Injection type rotational flow continuous separator

A separator and ejector technology, which is used in cyclone devices, centrifugal separation water/sewage treatment, and devices whose axial directions of cyclone can be reversed. large problems, to achieve the effects of good mobility, broadening the application base, and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

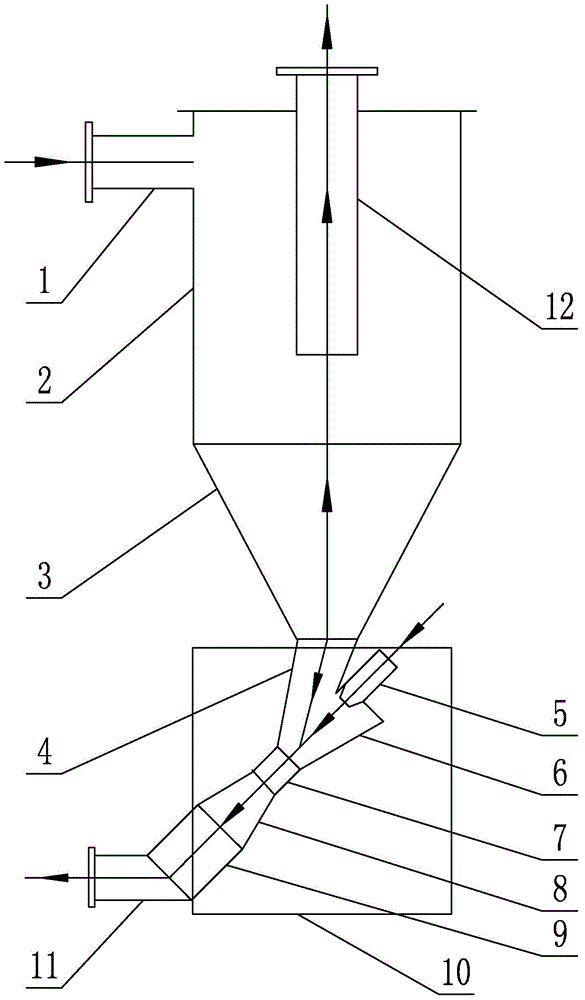

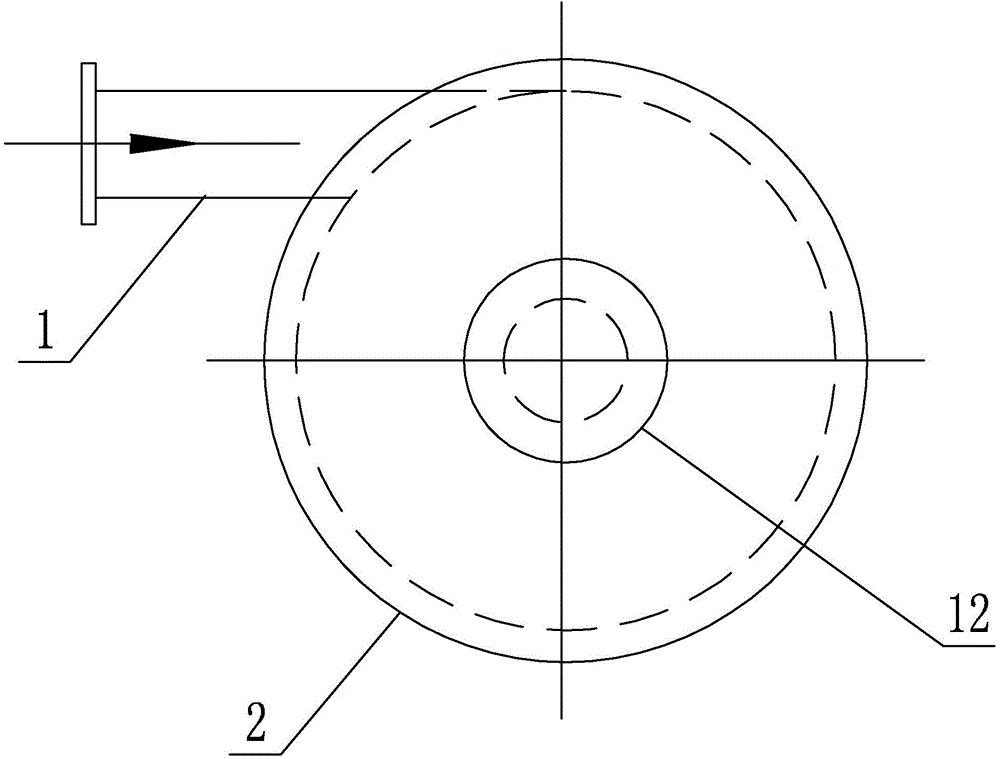

[0019] Specific implementation mode one: as Figure 1~2 As shown, the injection type cyclone continuous separator of the present embodiment comprises a sewage inlet pipe 1, a cylinder 2, a conical cylinder 3, a sewage outlet pipe 11 and an overflow pipe 12, and the outer diameter of the large end of the conical cylinder 3 is the same as that of the cylinder. The outer diameters of 2 are set equal, the lower end of the cylinder 2 communicates with the large end of the conical cylinder 3, the sewage inlet pipe 1 is arranged tangentially on the outer wall of the cylinder 2, and the sewage inlet pipe 1 communicates with the upper part of the cylinder 2, The overflow pipe 12 is vertically arranged on the axis of the cylinder 2; the separator also includes an ejector return device 10, which includes a blowdown pipe 4, a nozzle 5, a mixing chamber 6, a throat 7, a diffuser Pipe 8 and water mixing outlet pipe 9, mixing chamber 6, throat 7, diffuser pipe 8 and water mixing outlet pipe ...

specific Embodiment approach 2

[0020] Specific implementation mode two: as figure 1 As shown, the nozzle 5 and the mixing chamber 6 are arranged coaxially in this embodiment. Such a design makes it easy for the liquid sprayed from the nozzle 5 to smoothly inject the sewage containing more dirt and debris discharged from the sewage pipe 4 into the throat 7, so as to avoid dead ends and blockage of sewage discharge, and at the same time, it also helps to reduce sewage passing through the throat 7. part of the energy consumption. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: as figure 1 As shown, the cylinder 2 and the conical cylinder 3 are integrally made in this embodiment.

[0022] With such a design, the manufacturing cost is low, and at the same time, the stability of the cyclone continuous separator can be increased. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0023] Specific implementation mode four: as figure 1 As shown, the angle formed between the axis of the sewage outlet pipe 11 and the axis of the mixed water outlet pipe 9 in this embodiment is 110-160°. Such design is to facilitate the outflow of sewage and dirt and avoid blockage caused by straight elbows or near-straight elbows. Other components and connections are the same as those in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com