High-CO equal-temperature transformation process for matched methyl alcohol synthesis

A technology of isothermal transformation and methanol synthesis, which is applied in the field of temperature transformation technology, to achieve the effects of avoiding overheating, long service life and increasing control means

Active Publication Date: 2018-12-25

SINOPEC NINGBO ENG +2

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The technical problem to be solved by the present invention is to provide a crude gas shift process for high CO concentration in view of the current state of the art, which can effectively solve the problem of overheating of the traditional adiab

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

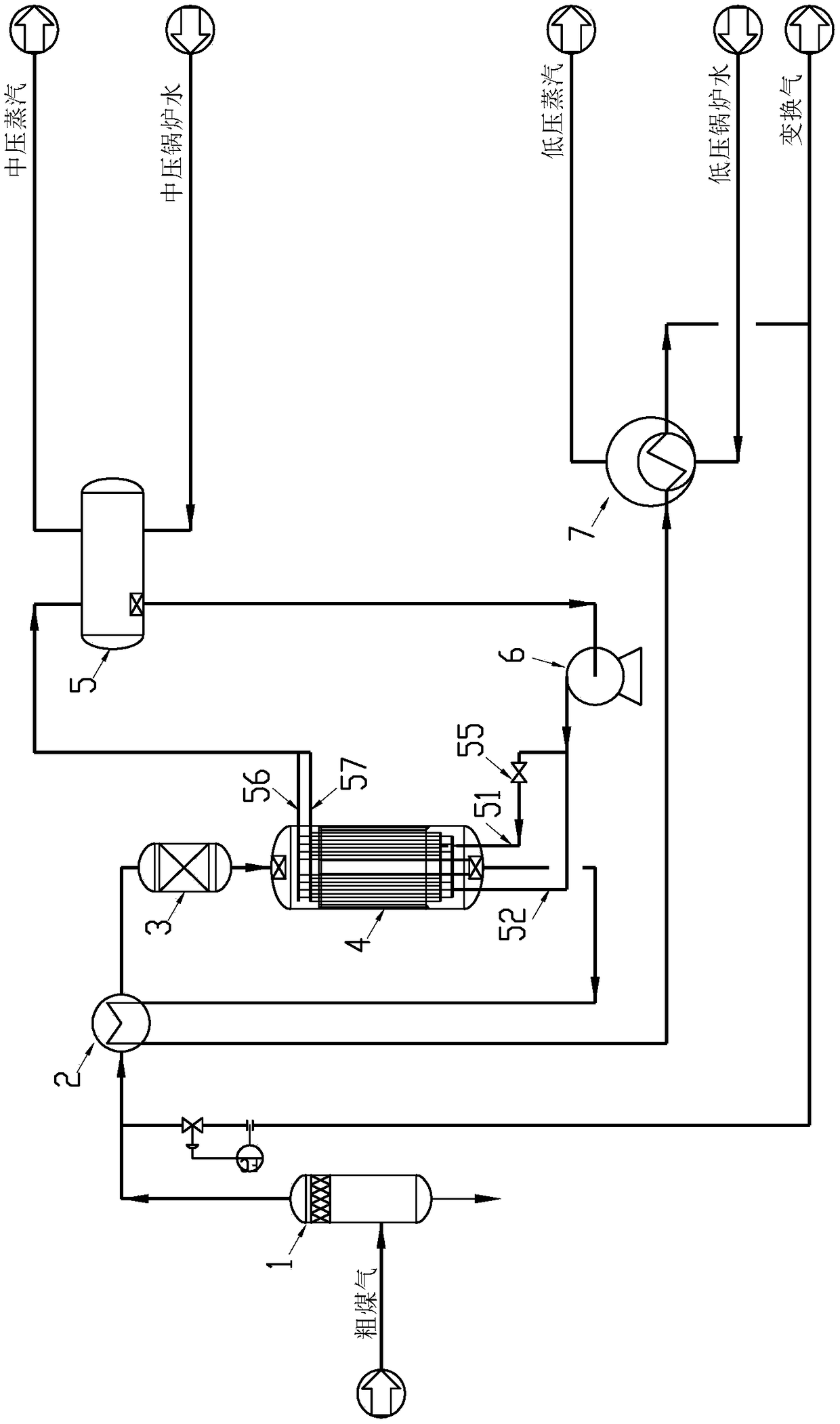

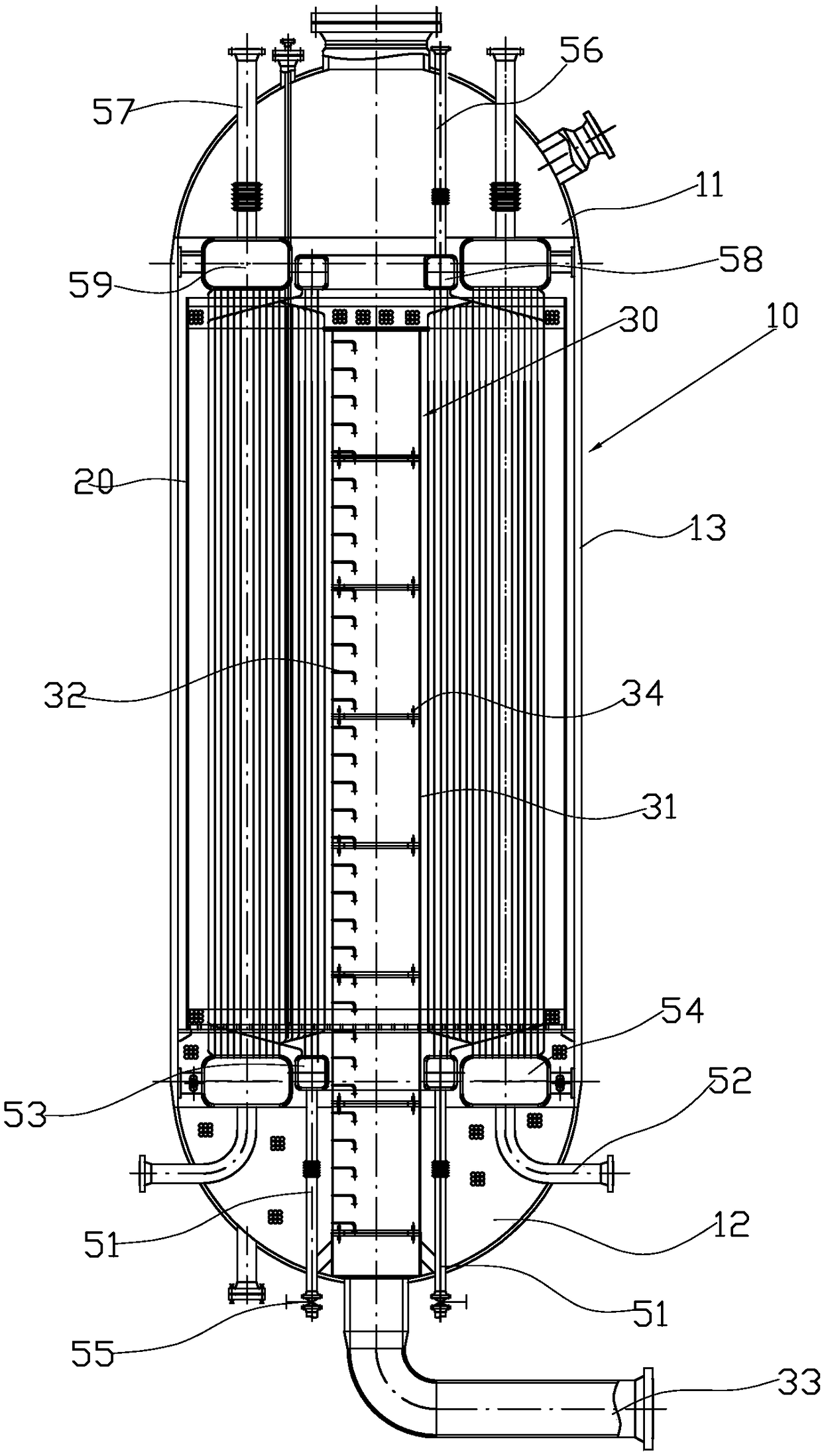

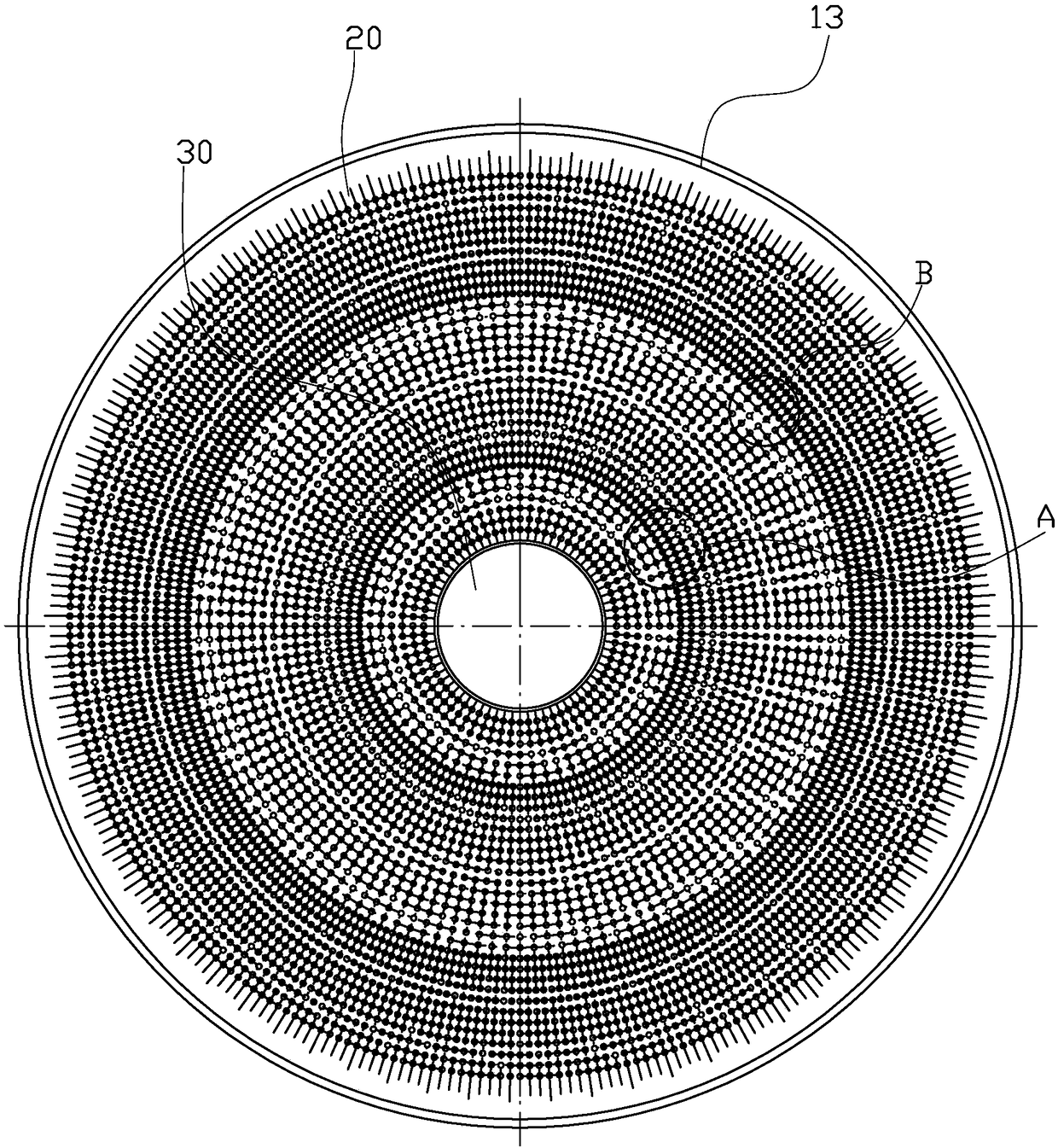

The invention relates to a high-CO equal-temperature transformation process for matched methyl alcohol synthesis. The process adopts an equal-temperature transformation furnace, two groups of heat exchange tubes are arranged in the equal-temperature transformation furnace, raw gas from a gas chemical engineering section is divided into two strands, the first strand serves as