Analogue mobile bed chromatic reactor

A technology for simulating moving beds and reactors, applied in the field of simulated moving bed chromatography reactors, can solve the problems of large amount of stationary phase and mobile phase in intermittent chromatography, difficult popularization and application of chromatography reactor technology, and low concentration of separated products, etc. Speed, improve separation efficiency, improve the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

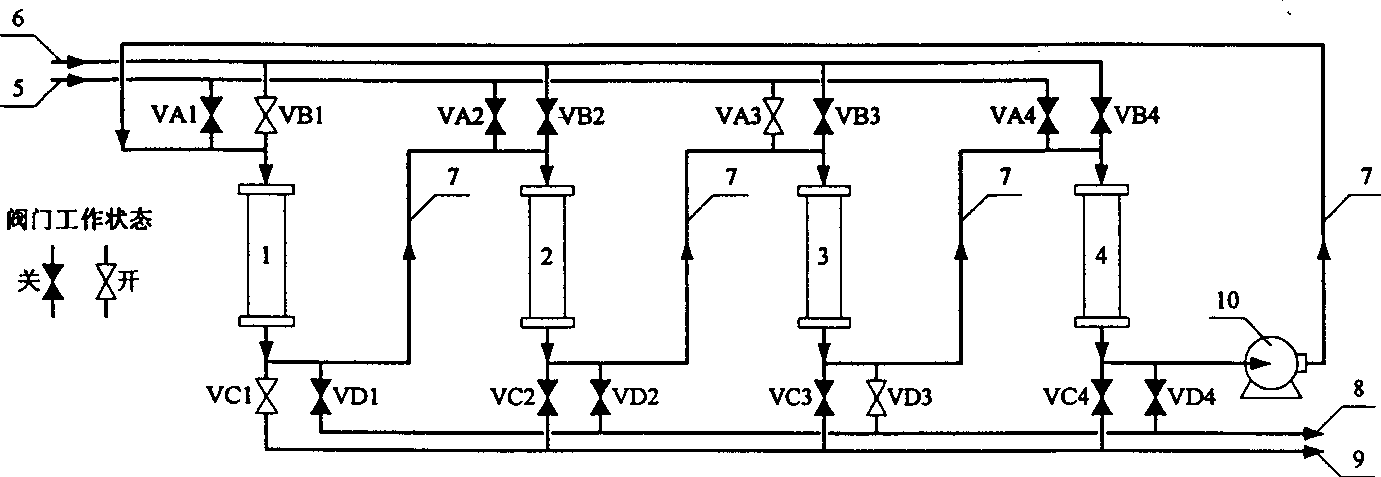

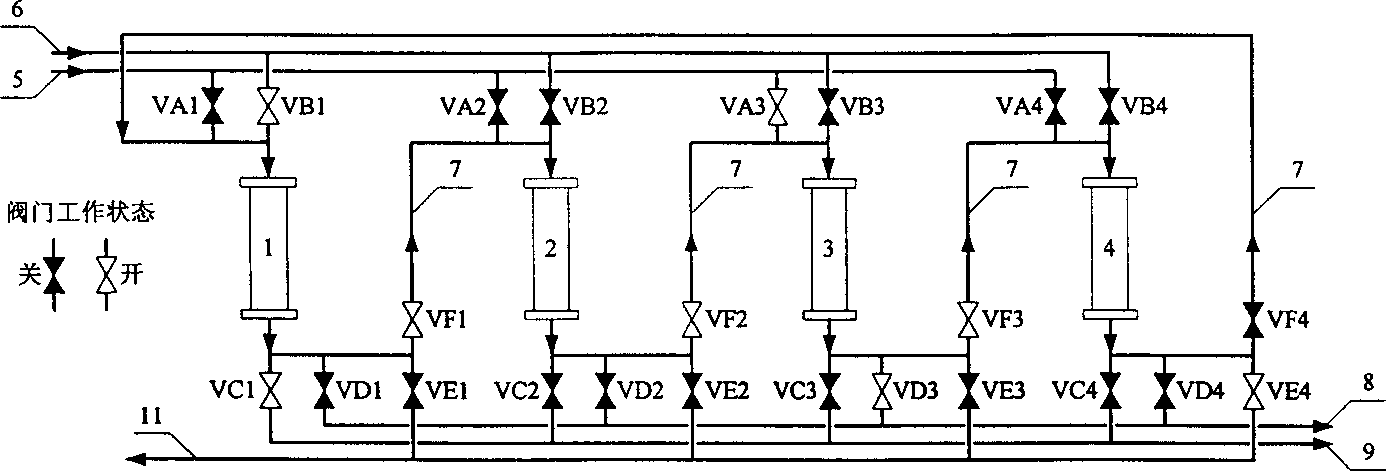

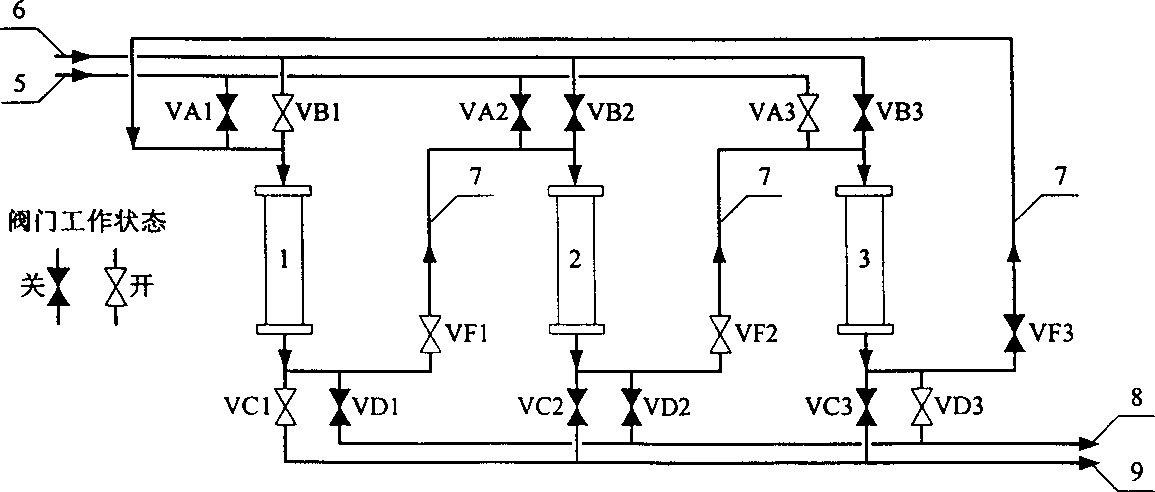

[0018] like figure 1 The simulated moving bed chromatographic reactor of the closed-loop structure shown, it comprises four packed columns 1,2,3,4, is connected by the outlet end of the first packed column 1 and the inlet port of the second packed column 2, the first The outlet end of the two packed columns 2 is connected to the inlet end of the third packed column 3, the outlet end of the third packed column 3 is connected to the inlet end of the fourth packed column 4, and the outlet end of the fourth packed column 4 The inlet port of the first packed column 1 is connected through the circulating pump 10 and the connecting pipeline 7; the inlet port of each packed column 1, 2, 3, 4 passes through the respective on-off valves VA1, VA2, VA3, VA4 and They are respectively connected to the raw material liquid inlet pipeline 5 for inputting the reactant and the eluent inlet pipeline 6 for inputting the eluent through respective on-off valves VB1, VB2, VB3, VB4; each packed column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com