Dry discharging device for tailings of circular pipe through multiple force fields and use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

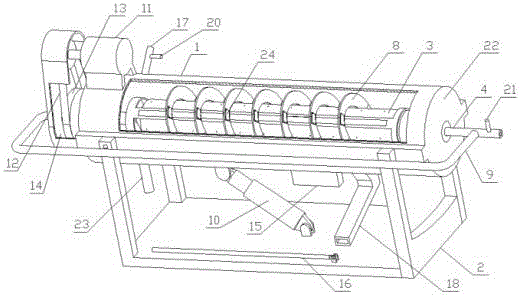

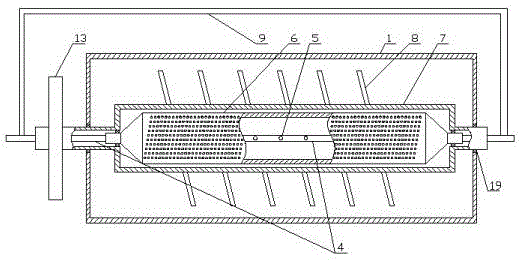

[0024] Example 1. A circular tube multi-force field tailings dry discharge device, which is composed of Figure 1-2 As shown, it includes cylinder body 1, and cylinder body 1 is provided with spiral separating mechanism 3, and one end of spiral separating mechanism 3 is connected with driving mechanism; Described spiral separating mechanism 3 comprises suction filter pipe 4, is distributed on the suction filter pipe 4 The air hole 5 and the suction filter pipe 4 are sequentially provided with a filter screen 6 and a filter cartridge frame 7 radially outward, and spiral blades 8 are also distributed on the filter cartridge frame 7 . Such as figure 2 As shown, the cylinder body 1 and the filter frame 7 are connected by bearings 19, and the filter frame 7 and the filter screen 6 are also connected by bearings 19.

[0025] The two ends of the aforementioned suction filter pipe 4 are also connected through a connecting pipe 9 . Through this structure, when the vacuum pump is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com