Temperature and pressure synergistic gas adsorption, separation and purification system

A gas adsorption, adsorption separation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult and effective separation, and achieve the effect of improving heat exchange efficiency, realizing clean production and utilization, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

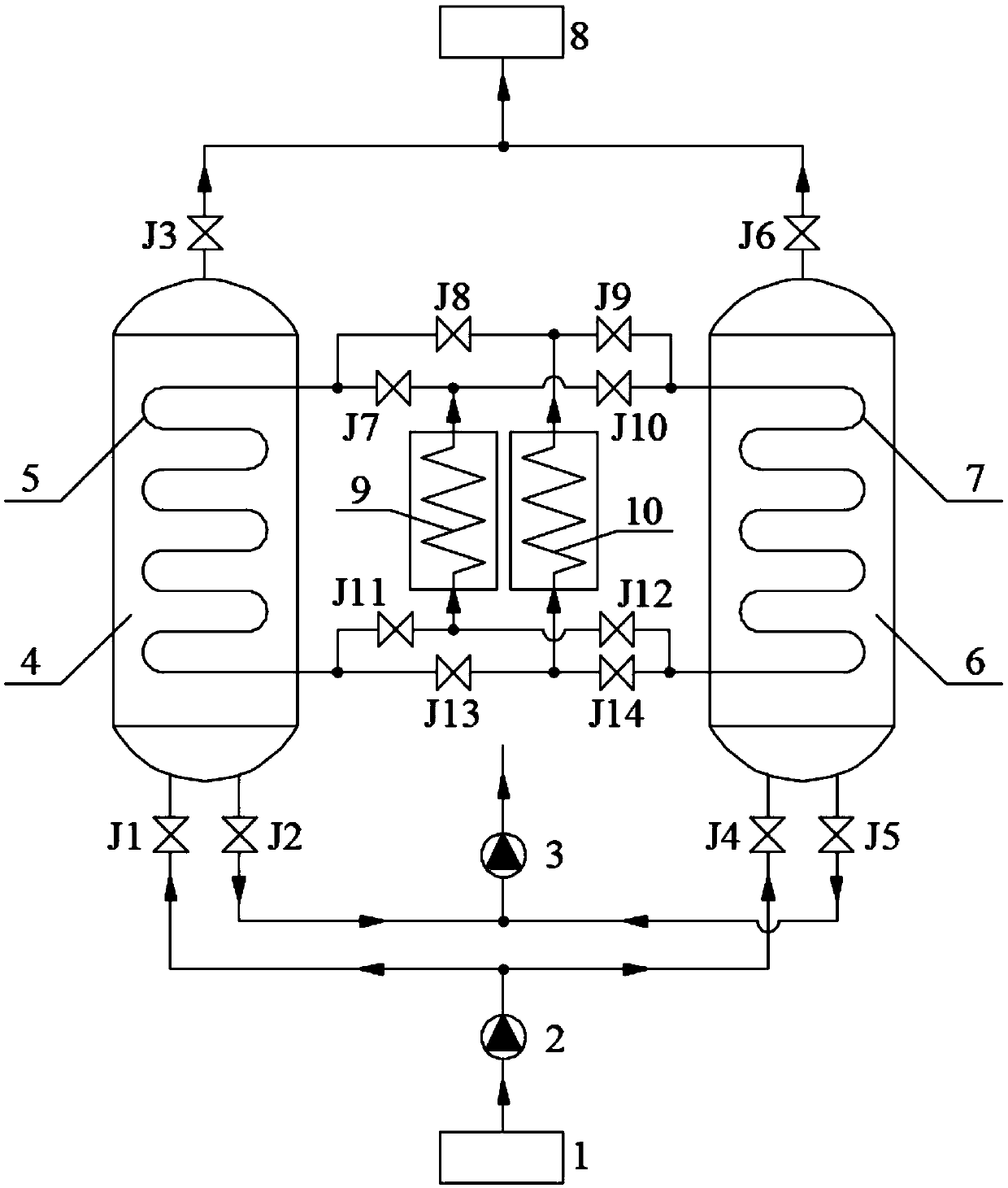

[0023] Such as figure 1 As shown, a temperature-pressure coordinated gas adsorption separation purification system includes an air intake unit 1, an exhaust unit 8, an adsorption separation unit and a temperature control unit,

[0024] Described adsorption separation unit comprises air compressor I2, vacuum pump 3, adsorption tower I4 and adsorption tower II6, the inlet end of described air compressor I2 is communicated with inlet unit 1, and the exhaust end of air compressor I2 is connected with adsorption tower respectively. The air inlets at the bottom of tower I4 and adsorption tower II6 are connected, the air outlets at the top of adsorption tower I4 and adsorption tower II6 are connected with exhaust unit 8 respectively, and the air return ports at the bottom of adsorption tower I4 and adsorption tower II6 are connected with vacuum pump 3 respectively, and the air The pipelines between compressor I2 and adsorption tower I4 and adsorption tower II6 are respectively provid...

