Ultrasonic testing method for concentration of liquid-solid two-phase flow

A technology of testing method and measuring method, which is applied to the analysis of fluid by using sound wave/ultrasonic wave/infrasonic wave, material analysis and measuring device by using sound wave/ultrasonic wave/infrasonic wave, which can solve the problem that the error of emission intensity change cannot be automatically corrected, the sensitivity is low, Errors cannot be automatically corrected, etc., to achieve the effect of eliminating unstable emission intensity, small size, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Measurement method of the present invention is:

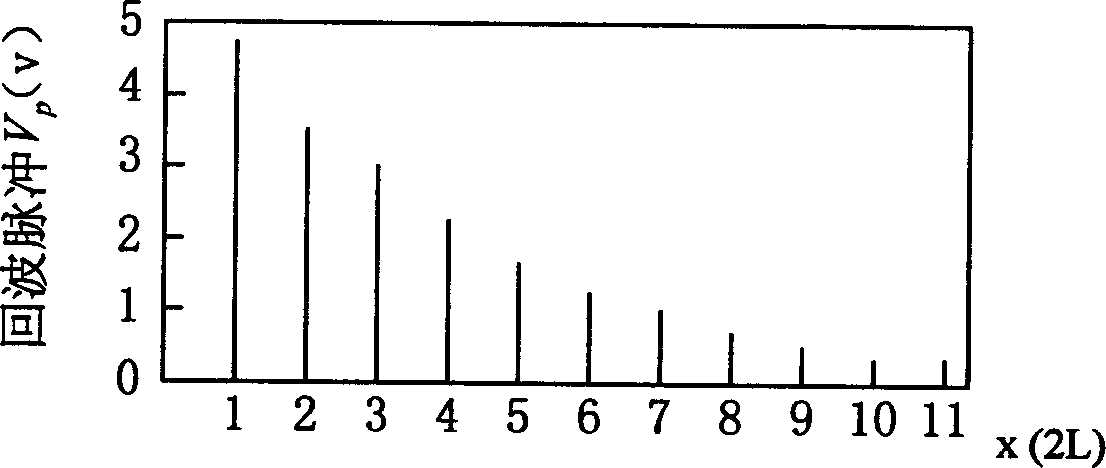

[0030] ①Use two parallel plates at a fixed interval, and the distance between them is about L=100mm; the ultrasonic probe is placed on one side of the parallel plate, and the ultrasonic wave is reflected back and forth between the two sides of the parallel plate (that is, the multiple pulse reflection method) to obtain multiple recovery , the medium between the parallel plates is the measured two-phase flow medium;

[0031] ②Under the same launch wave, the first, second and nth echoes are measured (the n echo is the last echo, and theoretically, each echo has an exponential decay law);

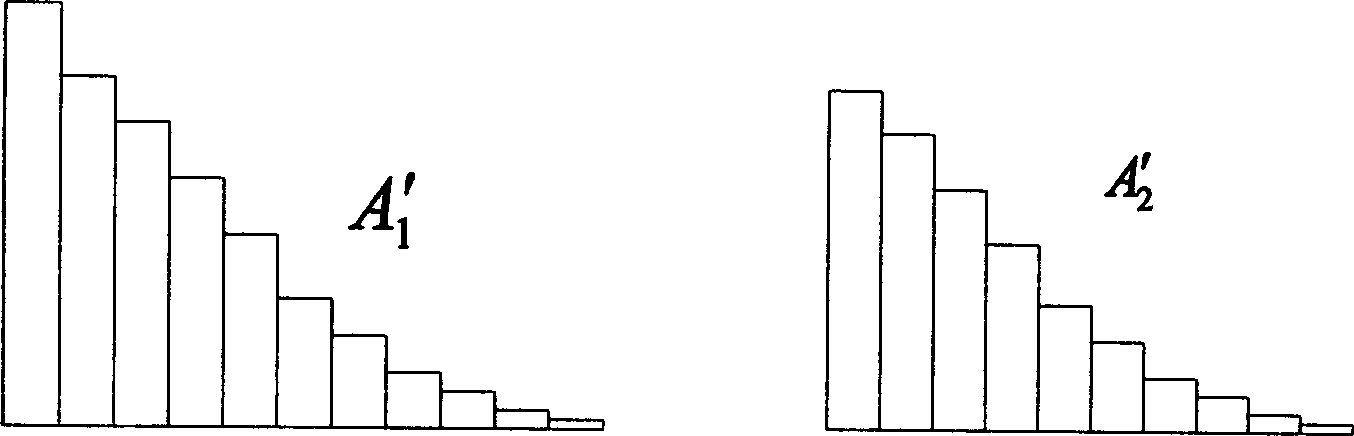

[0032] ③ Calculate the envelope area A1 of the first to nth echoes and the area A2 of the envelope of the second to nth echoes respectively;

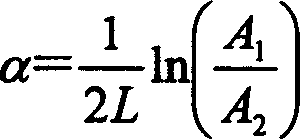

[0033] ④ Obtain the attenuation coefficient through formula calculation

[0034] α = 1 2 L ln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com