Copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and preparation method and application thereof

A copper-based catalyst, carbon dioxide technology, used in the preparation of metal/metal oxide/metal hydroxide catalysts, organic compounds, catalyst activation/preparation, etc., can solve problems such as poor methanol selectivity and achieve mutual synergy Strong, small particle size, high methanol selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

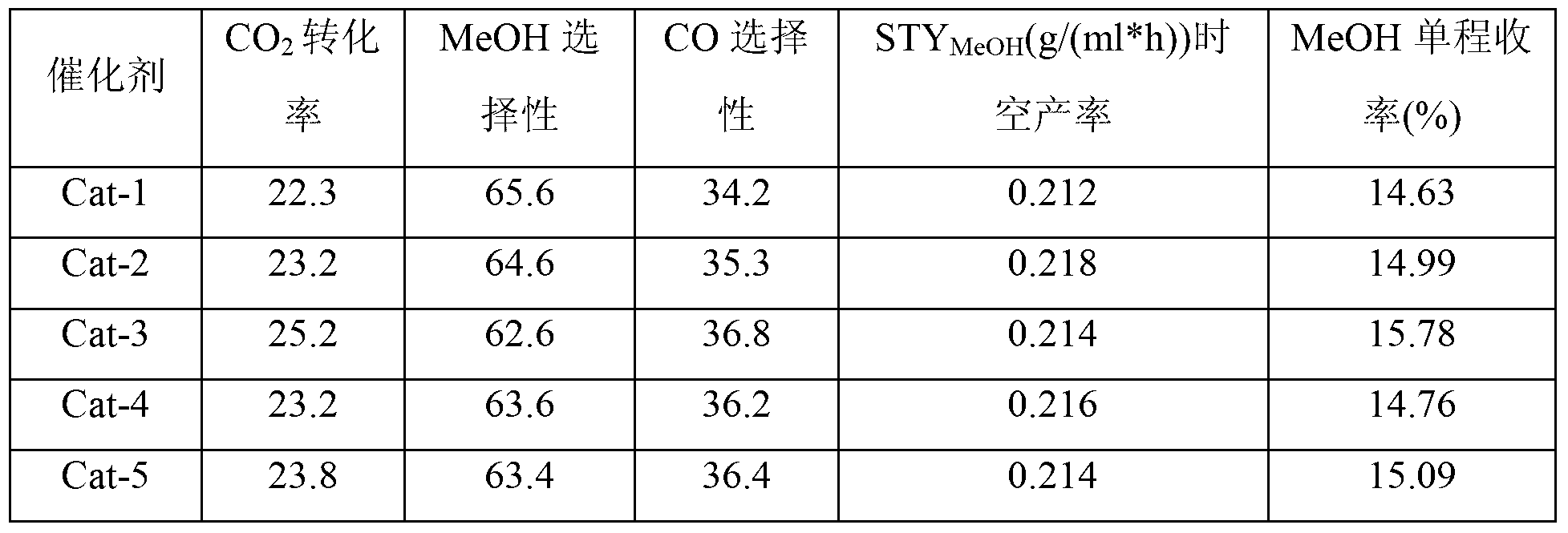

Examples

Embodiment 1

[0034] (1) Synthesize the copper-based catalyst according to the mole percentage of the following metal elements: Cu:Zn:Al:Zr=30:40:20:10. Weigh 72.48g of copper nitrate, 119g of zinc nitrate, 75.03g of aluminum nitrate and 23.12g of zirconyl nitrate according to the molar percentage of 30:40:20:10.

[0035] Firstly, zinc nitrate, aluminum nitrate and zirconyl nitrate were dissolved in 1L of deionized water successively to prepare mixed solution 1.

[0036] (2) Weigh 105.99g of sodium carbonate and 40g of sodium hydroxide at a molar ratio of 1:1, mix and dissolve them in deionized water, and prepare an alkaline precipitation solution 2 with a molar concentration of 1mol / L.

[0037] Under the conditions of a reaction temperature of 25°C and mechanical stirring, the co-precipitation method was used to co-precipitate the above 1L solution 1 and 1.8L solution 2, and control the pH of the precipitation to pH=8 to form a co-precipitation solution.

[0038] (3) Dissolve the copper n...

Embodiment 2

[0040] (1) Synthesize the copper-based catalyst according to the mole percentage of the following metal elements: Cu:Zn:Al:Zr=35:40:15:10. Weigh 62.17g of copper sulfate, 119g of zinc nitrate, 20g of aluminum chloride, 23.12g of zirconyl nitrate and 10g of polyvinylpyrrolidone according to the molar percentage of 35:40:15:10:1.

[0041] First, zinc nitrate, aluminum chloride, zirconyl nitrate and polyvinylpyrrolidone were dissolved in 1L of deionized water in sequence to prepare mixed solution 1.

[0042](2) Weigh 138.21g of potassium carbonate and 40g of sodium hydroxide at a molar ratio of 1:1, dissolve them in deionized water, and prepare an alkaline precipitation solution 2 with a molar concentration of 1mol / L.

[0043] Under the conditions of a reaction temperature of 25°C and mechanical stirring, the co-precipitation method was used to co-precipitate the above 1L solution 1 and 1.7L solution 2, and control the pH of the precipitate to pH=9 to form a co-precipitation solu...

Embodiment 3

[0046] (1) Synthesize the copper-based catalyst according to the mole percentage of the following metal elements: Cu:Zn:Al:Zr=40:40:10:10. First weigh 96.64g of copper nitrate, 54.52g of zinc chloride, 37.51g of aluminum nitrate, 32.23g of zirconium oxychloride and 20g of polyvinylpyrrolidone according to the molar percentage of 40:40:10:10:2.

[0047] First, zinc chloride, aluminum nitrate, zirconium oxychloride and polyvinylpyrrolidone were dissolved in 1L of deionized water in sequence to prepare mixed solution 1.

[0048] (2) Weigh 121.89g of sodium carbonate and 64.53g of potassium hydroxide at a molar ratio of 1:1, dissolve them in deionized water, and prepare an alkaline precipitation solution 2 with a molar concentration of 1mol / L.

[0049] Under the conditions of a reaction temperature of 25°C and mechanical stirring, the co-precipitation method was used to co-precipitate the above 1L solution 1 and 1.65L solution 2, and control the pH of the precipitate to pH=10 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com