Multi-baffle type oil-and-water separator

An oil-water separator and baffle-type technology, which is applied in the direction of liquid separation, separation method, foam dispersion/prevention, etc., can solve the problems of poor separation effect of oil-water separator, avoid emulsification, suppress air bubbles and turbulent flow, and separate good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

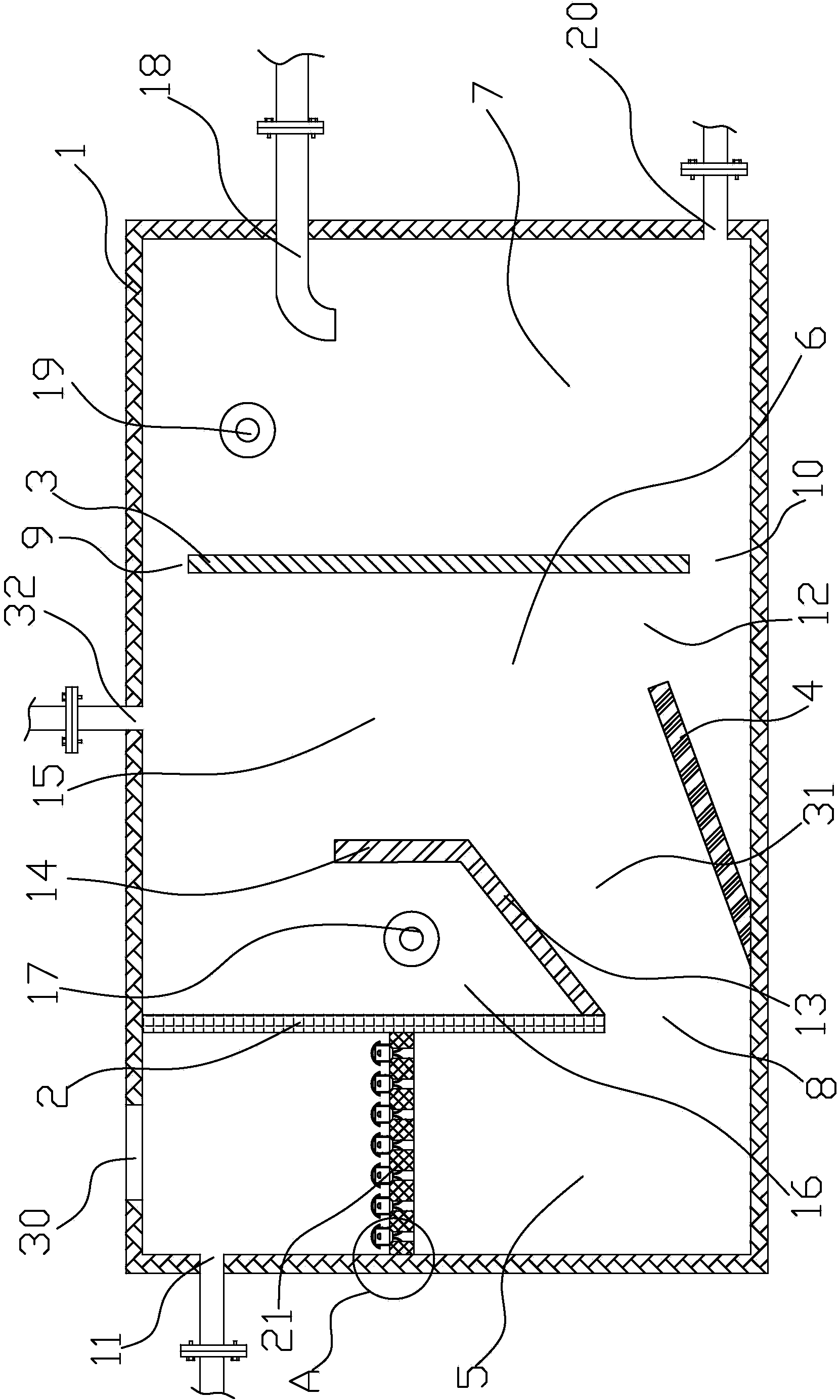

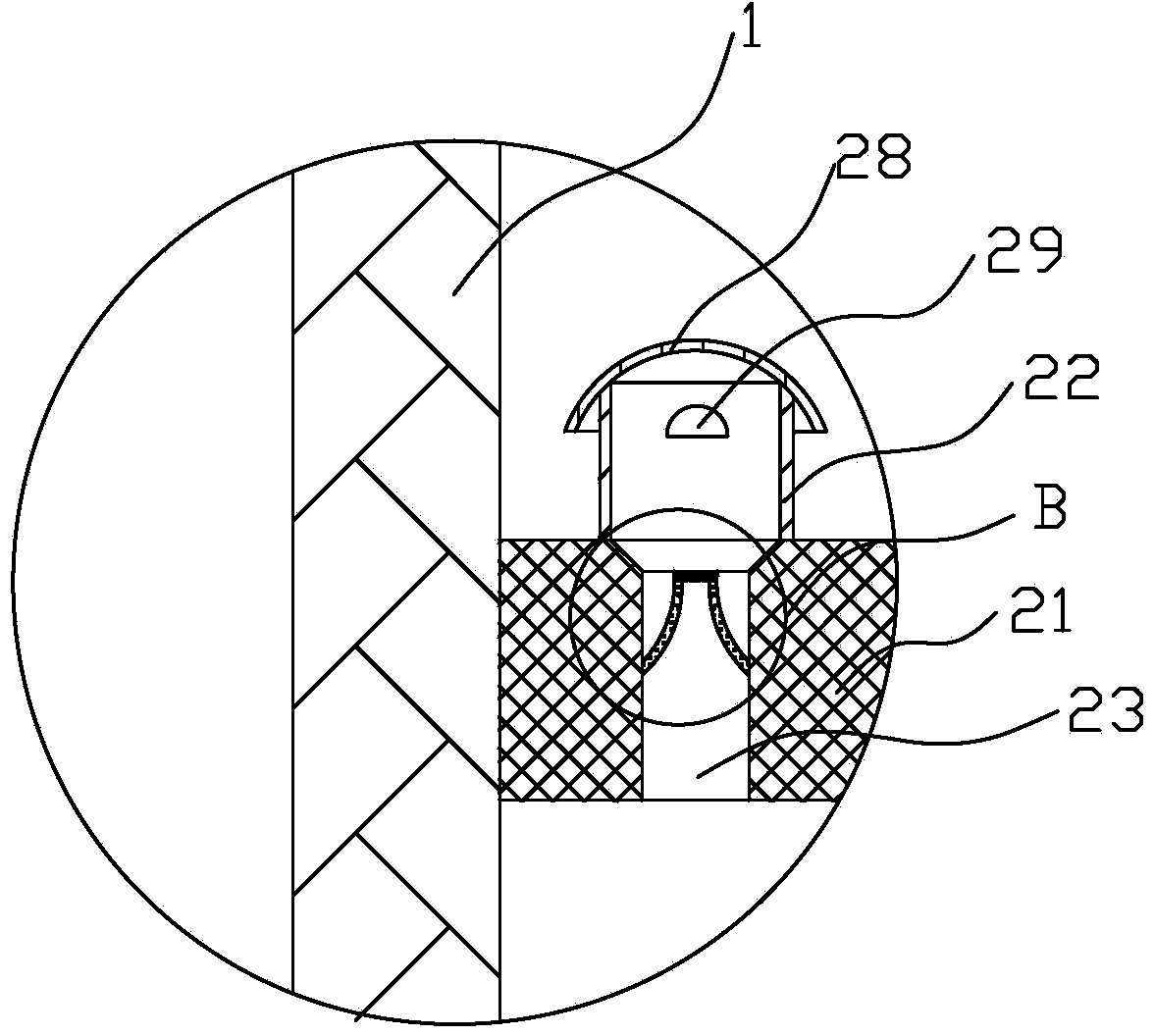

