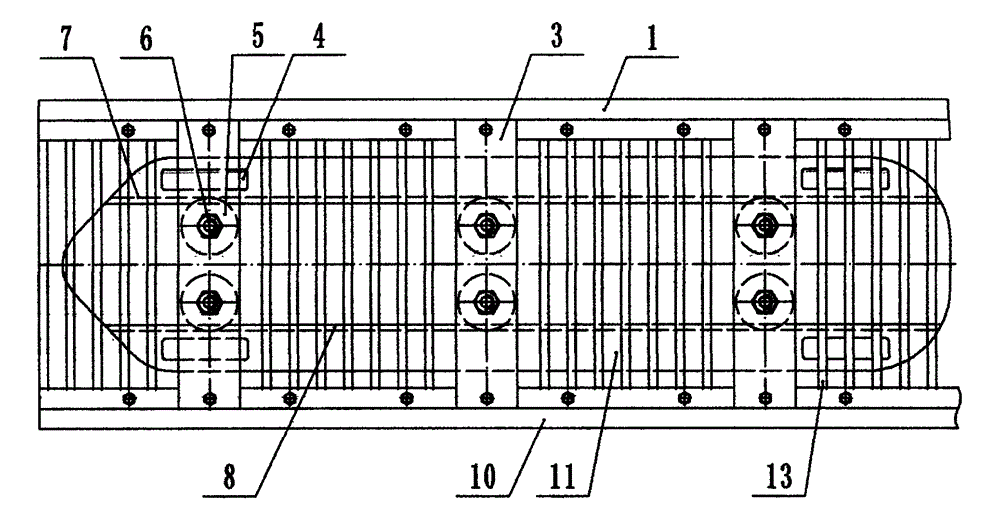

[0030] Such as Figure 1-6 As shown, a reed door type shuttle track pair is characterized in that it includes a reed door track, a built-in horizontal track and a shuttle, wherein:

[0031] The reed door track includes a number of thin slices 2 and inner sides of columns 3 arranged between the upper door ring 1 and the lower door ring 10;

[0032] The built-in horizontal track includes a column 3 and a roller 5 arranged on the column 3, the rollers 5 are in pairs up and down, and the rollers 5 are fixed on the column 3 through a shaft 6;

[0033] Described shuttle comprises shuttle body 11, the shuttle wheel 4 that is arranged on the shuttle body 11 and the notch 7 of shuttle body bottom surface;

[0034] The shuttle wheel 4 rolls and fits with the reed door track 2, and the notch 7 rolls and fits with the built-in horizontal track;

[0035] Warp thread 9 passes in the gap between upper door ring 1 and shuttle body 11 and lower door ring 10 and shuttle body 11 respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com