Liquefied natural gas (LNG) gasification device and method of offshore platform type receiving station

An offshore platform and gasification device technology, applied in the field of liquefied natural gas gasification, can solve the problems of easy blockage of seawater pipelines and vaporizers, difficulty in ensuring reliability of seawater pumps, difficulty in ensuring operation reliability, etc., and achieve saving on refrigeration and compression Low power consumption, low ecological impact, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to deepen the understanding of the present invention, the principle of the present invention will be further described below in conjunction with the accompanying drawings.

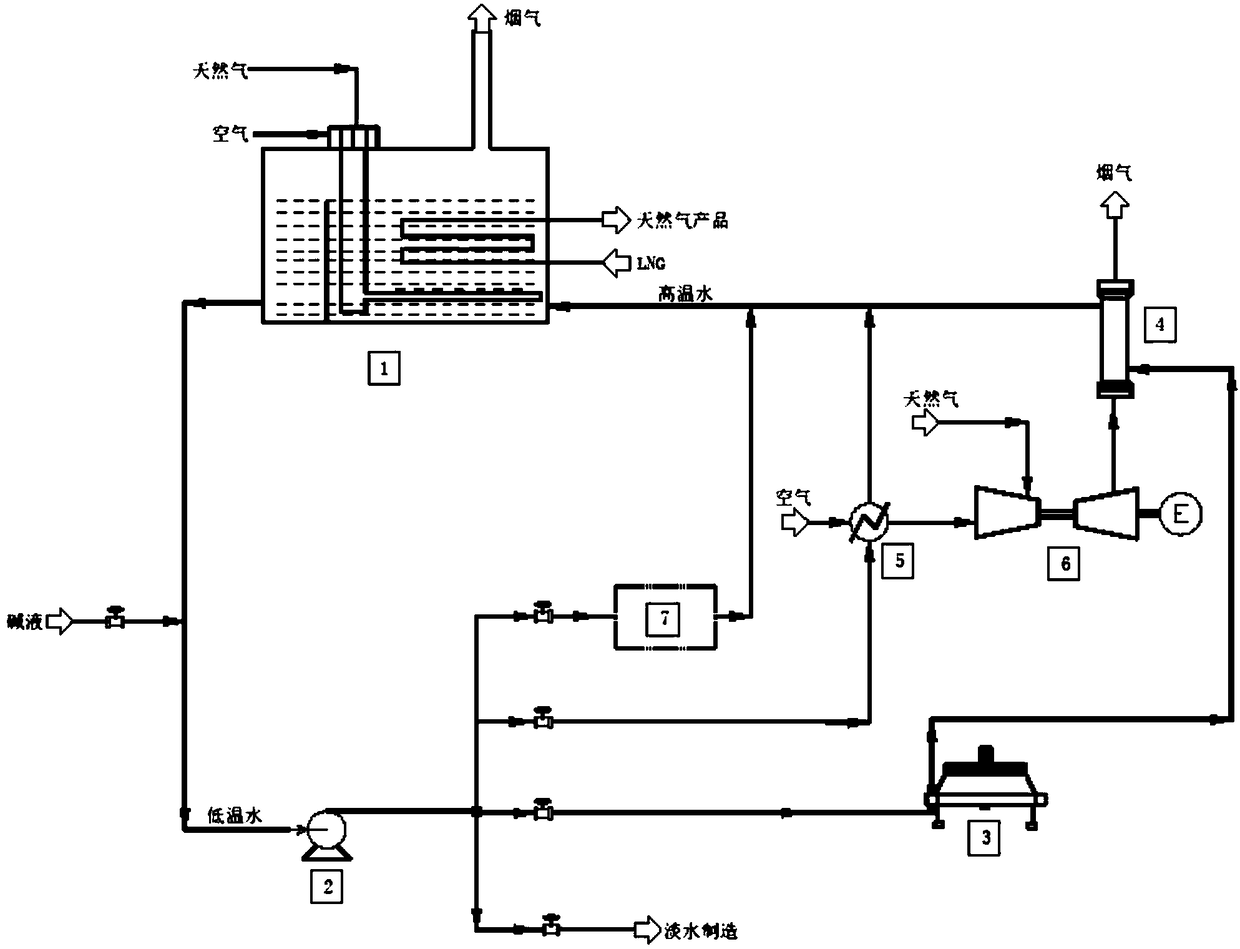

[0040] see first figure 1 , figure 1 It is a schematic diagram of the LNG gasification device of the offshore platform type receiving station of the present invention. It can be seen from the figure that the LNG gasification device of the offshore platform type receiving station of the present invention includes a submerged combustion type gasifier 1, and the gasification of LNG is carried out in the submerged combustion type gasification device. Realized in the evaporator 1, it also includes a circulating pump 2, an air heater 3, a waste heat boiler 4, a cooler 5, a gas generator 6 and a low-temperature water-cooled air-conditioning system 7, and the high-temperature water pipeline output by the waste heat boiler 4 is connected with the The submerged combustion gasifier 1 is connected, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com