Carbon fiber compound nano copper cobalt alloy catalyst for low-carbon alcohol synthesis and preparation method of catalyst

A carbon fiber and catalyst technology, applied in the field of metal catalysts, can solve problems such as inability to achieve breakthroughs in nano-cobalt-copper alloy catalysts, and achieve the effects of not easy to sinter and grow, high low temperature activity, and high activity specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

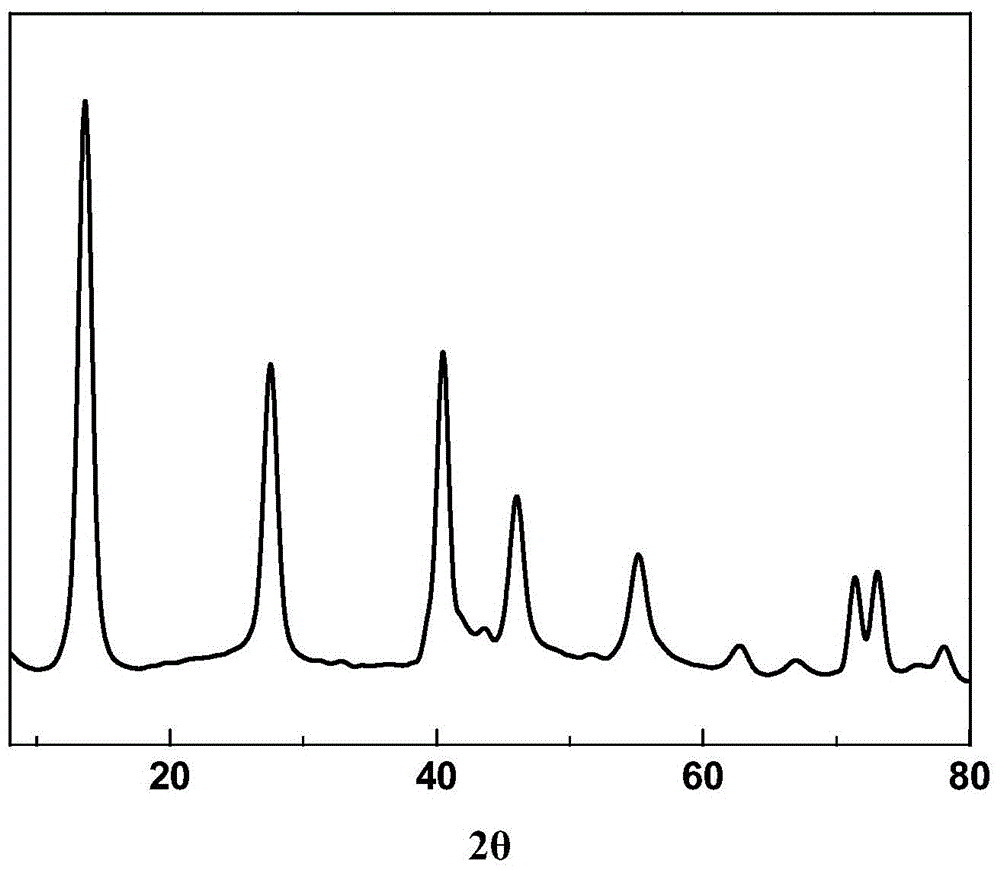

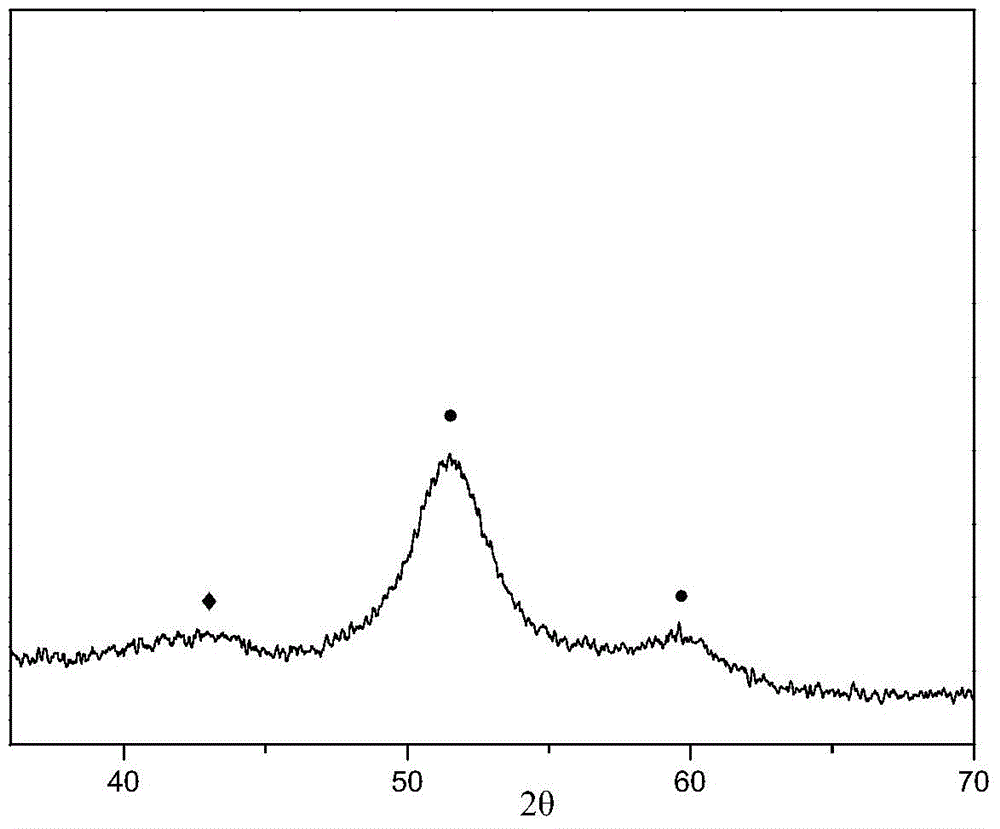

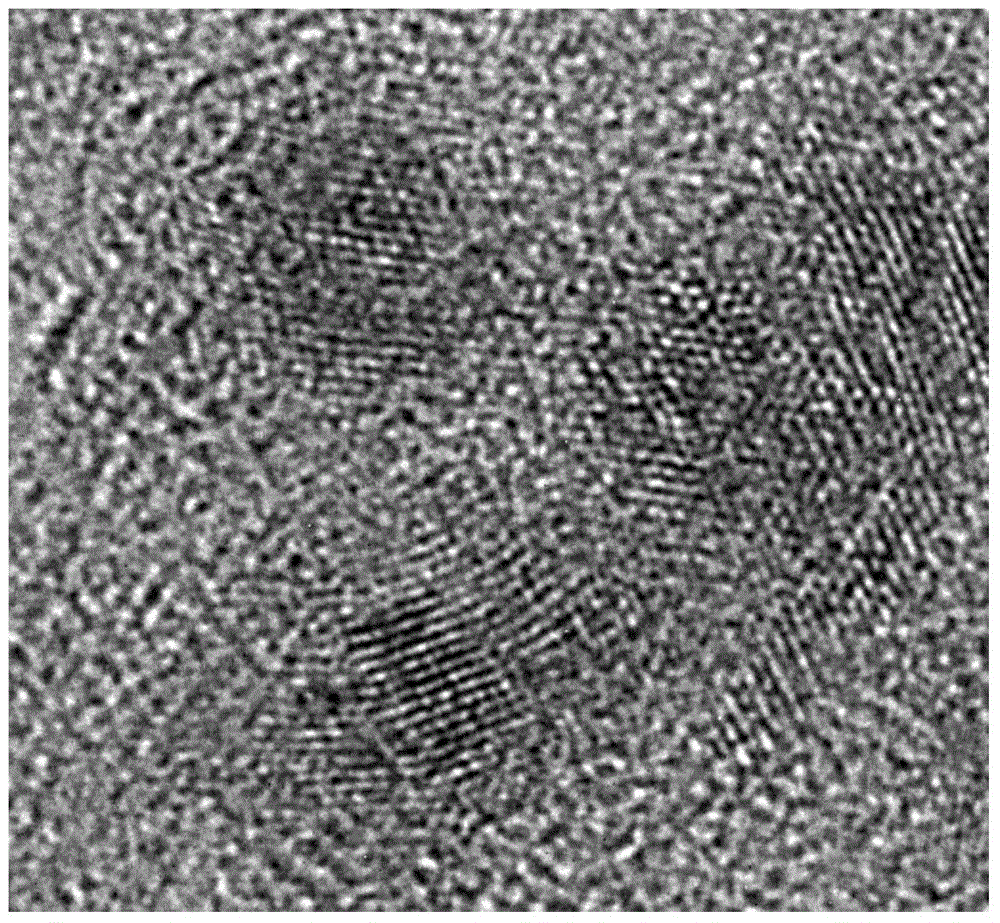

[0044] Above-mentioned a kind of preparation method that is used for syngas to prepare the catalyst of low carbon alcohol, comprises the following steps:

[0045] 1) Add carbon fiber, 98% (w / w) sulfuric acid, 65% (w / w) nitric acid to a dry container, after ultrasonication for 2-5 hours, reflux at 100°C for 2-6 hours, suction filter and wash, at 60-100 Dry at ℃ for 12-48h to obtain acidified carbon fiber, the carbon fiber, 98% (w / w) sulfuric acid, 65% (w / w) nitric acid mass ratio is 1: (30-45): (10-15 ).

