An environmentally friendly intermittent multifunctional biomass pyrolysis equipment

A biomass pyrolysis and intermittent technology, applied in the direction of biofuel, indirect heating dry distillation, special form of dry distillation, etc., to achieve the effect of overcoming the little use value, improving safety performance and environmental protection, and operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

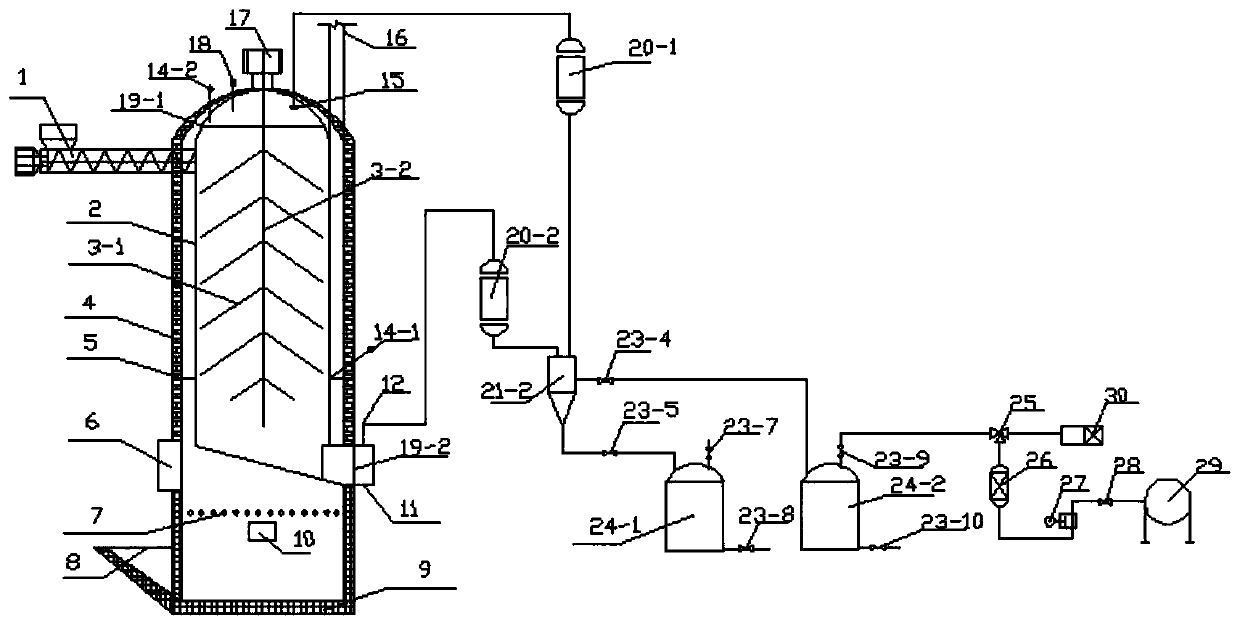

Embodiment 1

[0047] An environmentally friendly intermittent multifunctional biomass pyrolysis equipment (single oil-water separator), including screw feeder 1, cracking furnace 2, stirring horizontal bar 3-1, stirring vertical bar 3-2, furnace outer wall 4, cracking furnace Fixing part 5, furnace mouth 6, fire grate 7, shielding plate 8, furnace base 9, blower inlet 10, discharge port 11, lower exhaust port 12, buffer tank 13, lower temperature measuring point 14-1, upper measuring point Temperature point 14-2, upper exhaust port 15, chimney 16, stirring motor 17, pressure gauge 18, upper intercepting net 19-1, lower intercepting net 19-2, upper condenser 20-1, lower condenser 20-2 , lower oil-water separator 21-2, four-way ball valve 22, stop valve 23-1~23-10, liquid storage tank 24-1, gas storage tank 24-2, three-way ball valve 25, drying tank 26, compressor 27 , a check valve 28, a spherical storage tank 29, a vacuum pump 30, and connected pipelines, characterized in that: the inlet of...

