Preparation method and application of catalyst for treating acrylonitrile contained waste gas

A technology for waste gas treatment and acrylonitrile, applied in physical/chemical process catalysts, chemical instruments and methods, combustion methods, etc., can solve problems such as waste gas pollution containing acrylonitrile, achieve high selectivity, low energy consumption, and light-off temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

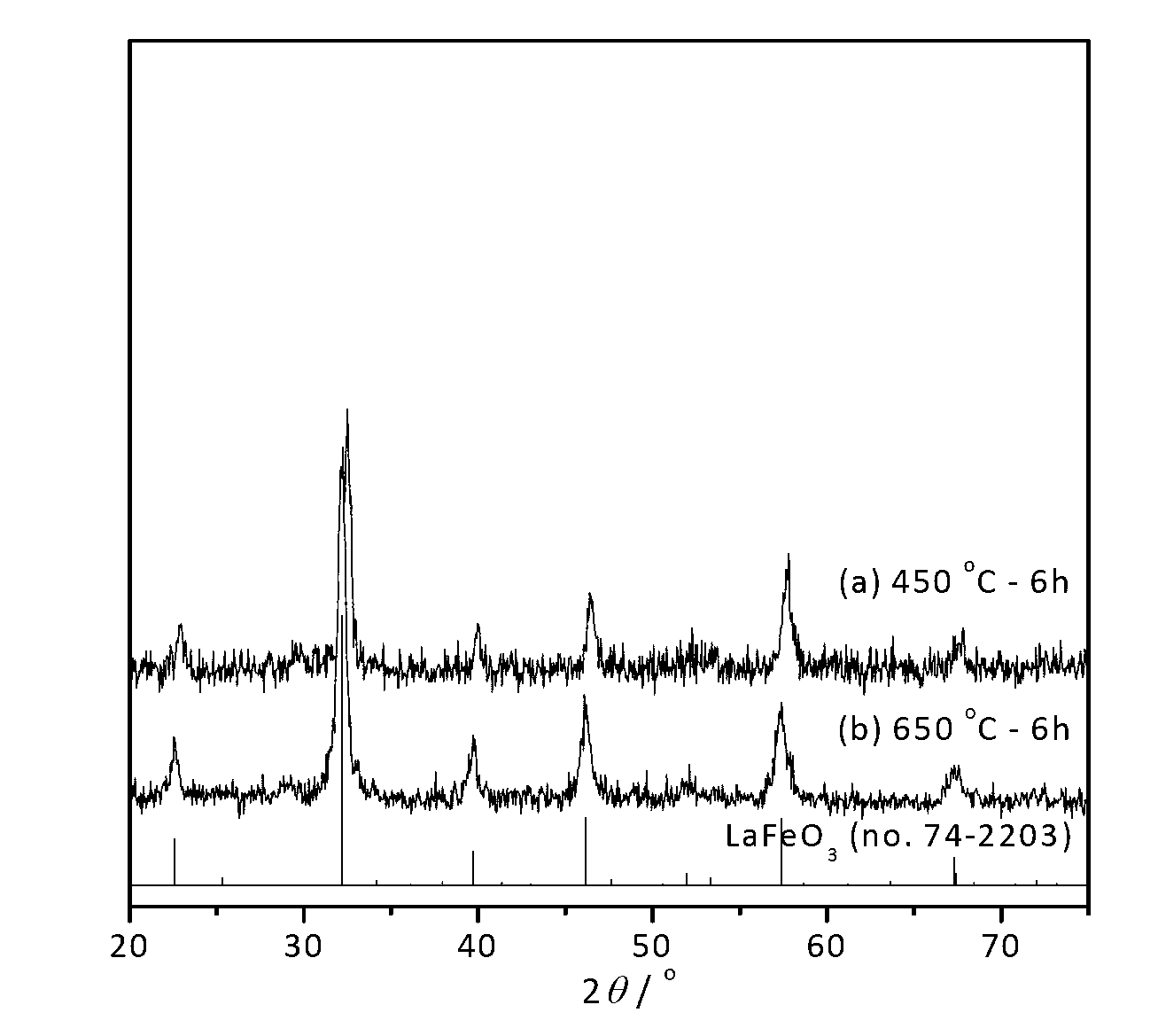

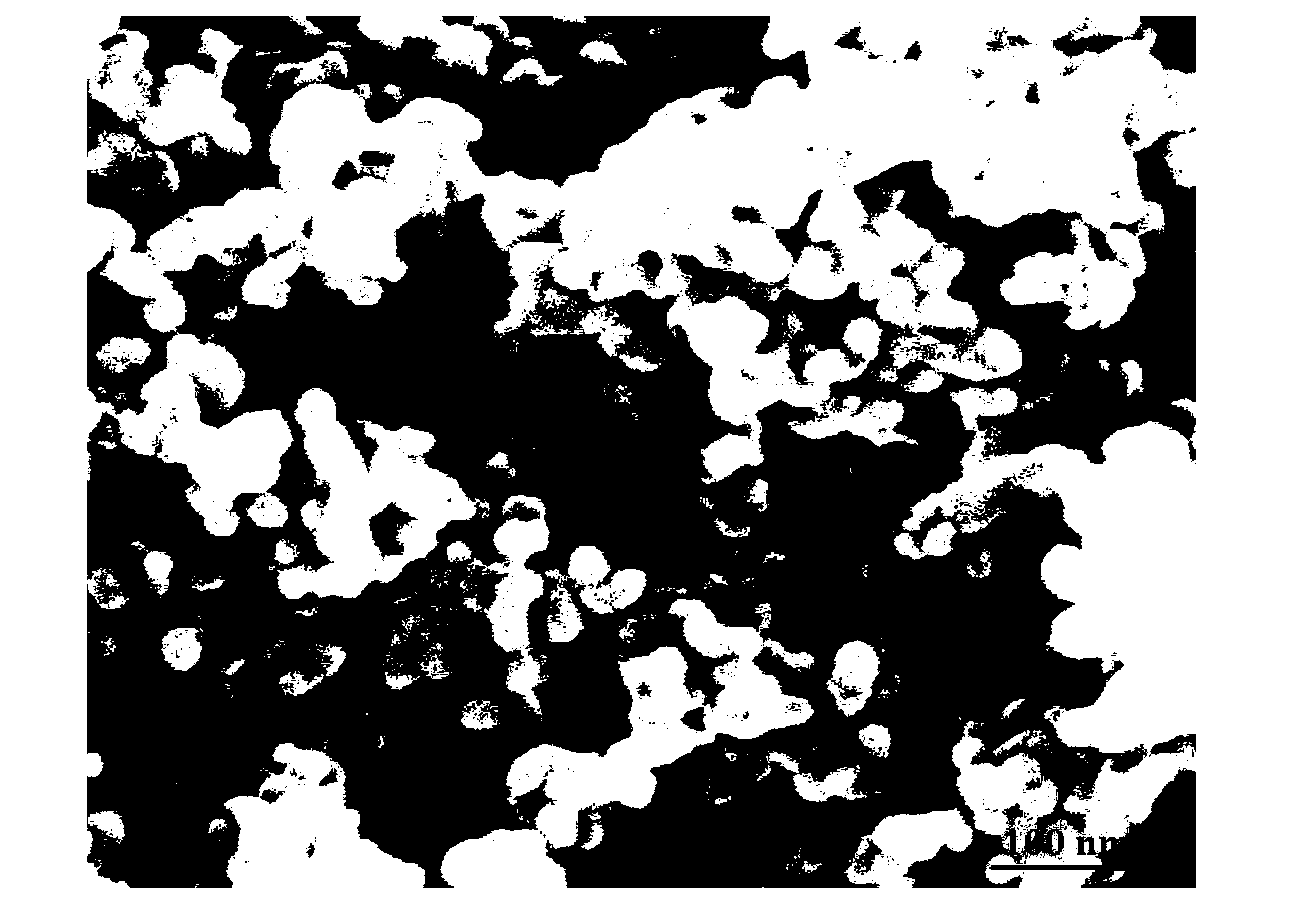

Embodiment 1

[0022] Embodiment 1: Measure 60ml of benzyl alcohol and pour it into a 100ml small beaker, add a magnetic stirring bar and stir and heat in a constant temperature magnetic stirrer, and set the temperature to 80°C. Weigh 2.209 grams of lanthanum nitrate and pour it into a small beaker. After it is completely dissolved, add 1.802 grams of iron acetylacetonate. After 20 minutes, the mixed solution is transferred to a high-pressure static reactor. Reactor is put into the oven that temperature is 200 ℃, maintains 24 hours, takes out afterwards. Centrifuge with a centrifuge (8000 rpm, 10 minutes), pour off the upper layer solution, wash with absolute ethanol, and centrifuge twice. The resulting precipitate was mixed with absolute ethanol, transferred to a drying dish, and dried in an oven. Grind the loose powder to make the particles fine enough. Put it into a muffle furnace and bake at 450°C for 6 hours. Finally, the metal oxide LaFeO with perovskite crystal form was obtained 3...