Embodiment 2

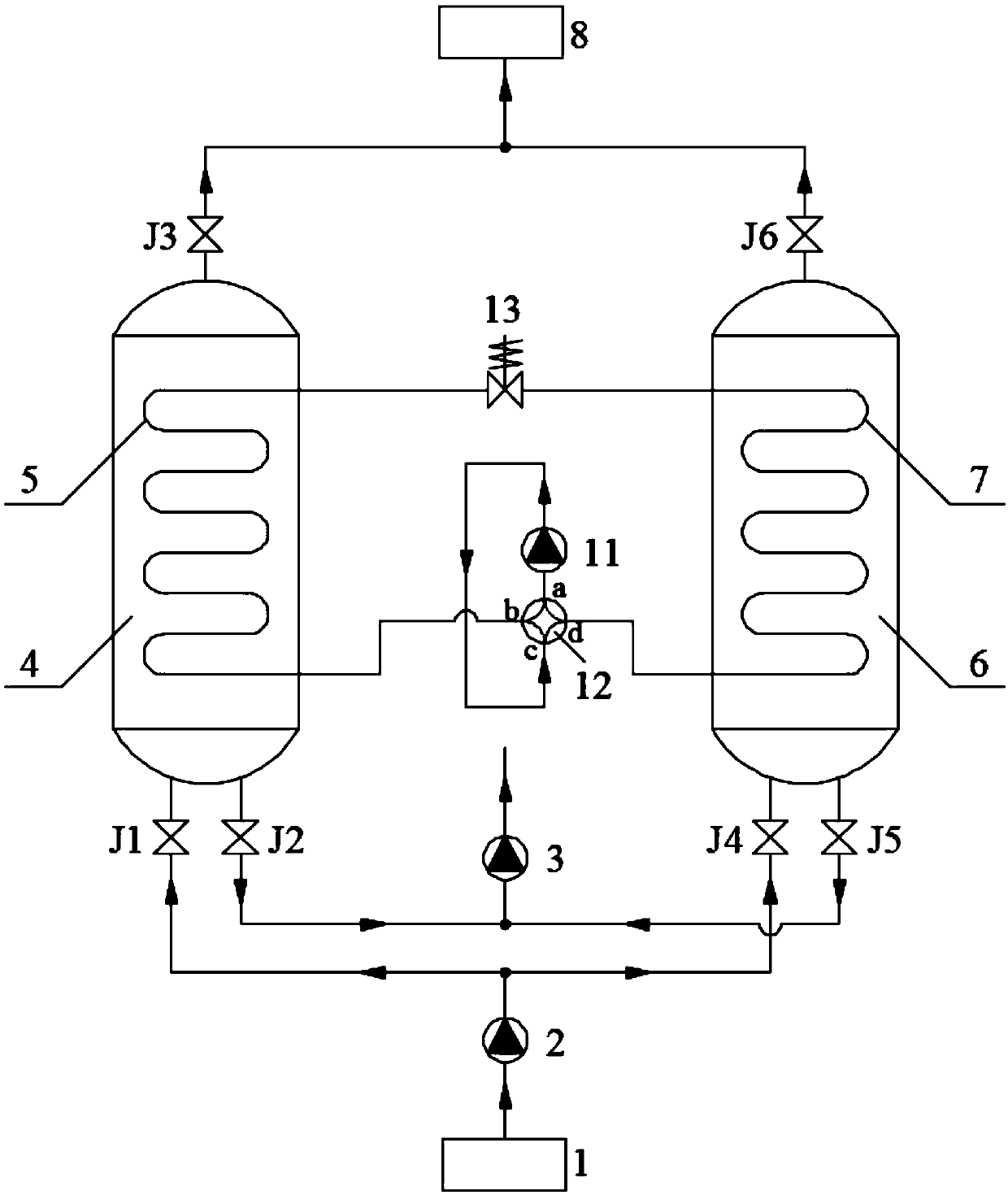

[0029] Such as figure 2 As shown, a temperature-pressure coordinated gas adsorption separation purification system includes an air intake unit 1, an exhaust unit 8, an adsorption separation unit and a temperature control unit,

[0030]Described adsorption separation unit comprises air compressor I2, vacuum pump 3, adsorption tower I4, adsorption tower II6, and the inlet end of air compressor I2 is communicated with inlet unit 1, and the exhaust end of air compressor I2 is connected with adsorption tower I4 respectively. , the air inlet at the bottom of the adsorption tower II6 is connected, the air outlets at the top of the adsorption tower I4 and the adsorption tower II6 are connected with the exhaust unit 8 respectively, the air return ports at the bottom of the adsorption tower I4 and the adsorption tower II6 are connected with the vacuum pump 3 respectively, and the air compressor The pipelines between I2 and adsorption tower I4 and adsorption tower II6 are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com