[0046] 2) according to the mol ratio of the nitrate of copper nitrate, cobalt nitrate, aluminum nitrate and additive M ion is 1: (0.4-3): (1.5-10): (0-14), the nitric acid of copper, cobalt and aluminum One or more of salt and additives such as zinc, manganese, magnesium, calcium, nickel, iron and chromium nitrates are added to deionized water to make a mixed solution with a total ion concentration of 0.01-2mol / L, which is recorded as solution A ; by NaOH and Na 2 CO 3 Th...

Embodiment 1

[0051] Add carbon fiber, 98% (w / w) sulfuric acid, 65% (w / w) nitric acid to a dry container, ultrasonicate for 2 hours, reflux at 100°C for 2 hours, filter and wash with suction, dry at 60°C for 12 hours to obtain acidification treatment The mass ratio of the above-mentioned carbon fiber, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid is 1:30:10. Weigh 25g of carbon fiber and disperse it in 15L of deionized water to obtain a carbon fiber dispersion;

[0052] The molar ratio of copper nitrate, cobalt nitrate and aluminum nitrate is 1:2:1.5 to prepare a mixed salt solution with a total metal concentration of 2mol / L, which is recorded as solution A; 2 CO 3 )=1.33mol / L and c(NaOH)=2mol / L are made into mixed alkali solution and denoted as B. Add solution A and solution B into the reactor containing the above-mentioned carbon fiber dispersion in parallel, and control the pH value to 7. After the solution A is added dropwise, let it stand for 12 hours at a temperature of 80°C. A...

Embodiment 2

[0059] Add carbon fiber, 98% (w / w) sulfuric acid, 65% (w / w) nitric acid to a dry container, ultrasonicate for 3 hours, reflux at 100°C for 3 hours, filter and wash with suction, dry at 70°C for 20 hours to obtain acidification treatment The mass ratio of the above-mentioned carbon fiber, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid is 1:35:10. Weigh 2g of carbon fiber and disperse it in 15L deionized water to obtain a carbon fiber dispersion;

[0060] The molar ratio of copper nitrate, cobalt nitrate, aluminum nitrate and zinc nitrate is 1:2:1.5:1.5 to make a mixed salt solution with a total metal concentration of 1.5mol / L, which is recorded as solution A; 2 CO 3)=2.25mol / L and c(NaOH)=3mol / L are made into mixed alkaline solution and denoted as B. Add solution A and solution B into a 1.5L reactor with a concentration of 2.7g / L carbon fiber dispersion in parallel, and control the pH value to 8. After the solution A is added dropwise, let it stand for 12 hours at a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com