Carbon nano tube composite nanometer cobalt-copper alloy catalyst for low-carbon alcohol synthesis and preparation method of carbon nano tube composite nanometer cobalt-copper alloy catalyst

A carbon nanotube composite and carbon nanotube technology, which is applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of inability to achieve nano-cobalt-copper alloy catalyst breakthroughs, etc. problems, to achieve the effects of not easy sintering growth, high selectivity of low-carbon alcohols, and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

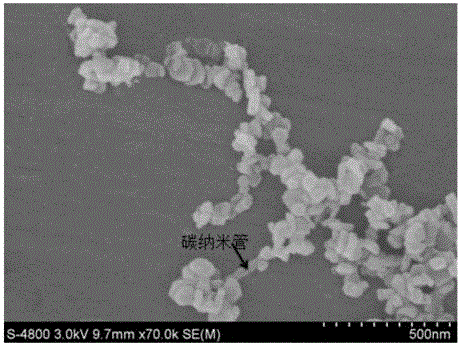

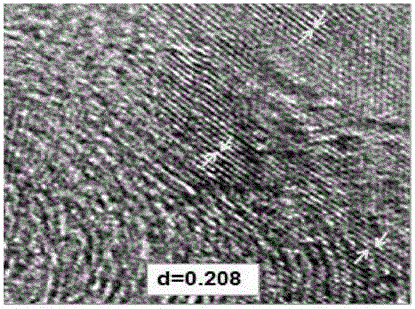

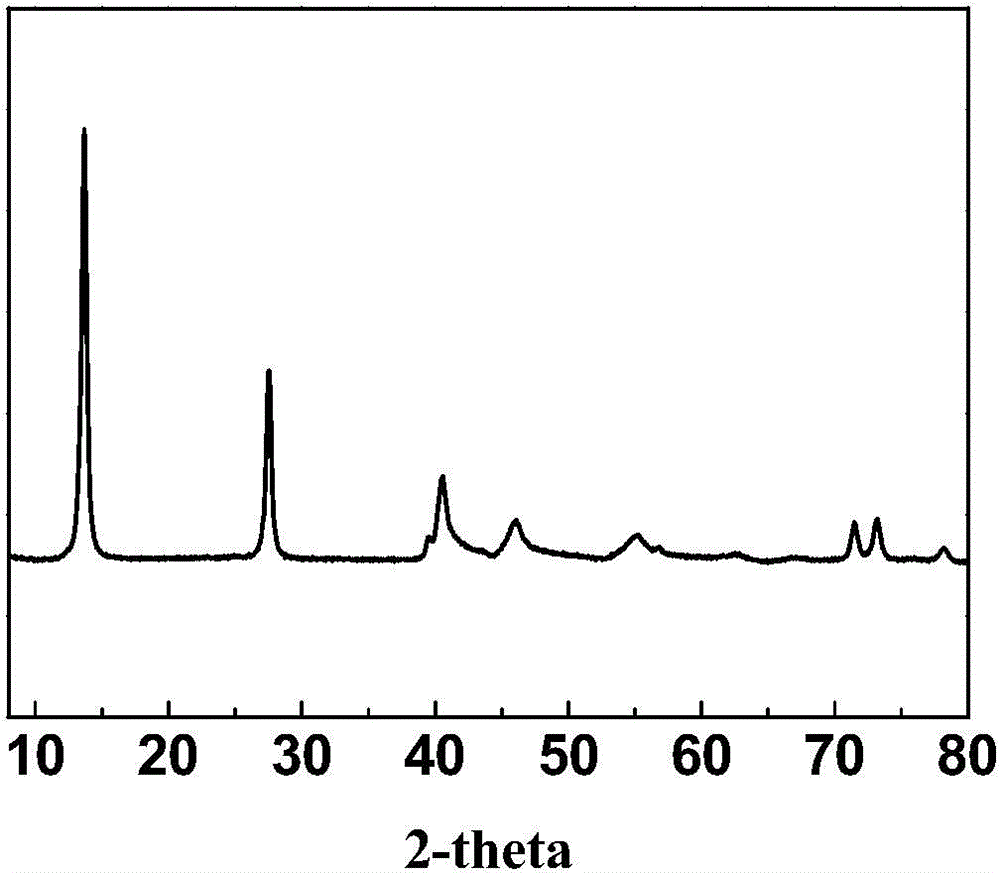

[0035] Add carbon nanotubes, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid to a dry container, after ultrasonication for 2 hours, reflux at 100°C for 2h, filter and wash, and dry at 60°C for 12h to obtain For the acidified carbon nanotubes, the carbon nanotubes, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid have a mass ratio of 1:30:10. Weigh 25g of carbon nanotubes and disperse them in 15L of deionized water to obtain a carbon nanotube dispersion;

[0036] The molar ratio of copper nitrate, cobalt nitrate and aluminum nitrate is 1:2:1.5 to prepare a mixed salt solution with a total metal concentration of 1mol / L, which is recorded as solution A; 2 CO 3 )=0.66mol / L and c(NaOH)=4.1mol / L are made into mixed alkaline solution and denoted as B. Add solution A and solution B into the reactor containing the above-mentioned carbon nanotube dispersion in parallel, and control the pH value to 9.5. After the solution A is added dropwise, age for 12 hours at a temperature of 8...

Embodiment 2

[0042] Add carbon nanotubes, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid into a dry container, ultrasonicate for 3 hours, reflux at 100°C for 3h, wash with suction, and dry at 70°C for 20h to obtain For the acidified carbon nanotubes, the carbon nanotubes, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid have a mass ratio of 1:35:10. Weigh 2g of carbon nanotubes and disperse them in 15L of deionized water to obtain a carbon nanotube dispersion;

[0043] The molar ratio of copper nitrate, cobalt nitrate, aluminum nitrate and zinc nitrate is 1:2:1.5:2 to make a mixed salt solution with a total metal concentration of 1mol / L, which is recorded as solution A; 2 CO 3 )=0.58mol / L and c(NaOH)=1.0mol / L are made into mixed alkaline solution and denoted as B. Add solution A and solution B into a 1.5L reactor with a concentration of 2.7g / L carbon nanotube dispersion in parallel, and control the pH value to 9.7. After the solution A is added dropwise, age at a temperature of 70°...

Embodiment 3

[0046] Add carbon nanotubes, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid to a dry container, and after ultrasonication for 4 hours, reflux at 100°C for 4h, filter and wash, and dry at 80°C for 24h to obtain For the acidified carbon nanotubes, the carbon nanotubes, 98% (w / w) sulfuric acid, and 65% (w / w) nitric acid have a mass ratio of 1:40:10. Weigh 15g of carbon nanotubes and disperse them in 15L of deionized water to obtain a carbon nanotube dispersion;

[0047]The molar ratio of copper nitrate, cobalt nitrate, aluminum nitrate and magnesium nitrate is 1:2:6:2 to make a mixed salt solution with a total metal concentration of 0.5mol / L, which is recorded as solution A; according to c(Na2CO3)=1.35 mol / L and c(NaOH)=2.5mol / L to form a mixed alkali solution. Add solution A and solution B concurrently into a 1.0L reactor with a concentration of 3.0g / L carbon nanotube dispersion, and control the pH value to 10.5. After the solution A is added dropwise, age for 24 hours at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com