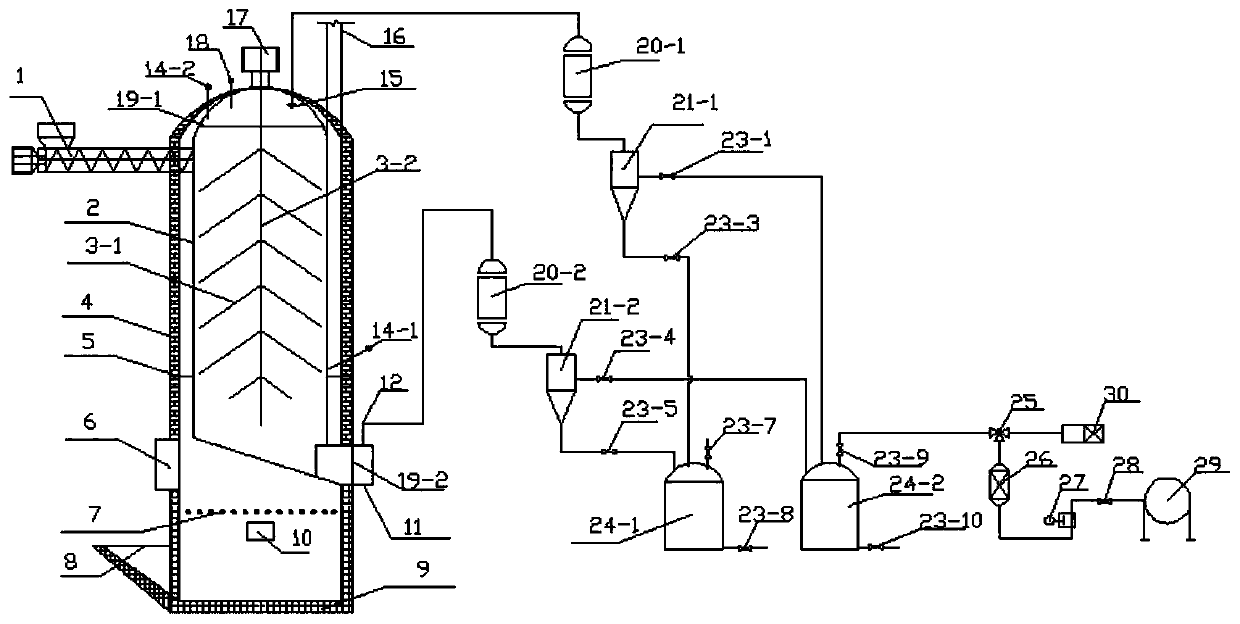

Embodiment 2

[0057]An environmentally friendly intermittent multifunctional biomass pyrolysis equipment (double oil-water separator), including screw feeder 1, cracking furnace 2, stirring horizontal bar 3-1, stirring vertical bar 3-2, furnace outer wall 4, cracking furnace Fixing part 5, furnace mouth 6, fire grate 7, shielding plate 8, furnace base 9, blower inlet 10, discharge port 11, lower exhaust port 12, buffer tank 13, lower temperature measuring point 14-1, upper measuring point Temperature point 14-2, upper exhaust port 15, chimney 16, stirring motor 17, pressure gauge 18, upper intercepting net 19-1, lower intercepting net 19-2, upper condenser 20-1, lower condenser 20-2 , upper oil-water separator 21-1, lower oil-water separator 21-2, stop valve 23-1~23-10, liquid storage tank 24-1, gas storage tank 24-2, three-way ball valve 25, drying tank 26, Compressor 27, check valve 28, spherical storage tank 29, vacuum pump 30, and connected pipelines, characterized in that: the inlet of...

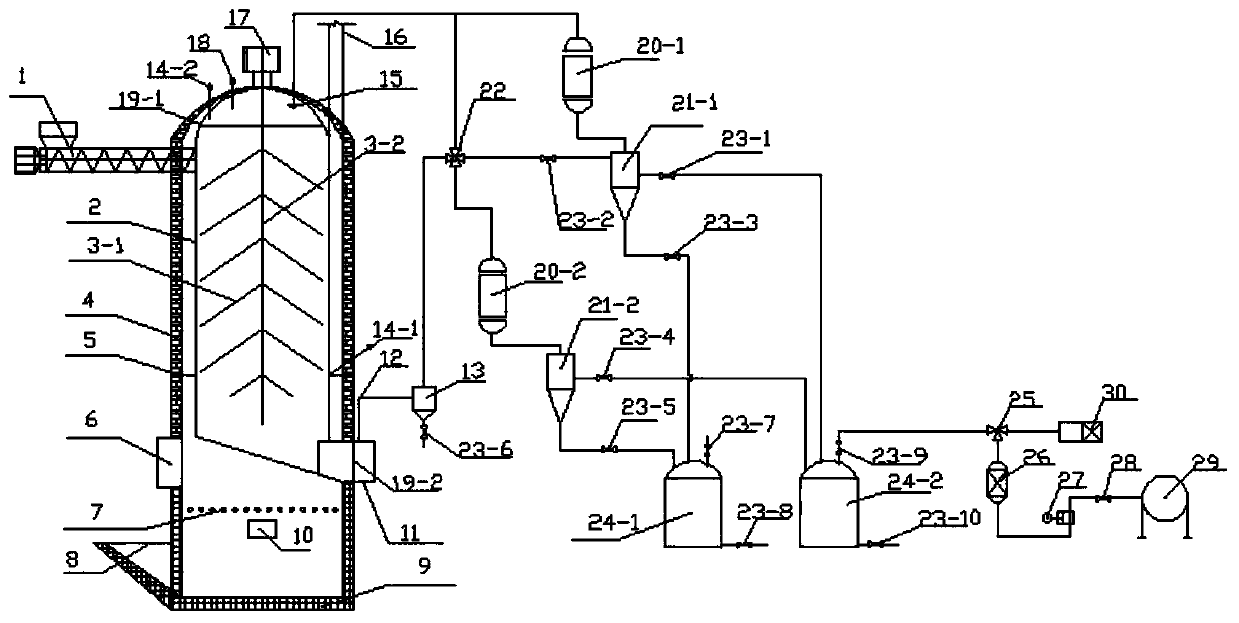

Embodiment 3

[0066] An environmentally friendly intermittent multifunctional biomass pyrolysis equipment (a cracking device with a four-barrel ball valve to control the cooling system), including a screw feeder 1, a cracking furnace 2, a stirring horizontal bar 3-1, a stirring vertical bar 3-2, Furnace outer wall 4, cracking furnace fixture 5, furnace mouth 6, fire grate 7, shielding plate 8, furnace base 9, blower inlet 10, discharge port 11, lower exhaust port 12, buffer tank 13, lower temperature measuring point 14-1, upper temperature measuring point 14-2, upper exhaust port 15, chimney 16, stirring motor 17, pressure gauge 18, upper intercepting net 19-1, lower intercepting net 19-2, upper condenser 20-1, Lower condenser 20-2, upper oil-water separator 21-1, lower oil-water separator 21-2, four-way ball valve 22, stop valve 23-1~23-10, liquid storage tank 24-1, gas storage tank 24- 2. Three-way ball valve 25, drying tank 26, compressor 27, check valve 28, spherical storage tank 29, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com