Method for preparing peptide-enriched product with high content of glutamine-bound peptide

A high-glutamine, peptide-binding technology, applied in the fields of medicine, food, and agricultural product processing, can solve the problems of high enzyme consumption, substrate waste, and product separation, and achieve the effect of reducing free amino acid content and substrate inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

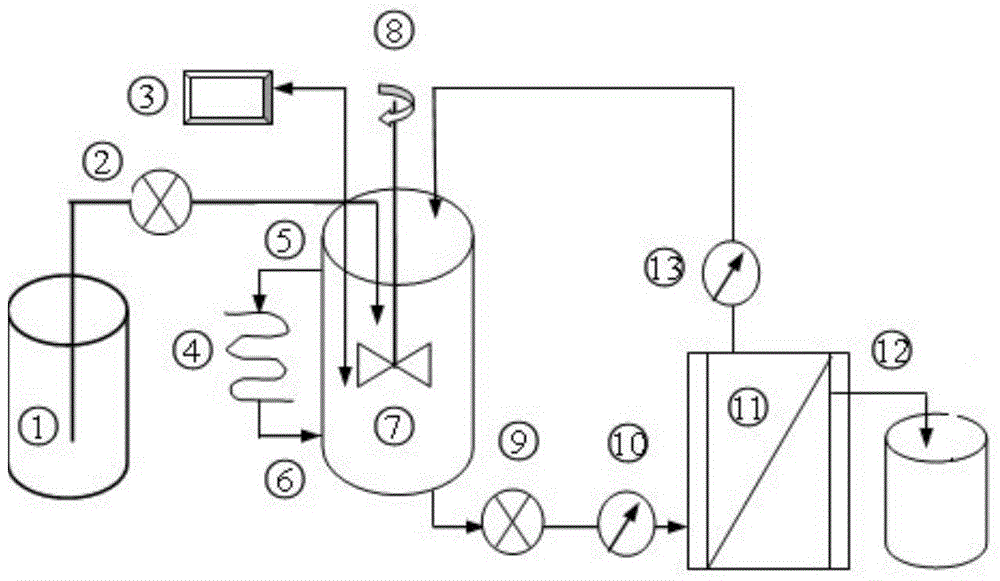

Method used

Image

Examples

Embodiment 1

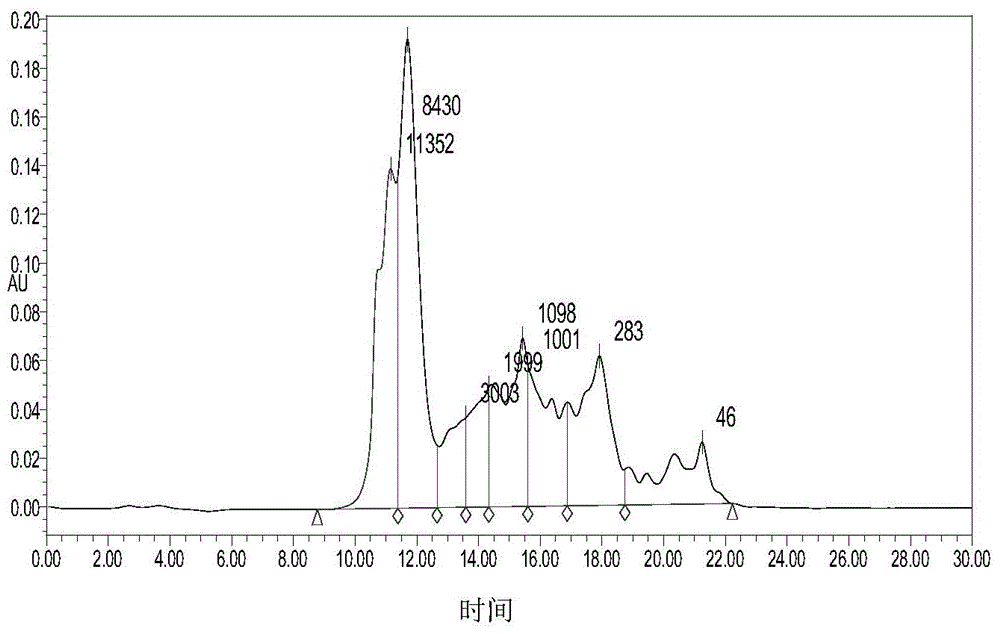

[0031] Water and wheat protein (gu Nguyen powder) are added to the mixing tank for slurry mixing, the temperature is 60° C., the pH is 10, the mass concentration of wheat protein is 50%, and the alkaline protease ( 40U / g wheat protein) and papain (40U / g wheat protein); after 3 hours of reaction, the wheat protein slurry was added to the enzyme reactor, the temperature was set at 80°C, the pH was 10, and the total activity of 80U / g wheat was added trypsin, trypsin, alkaline protease, neutral protease and compound flavor protease for enzymolysis of protein, and at the same time, the enzymolysis solution is continuously introduced into the vibrating membrane (ultrafiltration with a molecular cut-off of 10kDa) equipment from the bottom of the enzyme reactor, The small molecule target peptide is filtered out in time through the vibrating membrane device, and the macromolecular substrate and enzyme are returned to the enzyme reactor to continue the enzymatic hydrolysis reaction, impr...

Embodiment 2

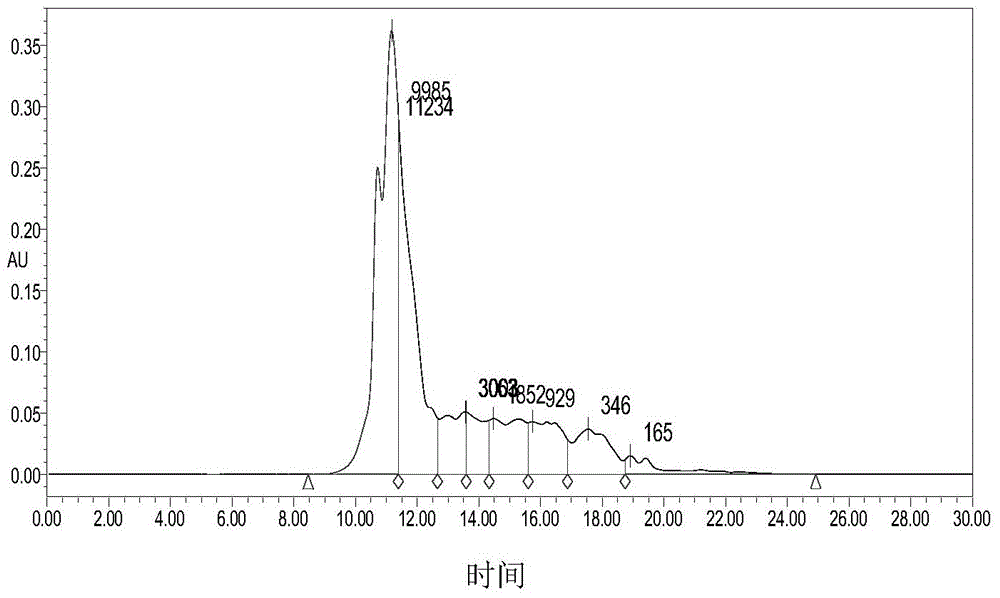

