Continuous tray separation device, equipment and method

A separation device and separation equipment technology, used in storage devices, transportation and packaging, destacking of objects, etc., can solve problems such as low efficiency, difficult separation, and inability to achieve full automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

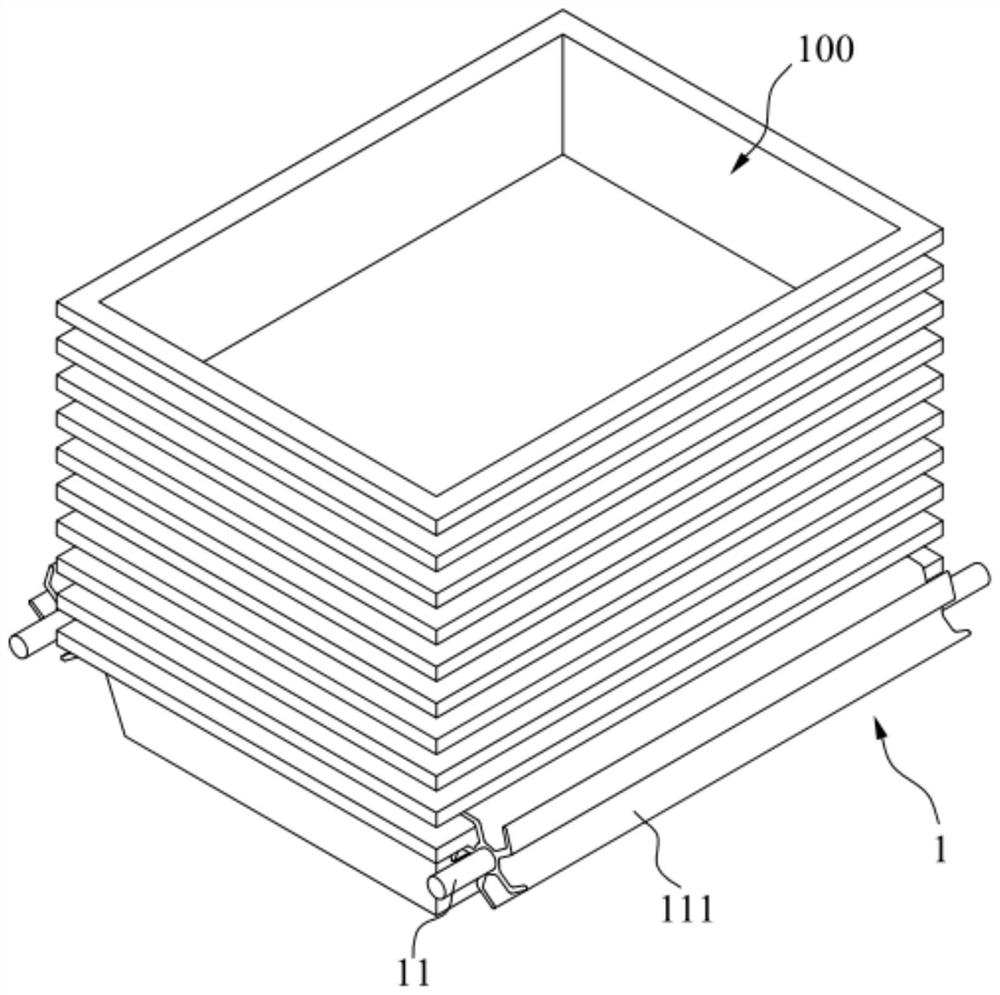

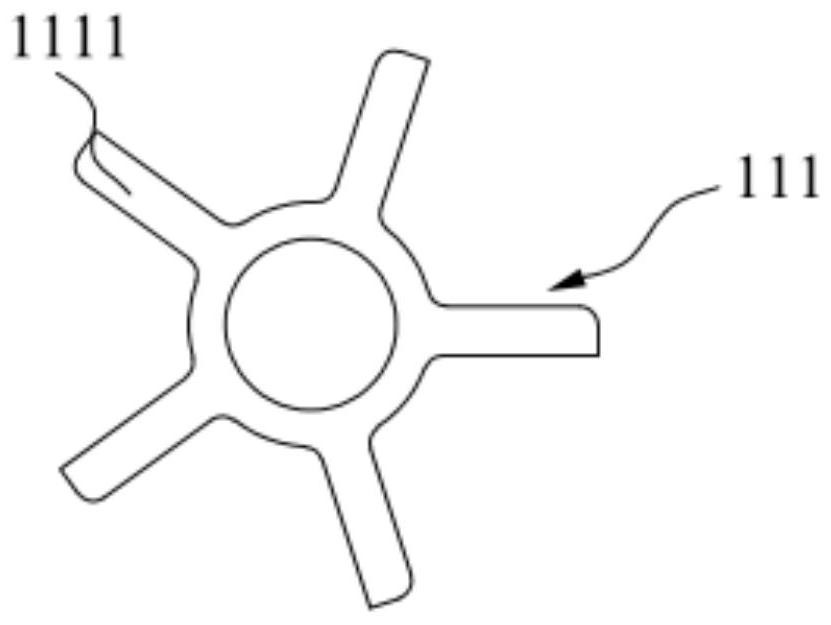

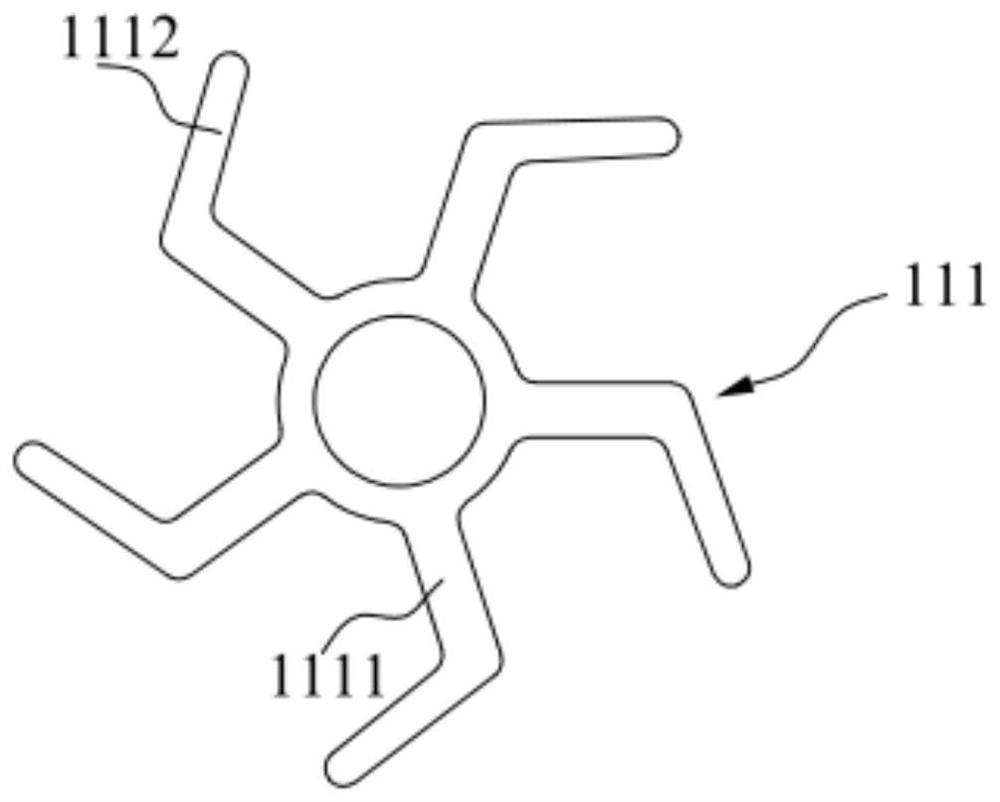

[0039] Such as Figure 1-Figure 9 As shown, the present invention provides a continuous separation device for trays, including a separation mechanism 1 and a control module. The separation mechanism 1 includes two separation rollers 11 rotatably mounted on the frame, and the two separation rollers 11 are symmetrically arranged on both sides of the tray 100. On the other hand, the outer periphery of the separating roller 11 is provided with a plurality of separating assemblies 111 extending axially along the separating roller 11, and the plurality of separating assemblies 111 are evenly distributed along the outer periphery of the separating roller 11; the control module can control the two separating rollers 11 in the axial direction The center rotates in reverse synchronously. In this embodiment, five sets of separation assemblies 111 are evenly distributed on the outer circumference of the separation rollers 11, and the control module controls the separation rollers 11 on bo...

Embodiment 2

[0049] Disclosed in this embodiment is a method for continuous separation of pallets, such as Figure 8 and Figure 9 As shown, the above-mentioned pallet continuous separation equipment is used, comprising the following steps:

[0050] S1: The propulsion device is activated, pushing the stack of trays onto the separation assembly 111 of the two separation rollers 11;

[0051] In this step, the control module controls the propulsion device to push the stacked trays onto the two separation rollers 11 , so that the bottommost tray 100 rests on the separation assemblies 111 on both sides.

[0052] S2: The tray continuous separation device starts, the two separation rollers 11 rotate in reverse synchronously, and the separation component 111 separates the bottom tray 100;

[0053] In this step, when the stack of trays in S1 is put away, the control module controls the separation rollers 11 on both sides of the tray 100 (or the separation roller 11 on one side) to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com