Tubular continuous liquid-liquid extraction device and operation method thereof

An operation method and technology of an extraction device, which are applied in the field of liquid-liquid extraction equipment, can solve the problems that the production process cannot be well satisfied, cannot be operated for a long period of time, and the equipment occupies a large area. The effect of long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

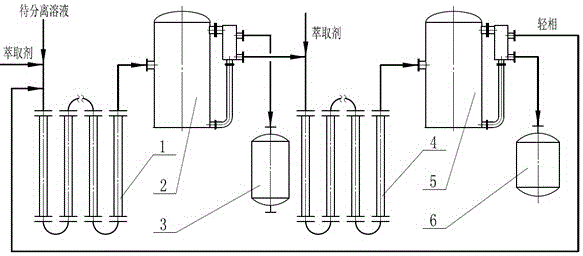

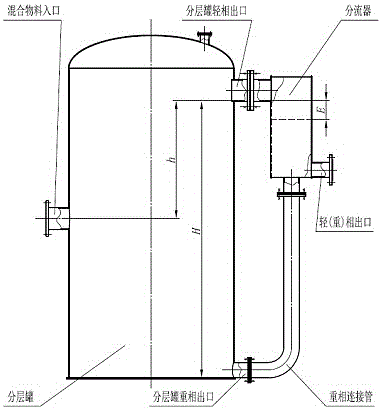

[0027] The extraction phase after the mixed liquid to be separated is extracted is the light phase. A tubular continuous liquid-liquid extraction device, the first-stage tubular extractor (1) and the second-stage tubular extractor (4) are composed of straight pipes and elbows with chemical fillers inside; the first-stage extractor used The structure of the phase and raffinate phase separator (2) and the secondary extract phase and raffinate phase separator (5) is as follows image 3 ; Primary tubular extractor (1), primary extract phase and raffinate phase separator (2), extract phase storage tank (3), secondary tubular extractor (4), secondary extract phase and raffinate The layout of phase separator (5), raffinate phase storage tank (6) and connecting pipelines between equipment is as follows: figure 1 .

[0028] The mixed liquid to be separated and the extractant enter the first-stage tubular extractor (1) while flowing and mixing for the first-stage extraction, and the m...

Embodiment 2

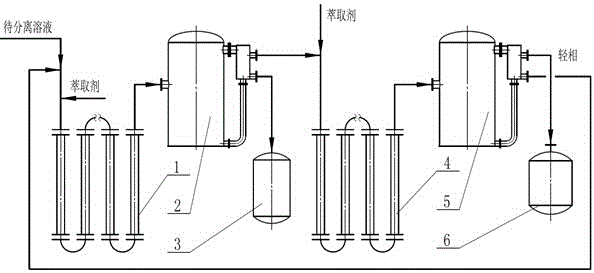

[0030] Embodiment 2 is basically the same as Embodiment 1, except that after the mixed liquid to be separated is subjected to extraction operation, the extraction phase is a heavy phase; the equipment used and the arrangement of connecting pipelines between equipment are as follows: figure 2 .

[0031] The mixed solution to be separated and the extractant enter the first-stage tubular extractor (1) while flowing, mixing, and perform primary extraction; the mixed solution exiting the first-stage tubular extractor (1) enters the first-stage extraction phase and raffinate The phase separator (2) is used for separation, and the separated raffinate phase (light phase) flows out from the light phase outlet of the splitter of the primary extraction phase and the raffinate phase separator (2), and another stream of extractant enters the secondary pipe The extractor (4) performs secondary extraction while flowing, mixing, and extraction; the extraction phase (heavy phase) separated by...

Embodiment 3

[0033] Example 3 is basically the same as Example 1, except that the first-stage tubular extractor (1) and the second-stage tubular extractor (4) used are composed of a commercially available static mixer and an elbow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com