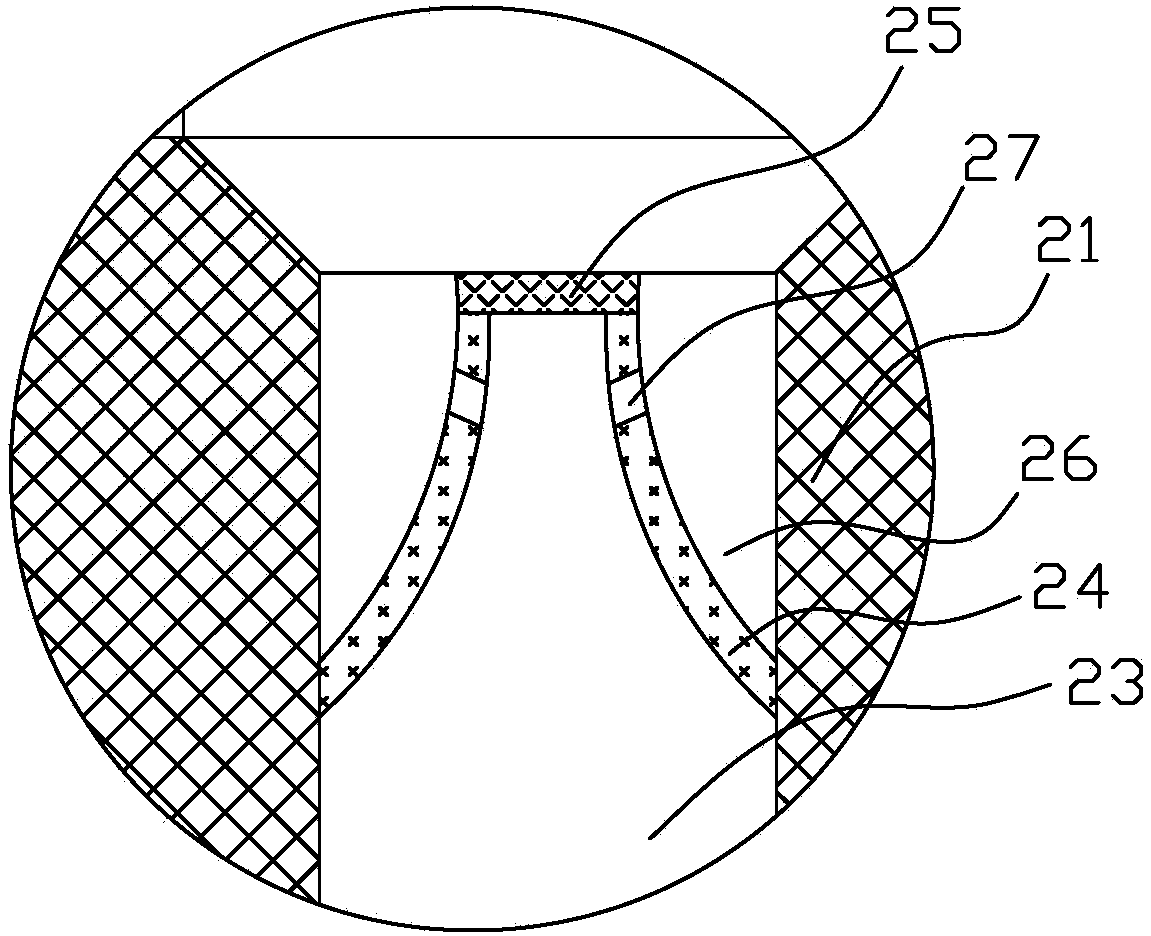

[0023] Such as figure 1 The shown multi-baffle type oil-water separator includes a hollow and cuboid structure tank body 1, a first baffle plate 2 fixed in the tank body, a second baffle plate 3 and an inclined baffle plate 4, the first baffle plate, The second baffle divides the internal space of the tank body into a slow-flow defoaming zone 5, a sedimentation separation zone 6 and a water collection zone 7, and an observation window 30 is arranged on the tank body at the top of the slow-flow defoaming zone, wherein the first baffle plate There is a gap between the bottom surface of the tank and the second baffle and the top and bottom of the tank. The gap between the first baffle and the bottom of the tank forms a material passage port 8, and the second baffle and the top of the tank The gap between the surfaces forms the air pressure balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com