System and process for preparing methyl alcohol through coke-oven gas-assisted coal gasification

A technology for coal gasification and coke oven gas, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, and the petroleum industry. Flexibility, reduced equipment investment, and low system flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific implementation of the coke oven gas assisted coal gasification methanol production system in this embodiment is as follows:

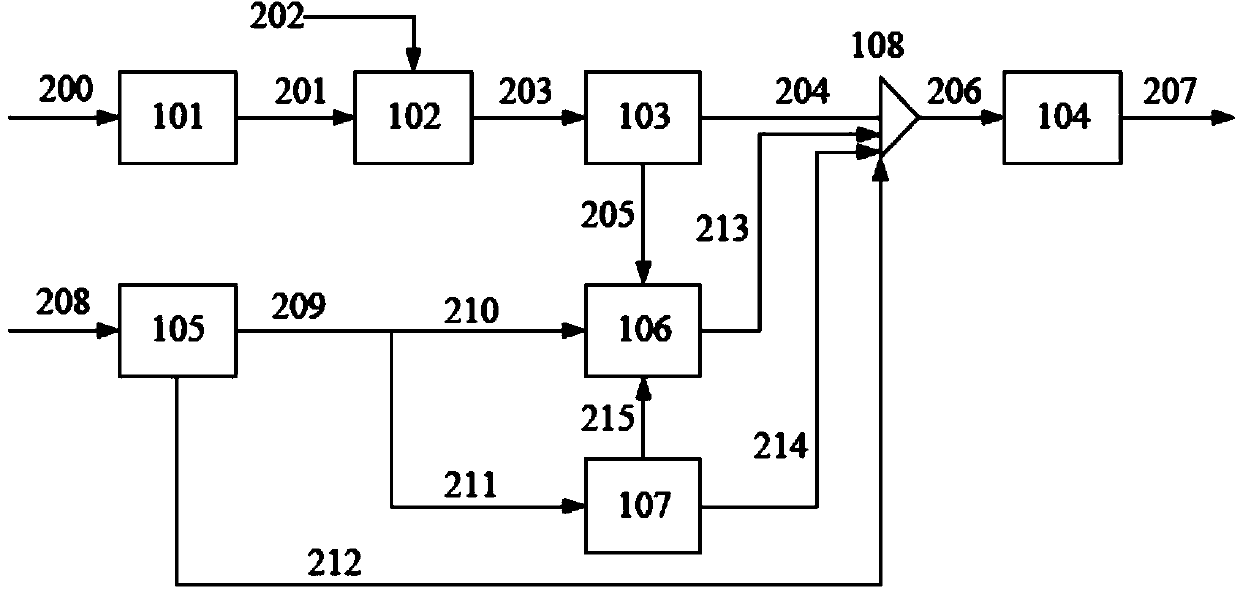

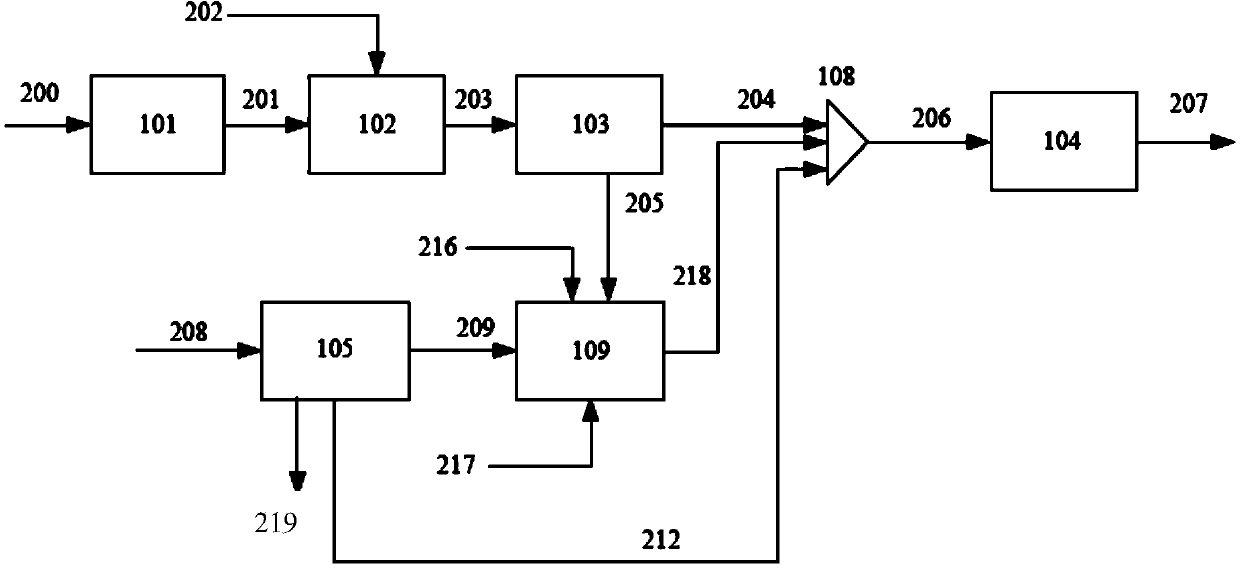

[0038] The raw coal flow rate entering the process of the present invention is 250t / h. The raw material coke oven gas flow rate is 350t / h. The composition of coke oven gas is shown in Table 1. Coke oven gas-assisted coal-to-methanol process flow diagram see figure 2 :

[0039] Raw coal 200 is made into coal-water slurry 201 by the coal-water slurry preparation unit, and then enters the coal gasification unit 101 for coal gasification reaction together with oxygen 202 to produce coal gasification crude synthesis gas 203; the coal gasification crude synthesis gas 203 enters the synthesis gas purification Unit 103 removes sulfide and carbon dioxide to obtain purified coal gasification synthesis gas 204 and carbon dioxide 205;

[0040] Raw material crude coke oven gas 208 enters coke oven gas purification and separation unit 105, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com