Method for producing methyl alcohol and derivatives of methyl alcohol by coal underground gasification product gases

A technology for underground gasification and product gas, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problem of not considering optimal utilization in detail, and achieve the effect of increasing production and sales revenue and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

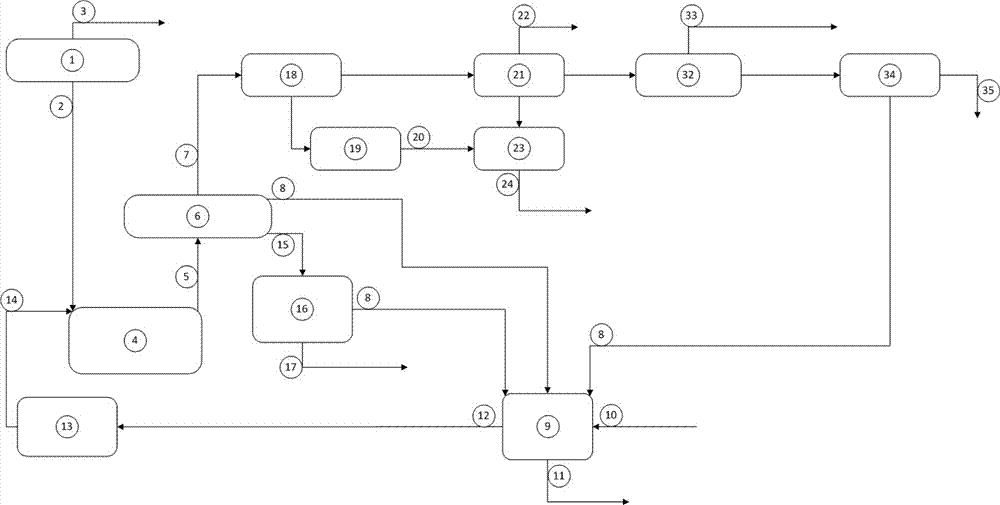

[0049] In one embodiment, methanol is produced from underground coal gasification product gas ( figure 1 ), the air separation unit (ASU) 1 is used to produce liquid oxygen (LOX) with a concentration higher than 90mole%, and 2 is used for the pure oxygen gasification of underground coal gasification. At the same time, the air separation unit (ASU) 1 also produces nitrogen 3, which can be used as utilities for the entire process, such as ISC underground gasifier 4 purge, pipeline and equipment purge, project start-up and shutdown purge, etc. When higher pressure nitrogen is required, a booster compressor is used to provide the required supply pressure. High-concentration liquid oxygen (LOX)2 also passes through the booster pump, increasing the oxygen supply pressure. Gaseous oxygen (GOX) 2 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com