Horizontal spiral settling centrifugal separation device of biological enzyme extracting solutions

A horizontal spiral and separation device technology, applied in the field of machinery, can solve the problems of failure to achieve separation and use effects, poor clarity of the separation liquid, waste of time, etc., achieve good continuous separation effect, smooth slag discharge, and improve separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

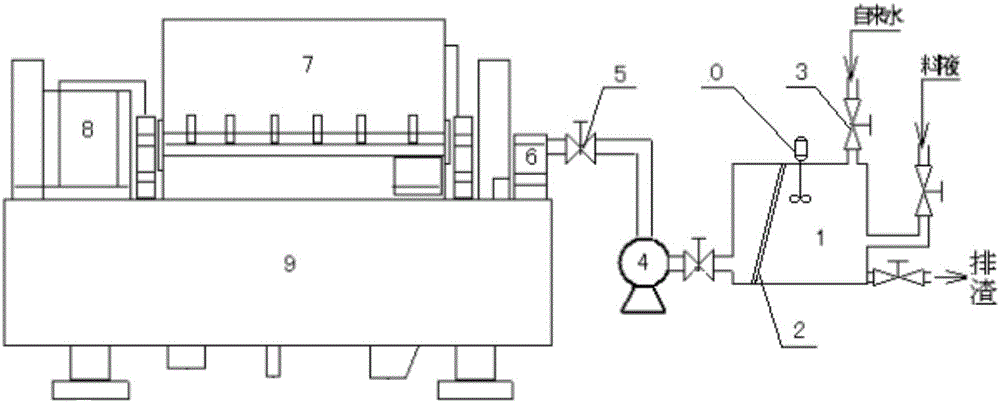

Embodiment 1

[0025] A horizontal spiral sedimentation centrifuge separation device for biological enzyme extract, which includes a flow control valve 3, a throttle valve 5, a screw pump 4 and a horizontal spiral sedimentation centrifuge 9, and is arranged before the horizontal spiral sedimentation centrifuge 9 Regulating liquid tank 1; described regulating liquid tank 1 is provided with material inlet, water inlet, agitator, filter screen 2, slag discharge port and discharge port; described feeding port is located at the front section of regulating liquid tank 1; The discharge port is located at the lower part of the regulating liquid tank; the water inlet is located above the regulating liquid tank 1 and connected to the water inlet flow control valve 3; the slag discharge port is located at the regulating liquid tank 1 the bottom of the bottom; the agitator is located on one side of the filter screen 2 feed port; the filter screen 2 is set to be inclined to the discharge port, and the fil...

Embodiment 2

[0034] A horizontal spiral sedimentation centrifuge separation device for biological enzyme extract, which includes a flow control valve 3, a throttle valve 5, a screw pump 4 and a horizontal spiral sedimentation centrifuge 9, and is arranged before the horizontal spiral sedimentation centrifuge 9 Regulating liquid tank 1; described regulating liquid tank 1 is provided with material inlet, water inlet, agitator, filter screen 2, slag discharge port and discharge port; described feeding port is located at the front section of regulating liquid tank 1; The discharge port is located at the lower part of the regulating liquid tank; the water inlet is located above the regulating liquid tank 1 and connected to the water inlet flow control valve 3; the slag discharge port is located at the regulating liquid tank 1 the bottom of the bottom; the agitator is located on one side of the filter screen 2 feed port; the filter screen 2 is set to be inclined to the discharge port, and the fil...

Embodiment 3

[0043]A horizontal spiral sedimentation centrifuge separation device for biological enzyme extract, which includes a flow control valve 3, a throttle valve 5, a screw pump 4 and a horizontal spiral sedimentation centrifuge 9, and is arranged before the horizontal spiral sedimentation centrifuge 9 Regulating liquid tank 1; described regulating liquid tank 1 is provided with material inlet, water inlet, agitator, filter screen 2, slag discharge port and discharge port; described feeding port is located at the front section of regulating liquid tank 1; The discharge port is located at the lower part of the regulating liquid tank; the water inlet is located above the regulating liquid tank 1 and connected to the water inlet flow control valve 3; the slag discharge port is located at the regulating liquid tank 1 the bottom of the bottom; the agitator is located on one side of the filter screen 2 feed port; the filter screen 2 is set to be inclined to the discharge port, and the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com