Egg white separator

A separator and egg white technology, applied in the field of separators, can solve the troublesome, time-consuming and labor-intensive problems of continuous large-scale separation of egg whites, egg whites and egg yolks, and achieve the effects of simple structure, simple and easy separation method, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

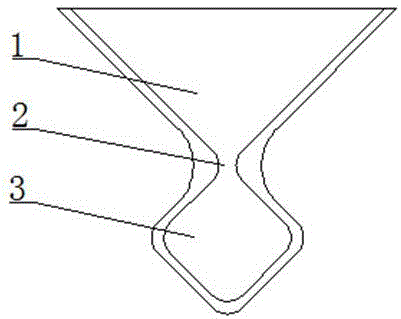

[0038] Such as figure 1 As shown, the egg white separator of the present invention includes a first passage 1 and a second passage 3 arranged overlappingly, the first passage 1 communicates with the second passage 3 through the gap 2, and the egg white in the first passage 1 is passed through by gravity. The slot 2 enters the second channel 3 . The separation of egg whites is realized through the setting of the gap 2, so that the egg yolks remain in the first channel 1. This structure can realize the continuous separation of egg whites, and multiple eggs can be placed on the first channel 1 to improve the separation efficiency. In addition, tilting the After the device is installed, flow can be realized to complete the effect of continuous separation. Its structure is simple, easy to use, and separation can be realized quickly to improve the separation effect.

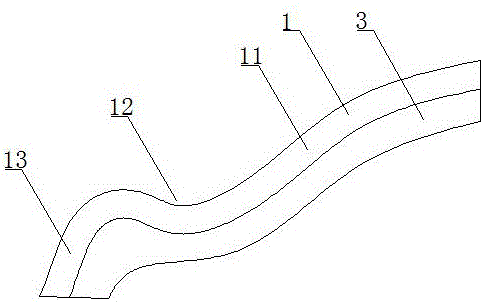

[0039]The first channel 1 includes an acceleration part 11 , a centrifugal part 12 , and an output part 13 in seque...

Embodiment 2

[0045] Based on the egg white separator of Example 1, the separation device of the egg white separator includes a hopper, a vertically arranged spiral channel connected to the hopper, an egg white separator connected to the outlet of the lower part of the spiral channel, and an egg white separator located at the outlet of the egg white separator. The transfer tray at the transfer tray and the collection bucket under the transfer tray;

[0046] The transfer tray is divided into a first transfer tray and a second transfer tray, the first transfer tray communicates with the first passage 1, and the second transfer tray communicates with the second passage 3;

[0047] The collection barrel includes a first collection barrel, a second collection barrel, and a third collection barrel, the first collection barrel corresponds to the output port of the first transfer tray, and the second collection barrel corresponds to the output port of the second transfer tray;

[0048] The spiral c...

Embodiment 3

[0053] Based on the egg white separator of embodiment 1 or 2, a braided layer with a thickness of 0.3-0.5 mm and an anti-rust coating with a thickness of 0.1-0.15 mm are sequentially provided on the inner surfaces of the first channel 1 and the second channel 3 to prevent rust The coating consists of the following materials by weight: 2 parts of carbon, 1 part of silicon, 0.7 parts of manganese, 0.8 parts of nickel, 1.3 parts of chromium, 1.4 parts of molybdenum, 12 parts of copper, 3 parts of boron, 13 parts of phosphorus, 20 parts of nitrogen, 2 parts tungsten, 70 parts of iron, 8 parts of silver; the weaving layer is composed of the following materials by weight: 7 parts of silver wire, 15 parts of stainless steel fiber, 30 parts of iron wire, 7 parts of bamboo fiber, 2 parts of ceramic fiber, 4 parts of flame retardant fiber. The rust-removing coating with this composition has uniform coating, good gloss, and good anti-rust effect. Its surface is uniform and smooth. The si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com