non-transformation gas, and the second strand serves as a transformation gas furnace. At the early running stage of the furnace, the second strand of raw gas exchanges heat to reach the temperature of 250-265 DEG C and then enters the equal-temperature transformation furnace, the two groups of heat exchange tubes simultaneously work, and the temperature of exit transformation gas of the equal-temperature transformationfurnace is 280-295 DEG C. At the later running stage of the furnace, the second strand of raw gas exchanges heat to reach the temperature of 265-280 DEG C and then enters the equal-temperature transformation furnace, and the temperature of the exit transformation gas of the equal-temperature transformation furnace is 295-310 DEG C. The heat of the transformation gas is recycled, and the transformation gas and the first strand of raw gas are combined and then conveyed into a methyl alcohol synthesis device. According to the process, the heat-exchange area is changed at the later stage, so thatactivation temperature requirements of a declined catalyst are met, the problem of high device investment caused by pressure fluctuation of a steam pipe network is avoided, and constancy of transformation rate is maintained.

Description

technical field [0001] The invention relates to the technical field of carbon monoxide conversion, and specifically refers to a high-CO isothermal conversion process supporting methanol synthesis. Background technique [0002] Since the beginning of the 21st century, my country's chemical industry using coal as raw material has developed rapidly. Starting from the shell pulverized coal gasification process introduced in the Netherlands, a variety of independent coal gasification processes have been developed. CO in the raw gas produced by such processes The dry basis content is generally high, reaching more than 60%. For the production equipment that adopts the gasification process to produce syngas and downstream C1 chemical products, it is generally necessary to remove CO in the raw material gas through a shift reaction, which consumes water vapor to produce H2, while changing CO into CO2 which is easy to remove. Downstream products include hydrogen production, synthetic am...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B32/40C07C29/151C07C31/04

CPCC01B32/40C07C29/1518C07C31/04Y02P20/50

Inventor 涂林许仁春施程亮张志国魏彤李怀双郭航

Owner SINOPEC NINGBO ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com