Method for preparing large-head atractylodes rhizome and sesquiterpene compound

A technology of sesquiterpene and compound, which is applied in the field of preparation of Atractylodes sesquiterpene compound by supercritical extraction coupling fractionation technology, which can solve problems such as complex process and removal of monoterpene compounds, achieve low temperature, maintain biological activity, and not easily Effects of Oxidation and Degradation Reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

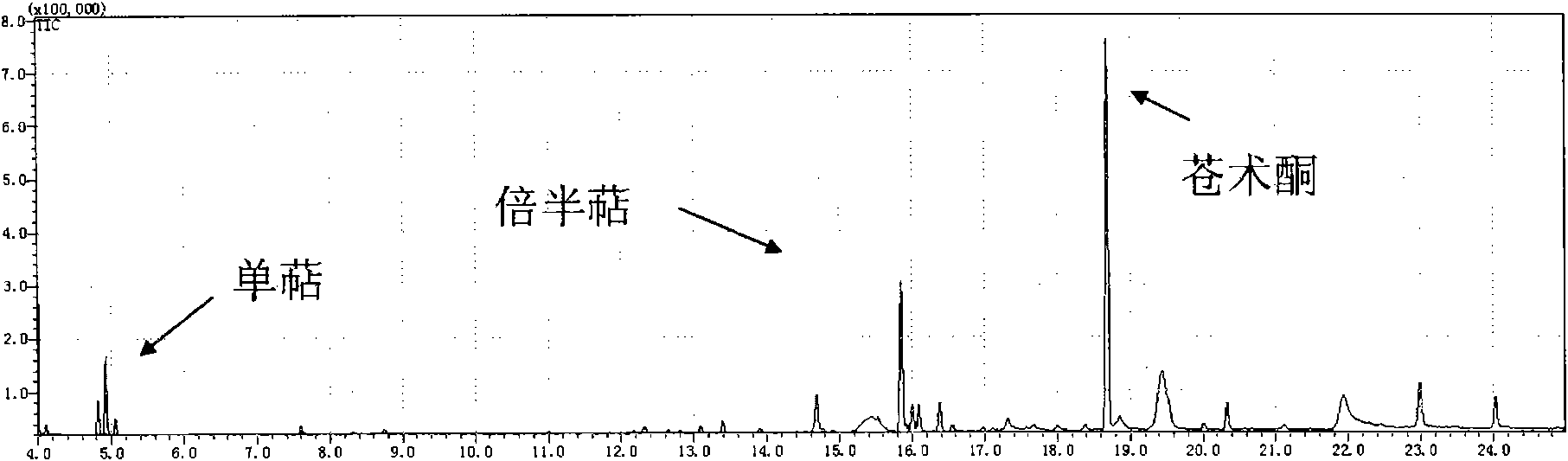

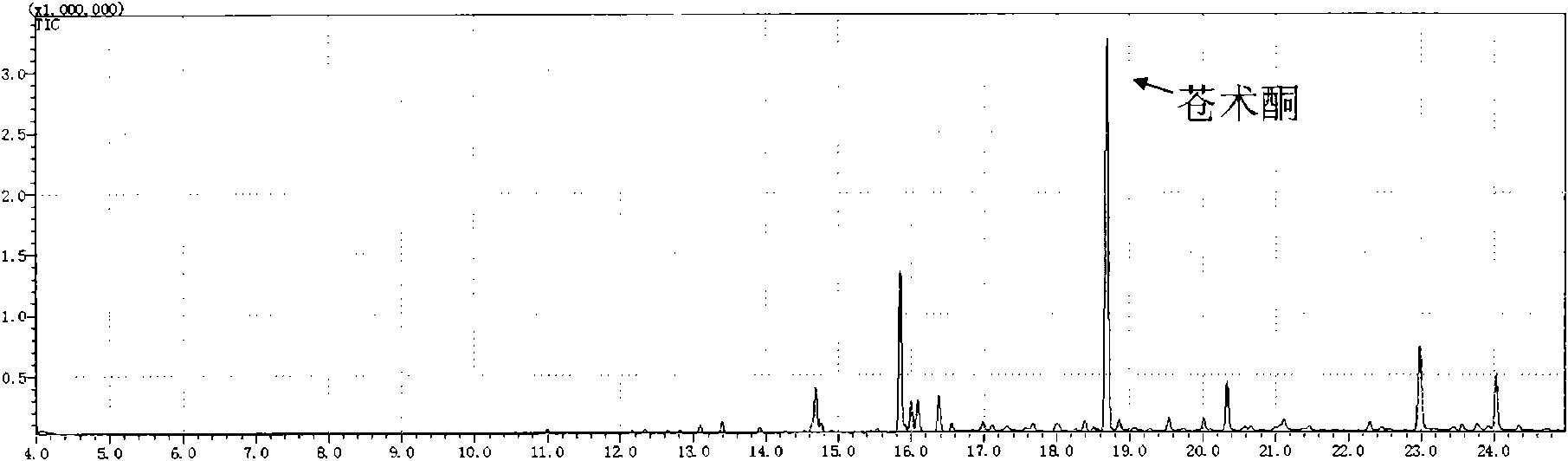

[0029] Example 1 Preparation of Deterpenes and Sesquiterpene Compounds of Atractylodes Rhizome Volatile Oil

[0030] 1. Extraction and fractionation process of Atractylodes macrocephala volatile oil

[0031] Atractylone reference substance, provided by Shenzhen Neptunus Biological Co., Ltd.

