Stitch transfer cam of computer knitting machine

A technology of computerized flat knitting machine and transfer cam, which is applied in the field of transfer cam, can solve the problems of high failure rate and complex structure of transfer cam, and achieve the effects of reducing weight, improving knitting effect, reducing manufacturing cost and using cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

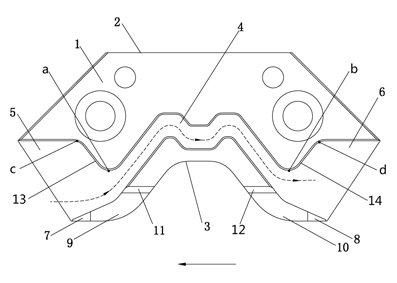

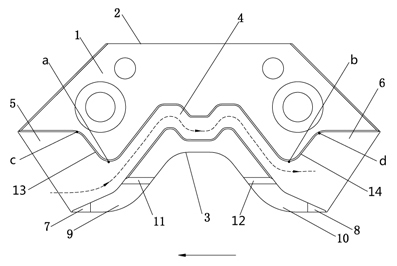

[0013] Referring to the drawings, this embodiment includes a left-right symmetrical body 1 with a straight top edge 2 and a U-shaped bottom edge 3 concave inward; the middle of the body 1 has an M-shaped groove 4. The two ends of the M-shaped groove 4 are oblique grooves extending to both sides of the main body 1 respectively, and the upper sides of the extension parts of the two ends are respectively inclined upward at positions a and b to form a first slope 13 and a second slope 14 , the extended parts of the first and second slopes 13, 14 intersect outwardly with the two sides of the body 1 at c and d respectively, forming two outwardly expanded first bell mouths 5 and second bell mouths 6, thereby penetrating the body 1. Form the needle track.

[0014] There are respectively a first plane 9 and a second plane 10 between the first and seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com