Catalyst for low-carbon mixed alcohol synthesis from syngas, and preparation method and application thereof

A low-carbon mixed alcohol and synthesis gas technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of active component agglomeration, achieve high selectivity, high total alcohol selectivity, Good running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, and the present invention includes but not limited to the following examples.

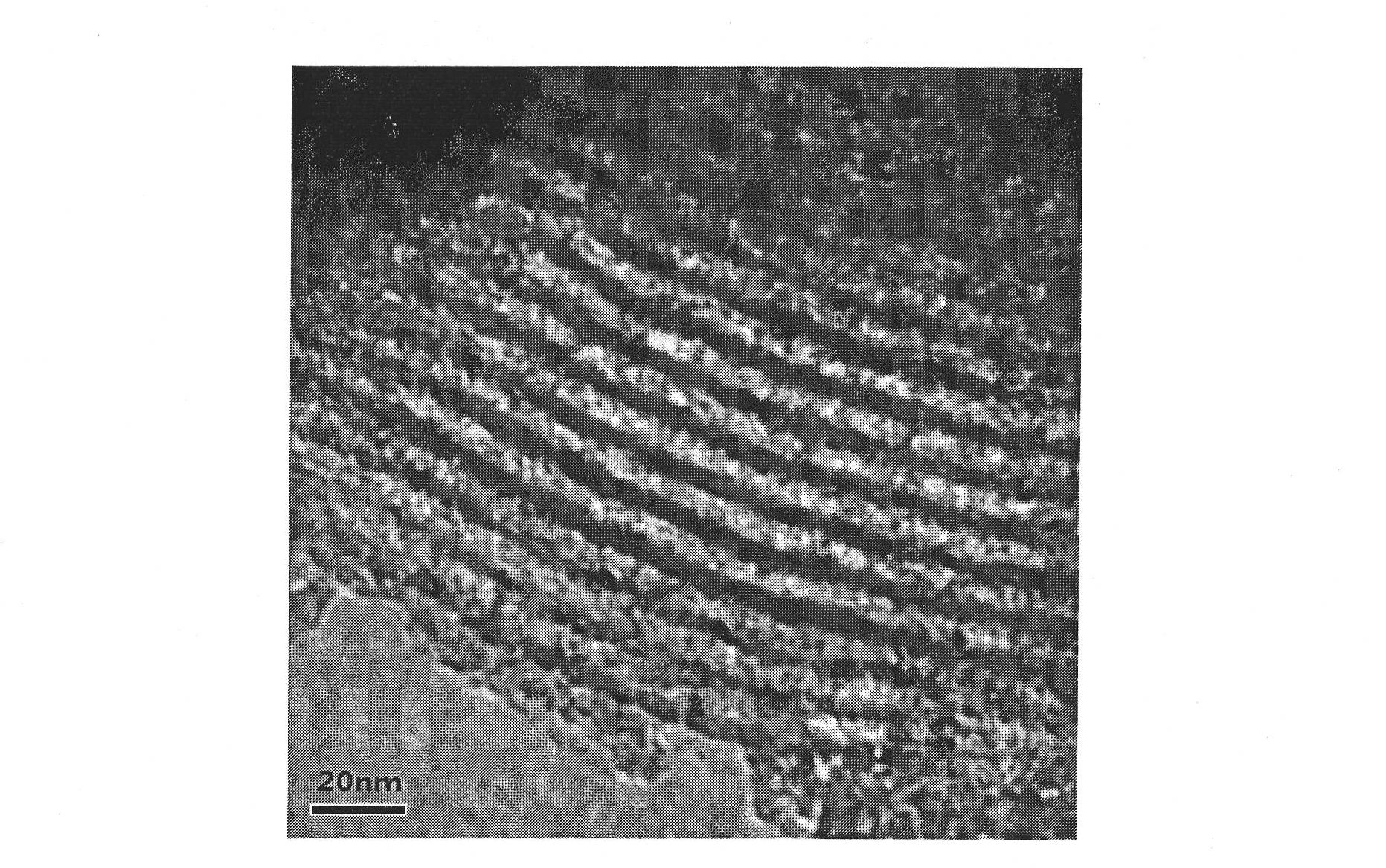