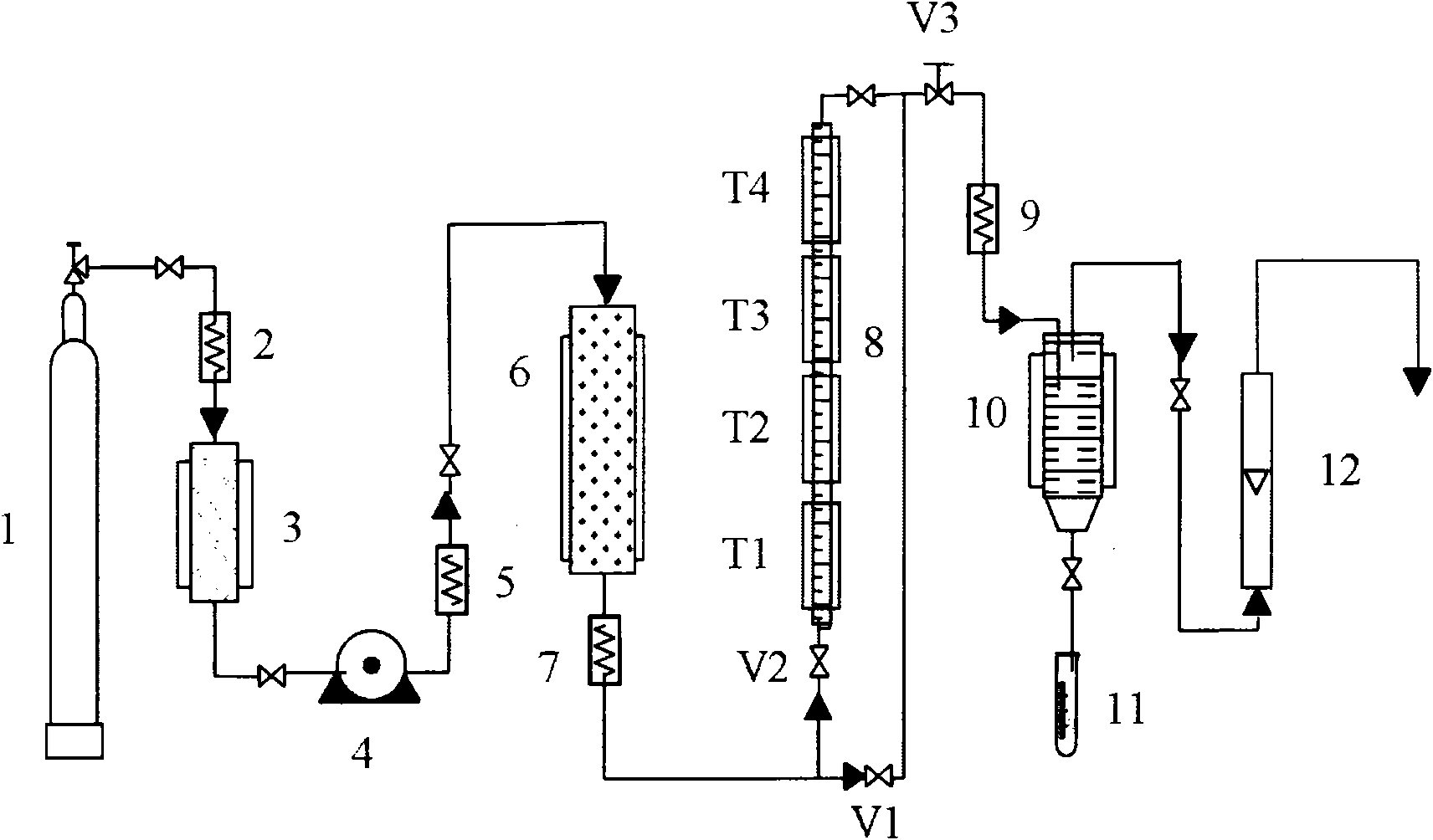

[0032] Experimental device: supercritical CO 2 The extraction and fractionation equipment is manufactured by Jiangsu Huaan Supercritical Company, and the device is made of CO 2 It is composed of supply system, extractor, fractionation column and separator. The volume of the extractor is 1L, the height of the fractionation column is 2m, and the inner diameter is 20mm. The column is filled with stainless steel foil and divided into four sections for temperature control. Valves V1 and V2 control the pipes connecting the extractor, fractionation column and separator, and valve V3 controls the pressure of the fractionation column. The entire system can withstand a maximum pressure of 35M...

Embodiment 2

[0042] The extraction of embodiment 2 Atractylodes macrocephala volatile oil

[0043] This example examines the extraction process of Atractylodes macrocephala volatile oil. Put 200g of Atractylodes macrocephala medicinal material into the liner of the extractor, and seal it. Open CO 2 Cylinder, CO 2 After the gas is cooled into a liquid by the cooler 3, it is pressurized by the high-pressure metering pump 4 and enters the extractor 6. After extracting the volatile oil under the extraction conditions of 25MPa and 308K, open the valve V1, close the valve V2, supercritical CO 2 The volatile oil is carried into the separator 10 for analysis at 5MPa and 323K. CO 2 The flow rate is controlled at 5L / min, and is emptied through the rotameter 12. The extracted volatile oil was collected, and the contents of monoterpene and atractylone in the components were determined by gas chromatography, and the results are shown in Table 2.

[0044] Table 2 Supercritical Extraction of Atr...

Embodiment 3

[0047] Example 3 The influence of extraction pressure on the extraction of Atractylodes macrocephala volatile oil

[0048] This example examines the effect of extraction pressure on the volatile oil of Atractylodes macrocephala. Put 200g of Atractylodes macrocephala medicinal material into the liner of the extractor, and seal it. By the method and parameter of embodiment 2, under the temperature of 308K, control supercritical CO 2 The pressure was 15-30MPa. After the volatile oil was extracted, the content of monoterpene and atractylone in the fraction was determined by gas chromatography. The results are shown in Table 3.

[0049] Table 3 Effect of extraction pressure on extraction of Atractylodes macrocephala volatile oil

[0050]

[0051] The results of this example show that under lower pressure, the extraction rate of volatile oil is lower, the main components are monoterpene components with lower molecular weight, and the content of atractylone is very low. As th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com