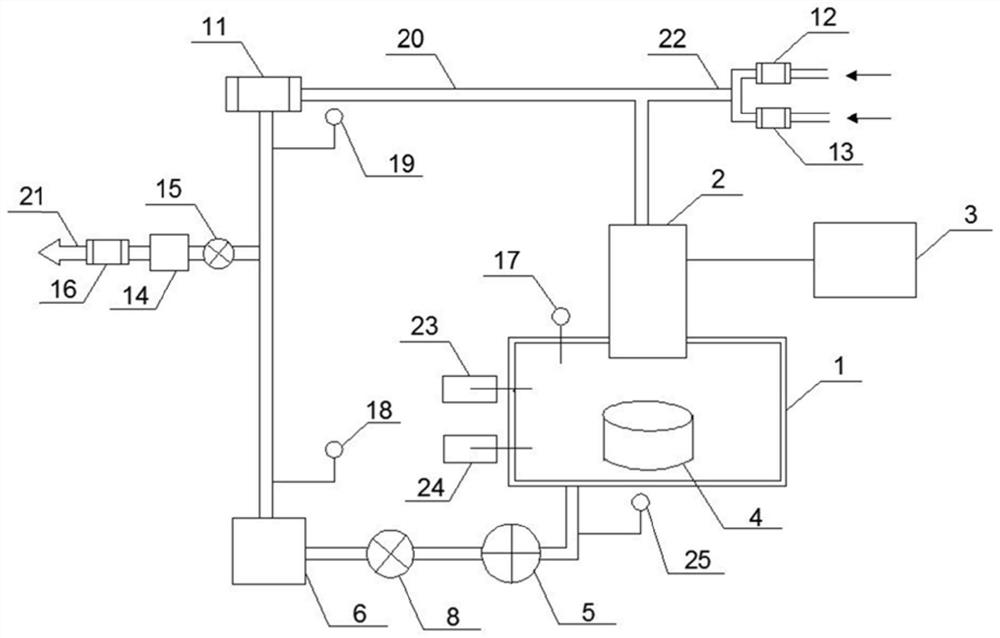

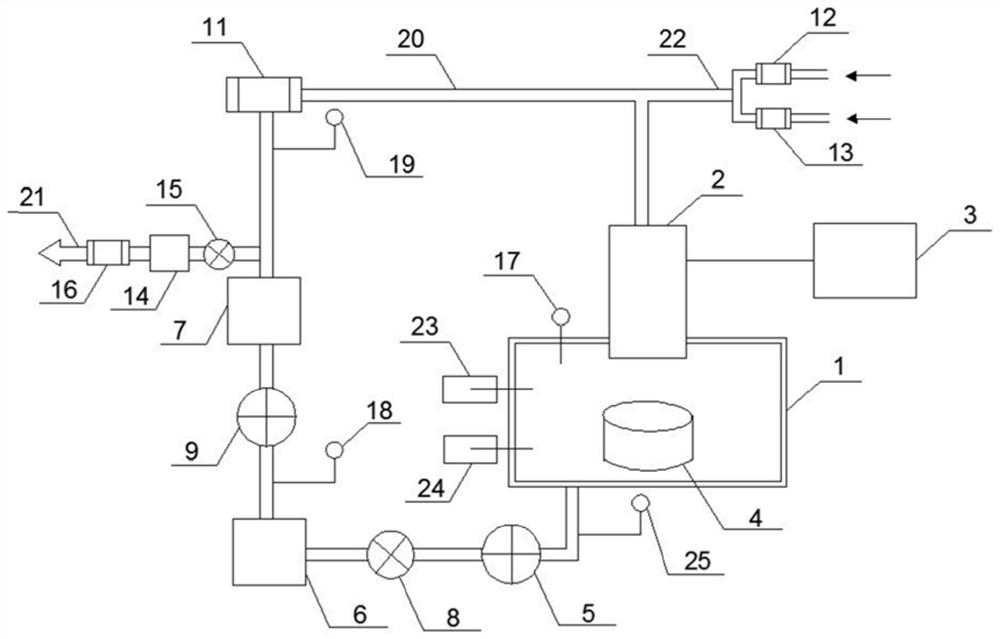

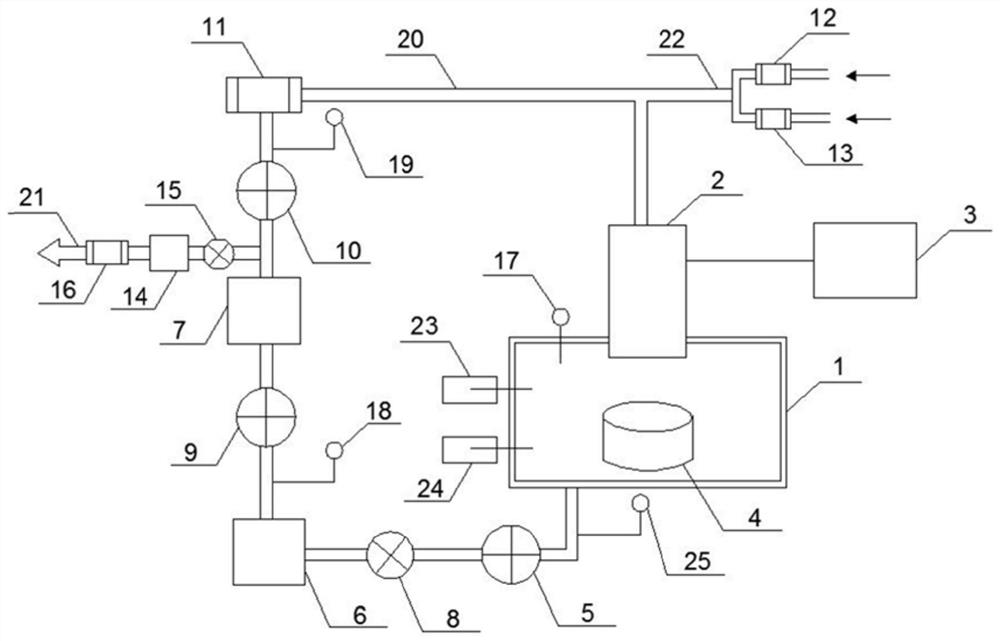

Plasma chemical vapor deposition system and method

A chemical vapor deposition and plasma technology, which is applied in the field of plasma chemical vapor deposition system, can solve the problems of gas waste, unstable deposition atmosphere, and difficulty in avoiding external impurity pollution, etc., to reduce gas cost, overcome large gas consumption, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] The plasma chemical vapor deposition method of the present embodiment comprises the following steps:

[0143] (1) Use a DC plasma torch with a rated power of 10kW as the heat source, Ar as the auxiliary ionized gas, CH 4 and H 2 It is a reaction gas, which forms plasma after entering the plasma torch 2;

[0144] (2) The formed plasma enters the deposition chamber 1 for plasma chemical vapor deposition, wherein the material of the deposition substrate 4 is molybdenum, and the bottom of the deposition substrate 4 is connected with a water cooling device;

[0145] (3) Vacuum pump unit pumps out the tail gas after the reaction is completed from the deposition chamber 1, and cools down and purifies and removes corrosive gases through the first purification equipment 5, the pumping volume is controlled by the first solenoid valve 8, and the deposition chamber is monitored by the first pressure sensor 17 1, so that the pressure of the deposition chamber 1 is controlled at 80...

Embodiment 2

[0151] The plasma chemical vapor deposition method of the present embodiment comprises the following steps:

[0152] (1) Use the inductively coupled high-frequency plasma torch with rated power of 100kW as the heat source, O 2 , Ar is an ionized gas, gaseous SiCl 4 It is a reaction gas, which forms plasma after entering the plasma torch 2;

[0153] (2) The formed plasma enters the deposition chamber 1 for plasma chemical vapor deposition, wherein the material of the deposition substrate 4 is quartz glass, and the bottom of the deposition substrate 4 is connected with a water cooling device;

[0154] (3) The vacuum pump group takes out the tail gas after the reaction is completed from the deposition chamber 1, and cools down through the first purification equipment 5 and purifies and removes corrosive gases, such as chlorine gas, and is controlled by the first electromagnetic valve 8. The pumping volume, the first pressure sensor 17 Monitor the pressure of the deposition cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com