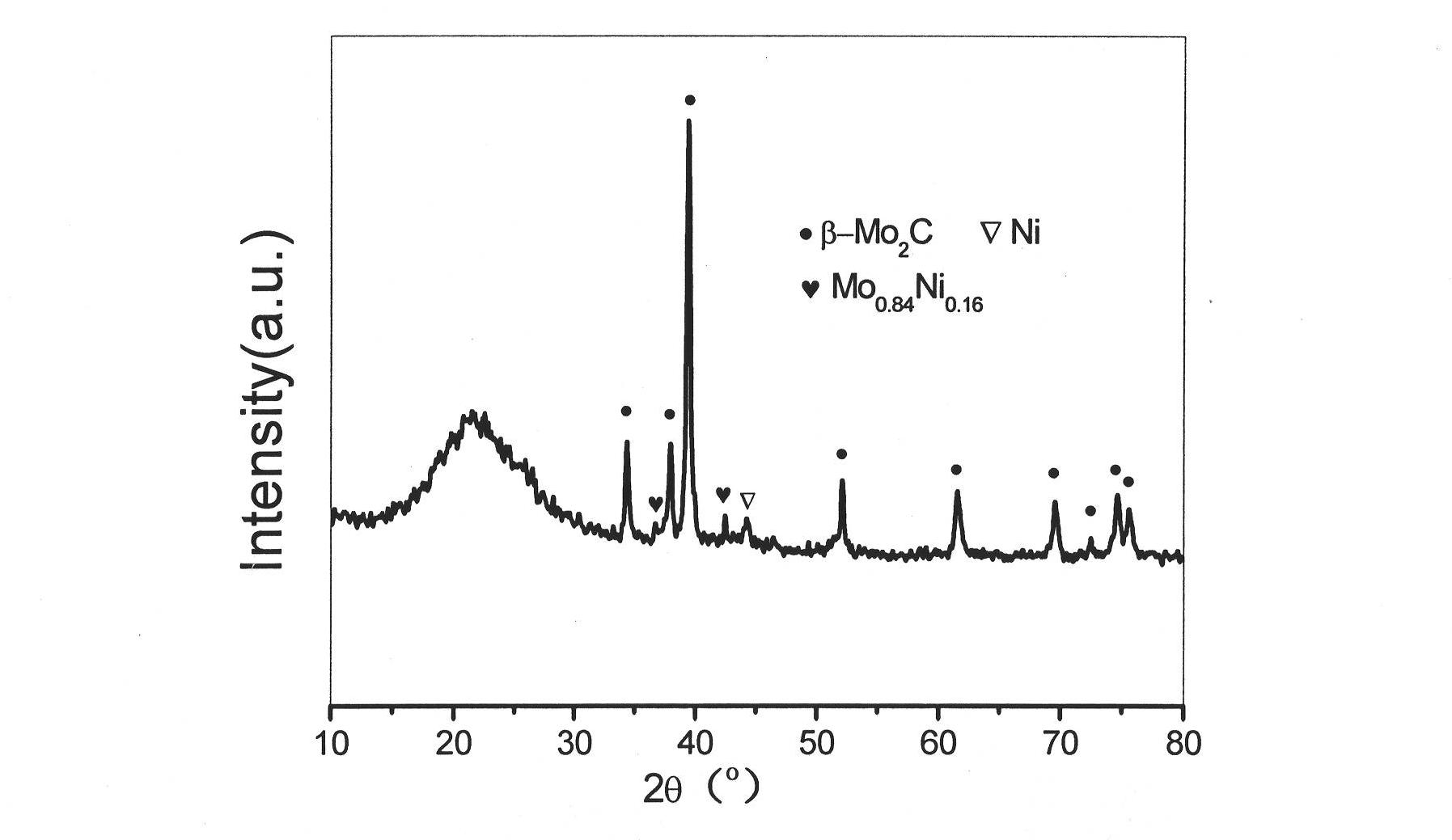

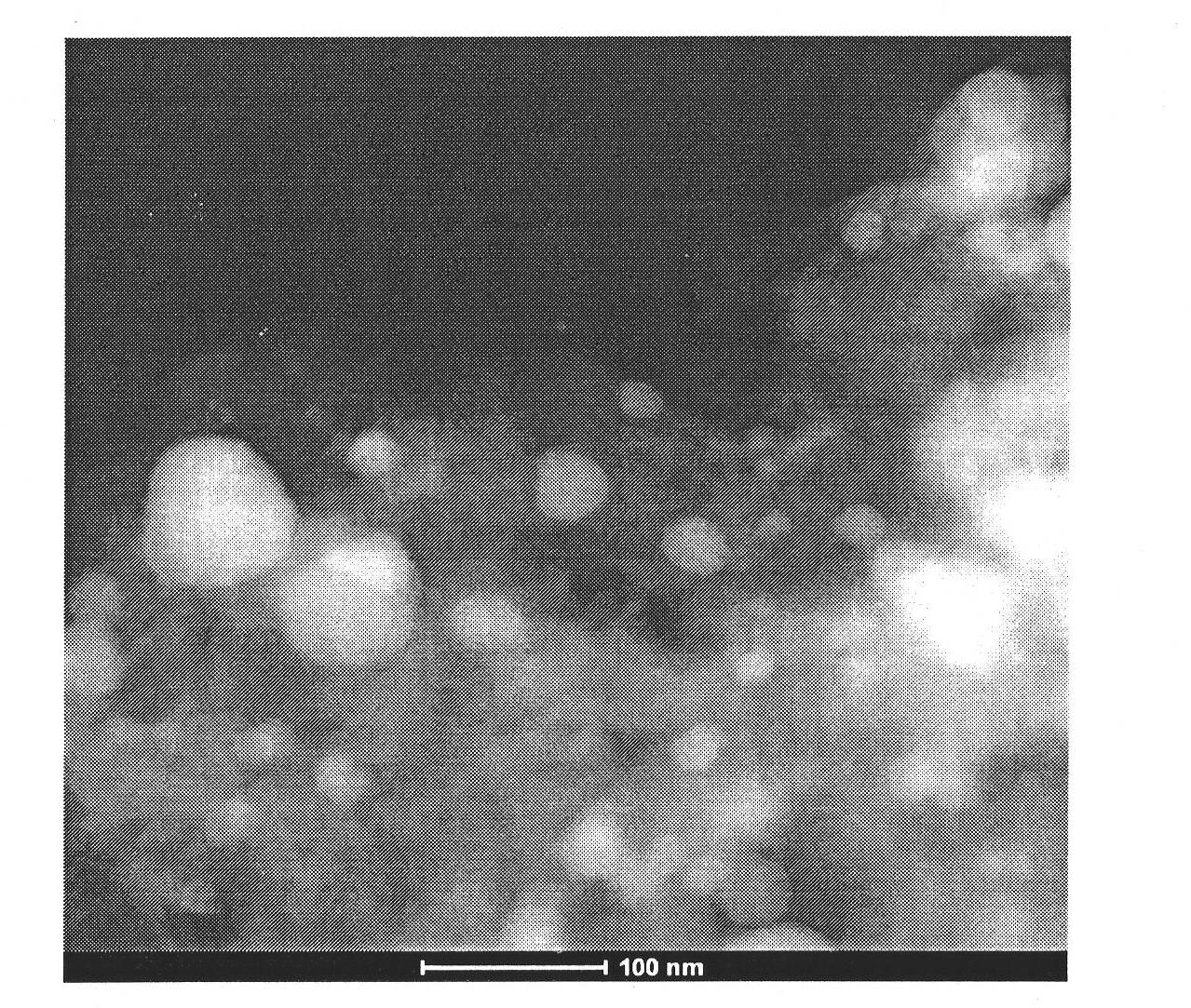

[0023] Weigh 4.0g of P123 into a 250mL beaker, add 90mL of deionized water and stir, pour it into a 500mL three-necked flask after it is completely dissolved, transfer 60g of hydrochloric acid (4M), and continue stirring in a 40°C constant temperature water bath for 0.50h . Weigh 8.50g of TEOS, and slowly add TEOS dropwise into the three-necked flask with a constant pressure funnel, and the dropwise addition time is 1h; after the dropwise addition, continue to stir for 23h. The solution in the three-neck flask was transferred into a stainless steel reaction kettle (Teflon bottle) with a polytetrafluoroethylene substrate, and was placed in a constant temperature drying oven at 100° C. for 24 hours for crystallization. Take out the Teflon bottle, cool to room temperature naturally, filter the solution in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com