Material sterilization method with combination of continuous sterilization and batch sterilization in fermentation of glutamic acid

A sterilization method and technology for fermenting materials, applied in heating and other directions, can solve the problems of large damage to the medium, high energy consumption, scaling of heat exchangers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

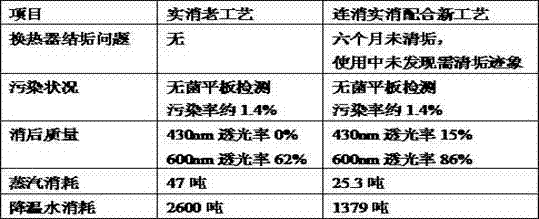

[0022] Embodiment 1 The material sterilization method that Lianshixiao combines in glutamic acid fermentation,

[0023] (1) Fermentation medium composition: corn steep liquor, glucose, phosphoric acid, magnesium sulfate, potassium chloride and soybean meal hydrolyzate (specifically, the weight ratio of each component of the fermentation medium to the total fermentation material is: corn steep liquor 5%, glucose 4-10%, phosphoric acid 0.2-0.4%, magnesium sulfate 0.1-0.2%, potassium chloride 0.3-0.5%, soybean meal hydrolyzate 0.2%);

[0024] (2) Real consumption: mix corn steep liquor, phosphoric acid, and soybean meal hydrolyzate in the fermentation medium, add ingredient water, control the volume to 10% of the total fermentation material volume, put it into the fermentation tank, and heat up to 123°C and keep for 50 minutes;

[0025] (3) Continuous elimination: mix glucose, magnesium sulfate, and potassium chloride, add ingredient water, heat up to 126°C through the continuou...

Embodiment 2

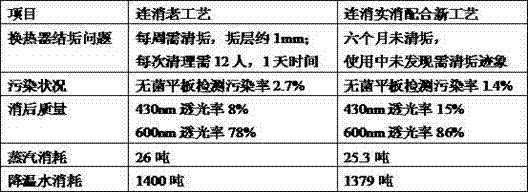

[0027] Embodiment 2 The material sterilization method that Lianshixiao combines in glutamic acid fermentation,

[0028] 1. Composition of fermentation medium:

[0029] Corn steep liquor: (5%), glucose (4%--10%), phosphoric acid (0.2-0.4%), magnesium sulfate (0.1-0.2%), potassium chloride (0.3%--0.5%), soybean meal hydrolyzate (0.2%);

[0030] 2. Mix corn steep liquor, phosphoric acid, and soybean meal hydrolyzate together, and put them directly into the tank to be sterilized, and add ingredient water to make the volume reach 10% of the total volume.

[0031] 3. The fermenter (including the 2-step mixture) is heated from the bottom by steam, so that the temperature reaches 122°C--125°C and keeps for 40-60 minutes.

[0032] 4. Mix other components except the medium material in step 2 together, and add batching water to make up the volume, raise the temperature to 125°C-128°C through the continuous elimination device, maintain the temperature in the tank for 8-10 minutes, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com