Crushing and recycling device for construction waste

A recovery device and technology for construction waste, applied in solid separation, screening, grids, etc., can solve the problems of large manpower consumption and low screening efficiency, and achieve the effects of avoiding damage, ensuring comfort, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

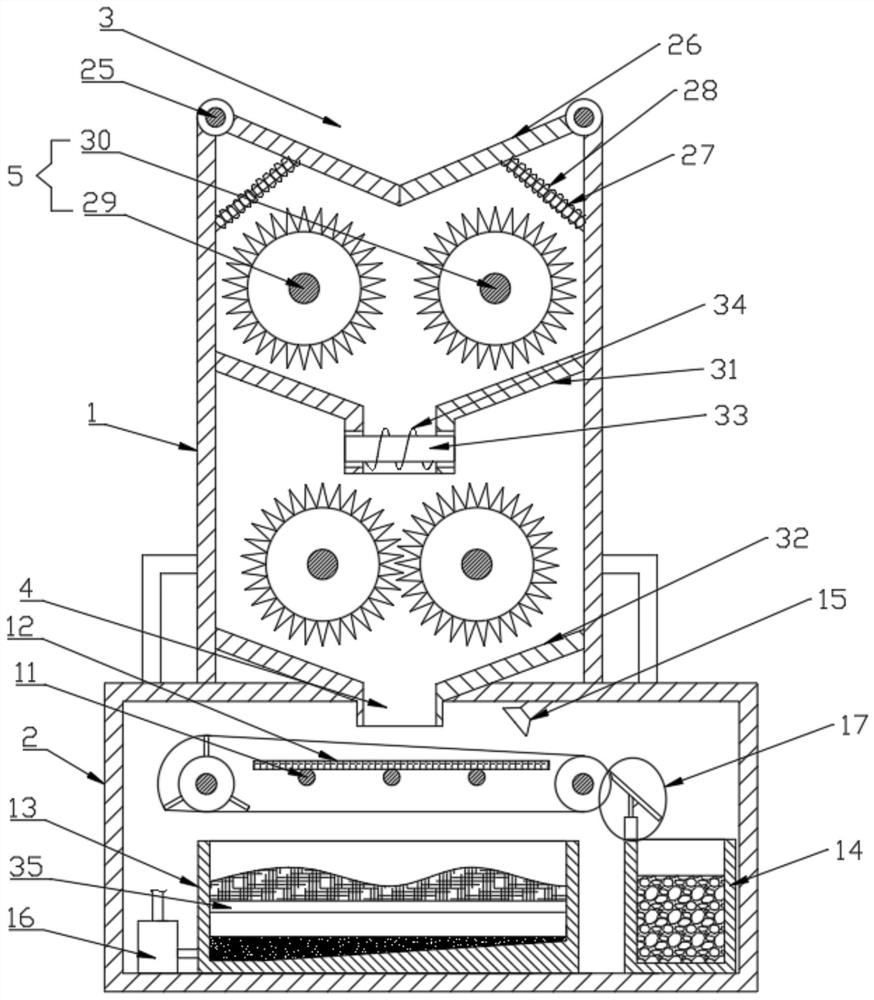

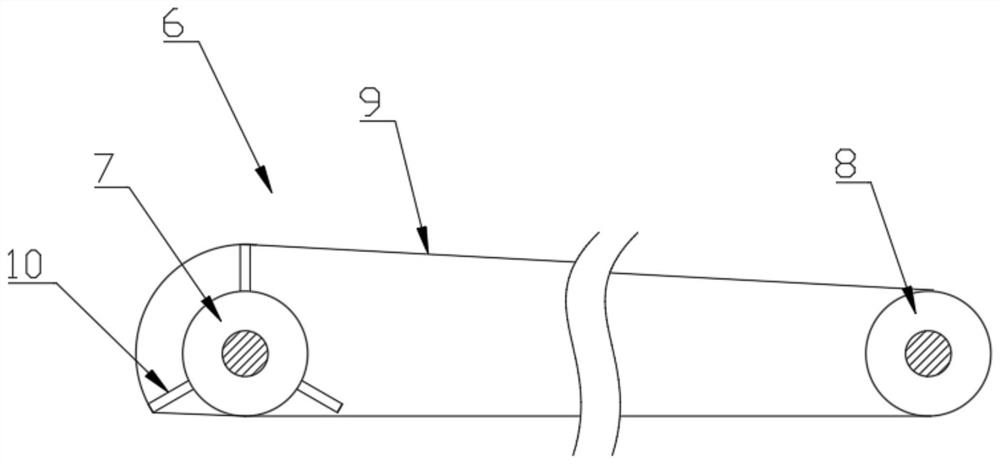

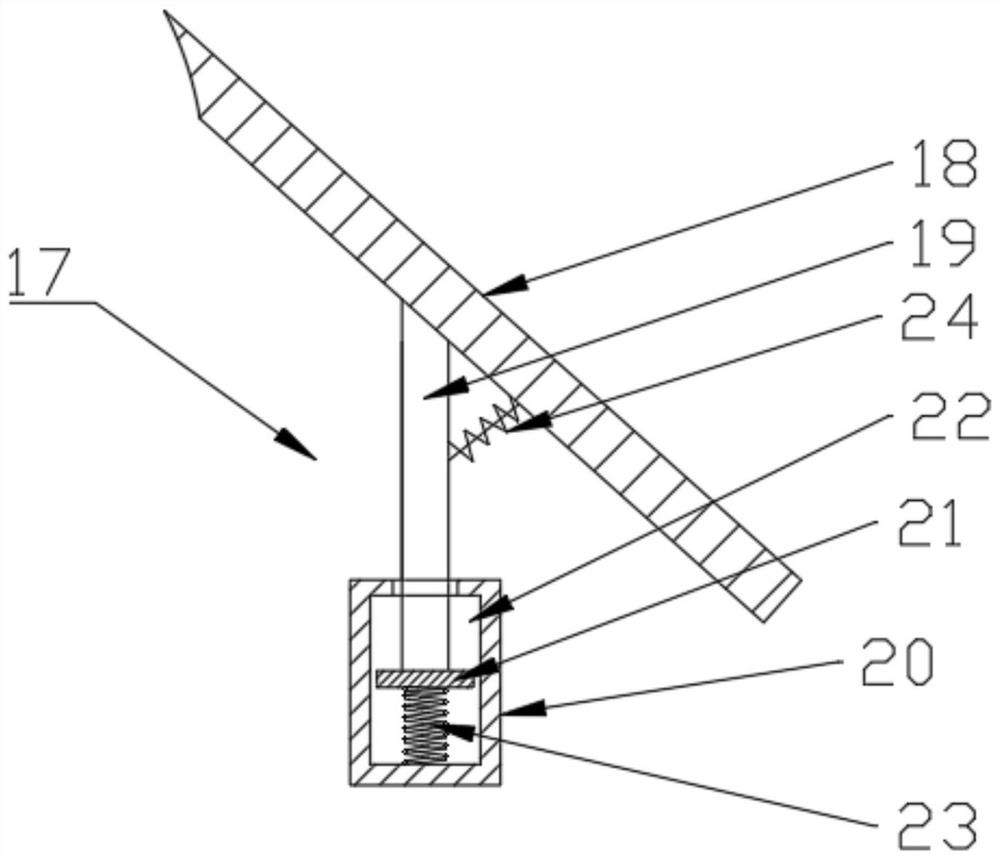

[0025] see Figure 1-5 , a crushing and recycling device for construction waste, comprising a crushing box 1 and a recycling box 2, the top and bottom of the crushing box 1 are respectively provided with a feed port 3 and a discharge port 4, and the crushing box 1 is arranged from top to bottom. A plurality of pulverizing mechanisms 5 are arranged, and the discharge port 4 is connected with the recovery box 2, and the lower end of the discharge port 4 in the recovery box 2 is provided with a conveying device 6, and the conveying device 6 includes a driving roller 7, a driven roller 8 and a conveyor belt 9, the conveyor belt 9 is supported between the driving roller 7 and the driven roller 8, and the conveyor belt 9 is provided with a screen hole, and the driving roller 7 and the driven roller 8 are all rotated with the recovery box 2 connected, and the driving roller 7 is provided with three driving teeth 10, and the three driving teeth 10 are distributed in an annular array o...

Embodiment 2

[0033] This embodiment has been improved on the basis of Embodiment 1, specifically:

[0034] The two side walls of the top of the crushing box 1 are symmetrically fixed with a rotating shaft 25, and a door 26 is hinged on the rotating shaft 25, and a telescopic rod 27 is arranged between the bottom surface of the door 26 and the side wall of the crushing box 1. , the telescopic rod 27 is covered with a third spring 28, by setting the door 26, when the construction waste is imported, under the gravity of the construction waste, the doors 26 on both sides are opened, so that the construction waste is introduced into the crushing box 1 Inside, after the construction waste enters the crushing box 1, under the force of the third spring 28, the bin door 26 is closed again, which not only avoids the overflow of dust when the construction waste is crushed, but also ensures the comfort of the surrounding environment. It avoids the splashing of fine particles of construction waste duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com