Dual cantilever adhesion sample thickness controller

A double cantilever and controller technology, applied in the preparation of test samples, etc., can solve problems such as deviation from the true value, affect the original bonding performance of the interface, and interface fracture, and achieve the effect of reducing self-weight and precisely controlling the thickness of the adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

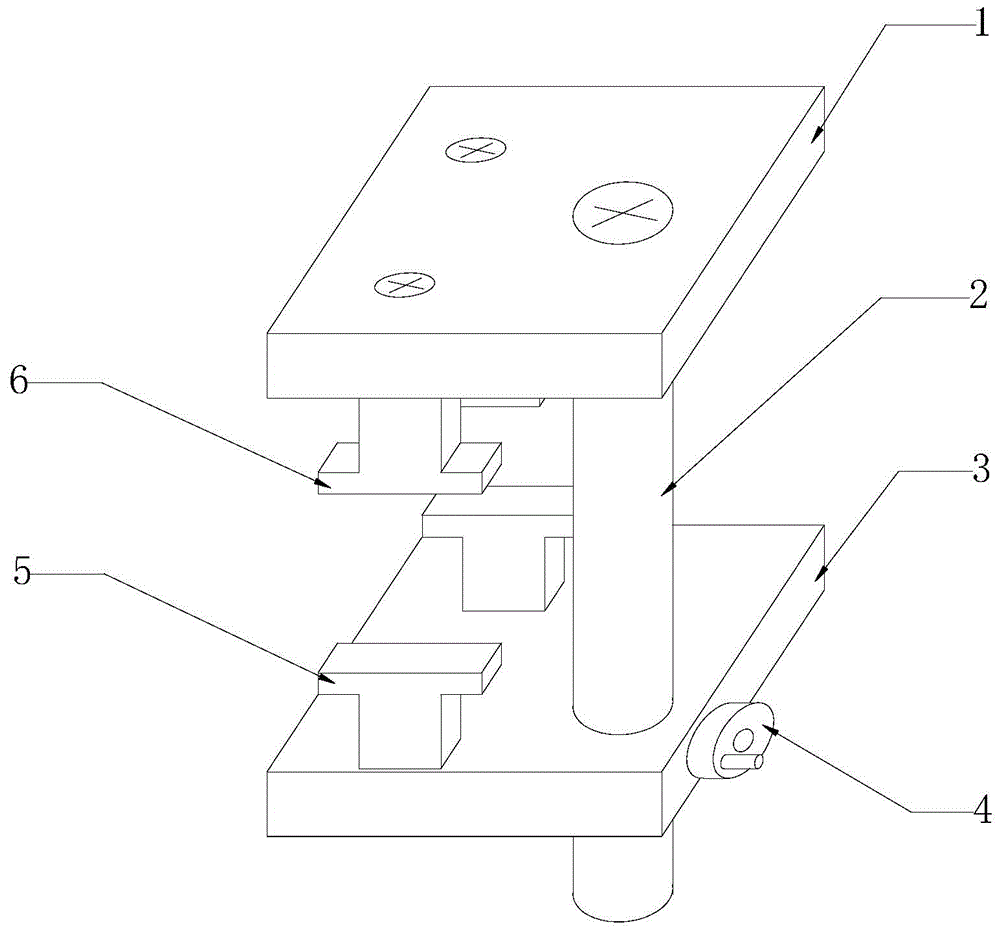

[0018] A double cantilever bonded sample thickness controller, comprising a base 1, a guide rod 2, a moving block 3, a handle 4, a lower support block 5, an upper support block 6, one end of the guide rod 2 is fixed with the base 1, and the other end Through the moving block 3, the moving block 3 is provided with a handle 4 that drives the moving block 3 to move along the guide rod 2. The upper end surface of the moving block 4 is provided with a lower support block 5, and the lower end surface of the base 1 is connected with the lower support block 5. The corresponding position is provided with an upper supporting block 6; the guide rod 2 and the moving block 3 are matched by a rack and pinion structure; In the groove, and slidingly fit with the groove; the lower support block 5 and the upper support block 6 are composed of two separate support blocks.

[0019] Its use in the process of making double cantilever bonded samples is as follows:

[0020] (1) Make double cantileve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com