Embodiment 2

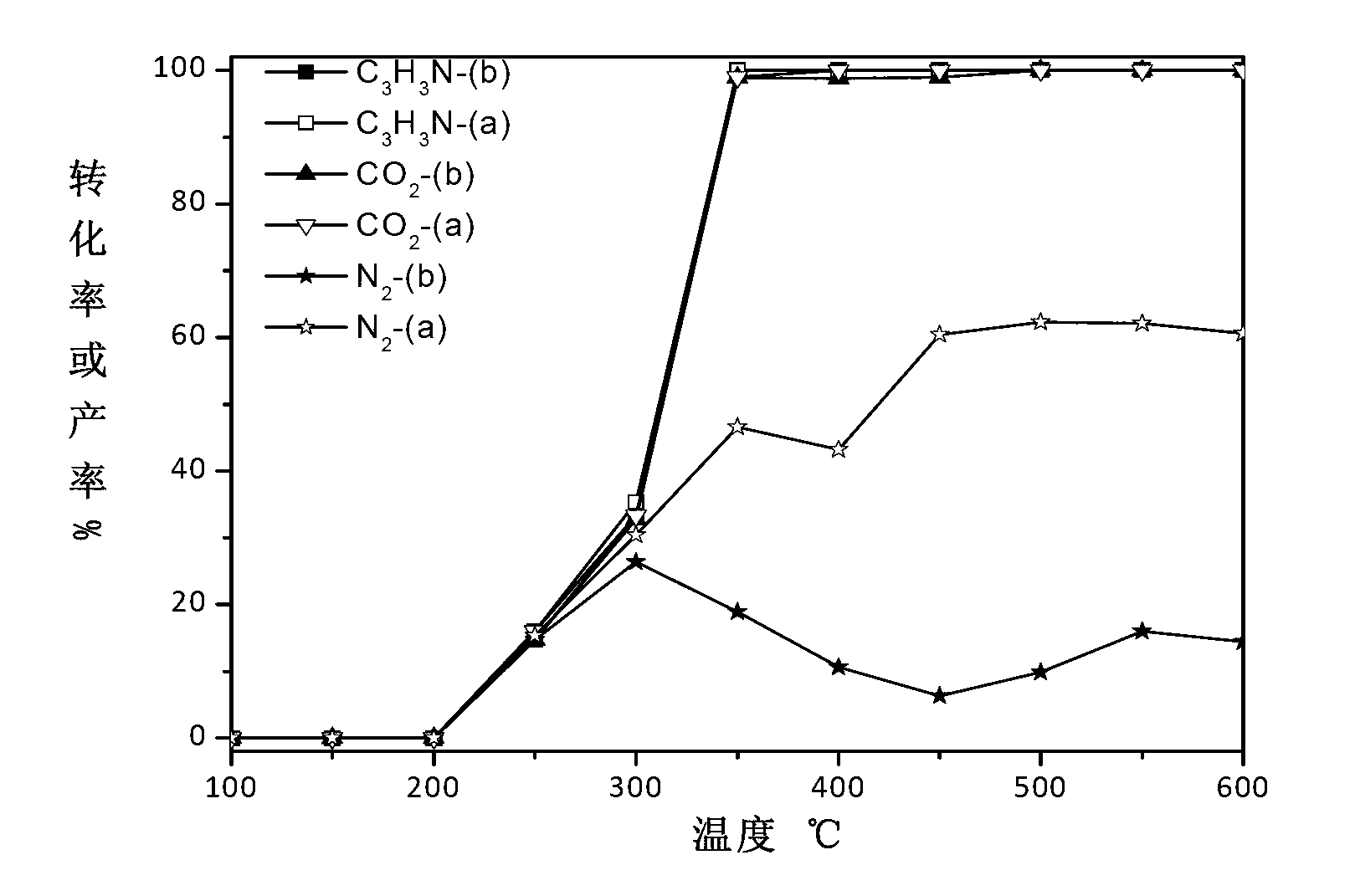

[0024] Embodiment 2: LaFeO obtained by the preparation method of catalyst in embodiment 1 3 , under the condition that the volume ratio of acrylonitrile and oxygen is 0.3:1.0, the activity evaluation is carried out, and other conditions are all the same as in Example 1, and the obtained experimental results are shown in Figure 4 .

Embodiment 3

[0025] Embodiment 3: LaFeO obtained by the preparation method of catalyst in embodiment 1 3 , under the condition that acrylonitrile and oxygen volume ratio are 0.3:8.0, carry out activity evaluation, other conditions are all the same as embodiment 1, gained experimental result sees Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com