[0033]Add water and wheat protein (guruan powder) to the mixing tank for mixing, the temperature is 40°C, the pH is 4, the concentration of wheat protein is 50%, add 20U / g acid protease, and the wheat protein slurry is reacted for 1 hour Add it into the enzymolysis tank, set the temperature to 40°C and pH to 4, add 20U / g of acid protease, neutral protease and compound flavor protease for enzymolysis, and continuously introduce the vibrating membrane from the bottom of the tank (the molecular cut-off flow is 10kDa In the ultrafiltration) equipment, the small molecular target peptide is filtered out in time through the vibrating membrane equipment, and the macromolecular substrate and enzyme are returned to the enzyme reaction tank to continue the enzymatic hydrolysis reaction, improving the conversion rate of protein and the utilization rate of enzyme. The operating pressure of the vibrating membrane ultrafiltration membrane is 0.02Mpa, and the circulation flow rate is 20L / h. W...

Embodiment 3

[0035] Add water and wheat protein (gu Nguyen powder) to the mixing tank for mixing, the temperature is 50°C, the pH is 8, the concentration of wheat protein is 45%, add 50U / g of neutral protease and alkaline protease, and react 1 Hours later, the wheat protein slurry was added to the enzymolysis tank, the temperature was set at 60°C, the pH was 6, 40U / g of acid protease, neutral protease and compound flavor protease were added for enzymolysis, and the vibrating membrane was continuously introduced from the bottom of the enzyme reactor (Ultrafiltration with a molecular cutoff of 8kDa) equipment, the small molecule target peptide is filtered out in time through the vibrating membrane device, and the macromolecular substrate and enzyme are returned to the enzyme reaction tank to continue the enzymatic hydrolysis reaction, improving the conversion rate of protein and the activity of enzyme. utilization rate. The operating pressure of the vibrating membrane ultrafiltration membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com