Pressure control method and pressure control device of silicon steel magnesium oxide coating

A technology of pressure control and magnesium oxide, which is applied to the device and coating of the surface coating liquid, can solve the problems that the pressure control is difficult to stabilize, realize the micro-control of the force, control the shock deviation of the pressure value, and pressure fluctuations, etc., to avoid The effect of large pressure fluctuations, uniform beating frequency, and reduced variation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiment of the present invention provides a pressure control method and device for magnesium oxide coating on silicon steel, which solves the problem that in the prior art, it is difficult to realize the micro-control of the force stably during pressure control, and it is easy to cause the control pressure value to oscillate around the set value And the technical problem that the deviation cannot be reduced reduces the range of pressure value change after the closed-loop PID pressure control, and the beating frequency is uniform, avoiding the large pressure fluctuation caused by the properties of the equipment itself when the screw motor adjusts the pressure, and improving the quality of the coated magnesium oxide. The thickness uniformity of the film improves the quality of the magnesium oxide coating on silicon steel.

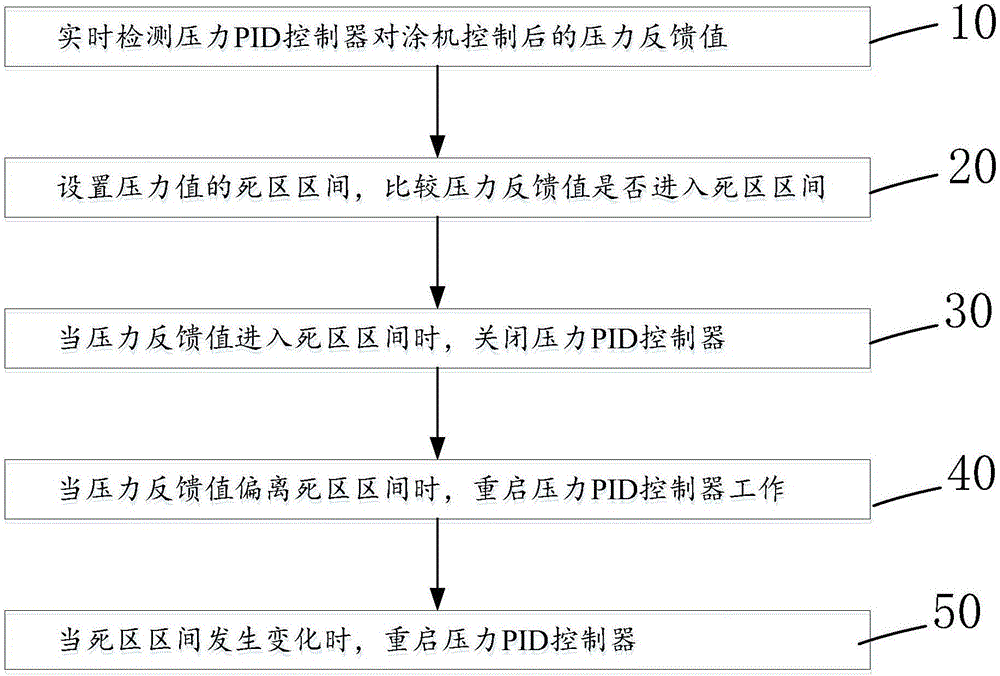

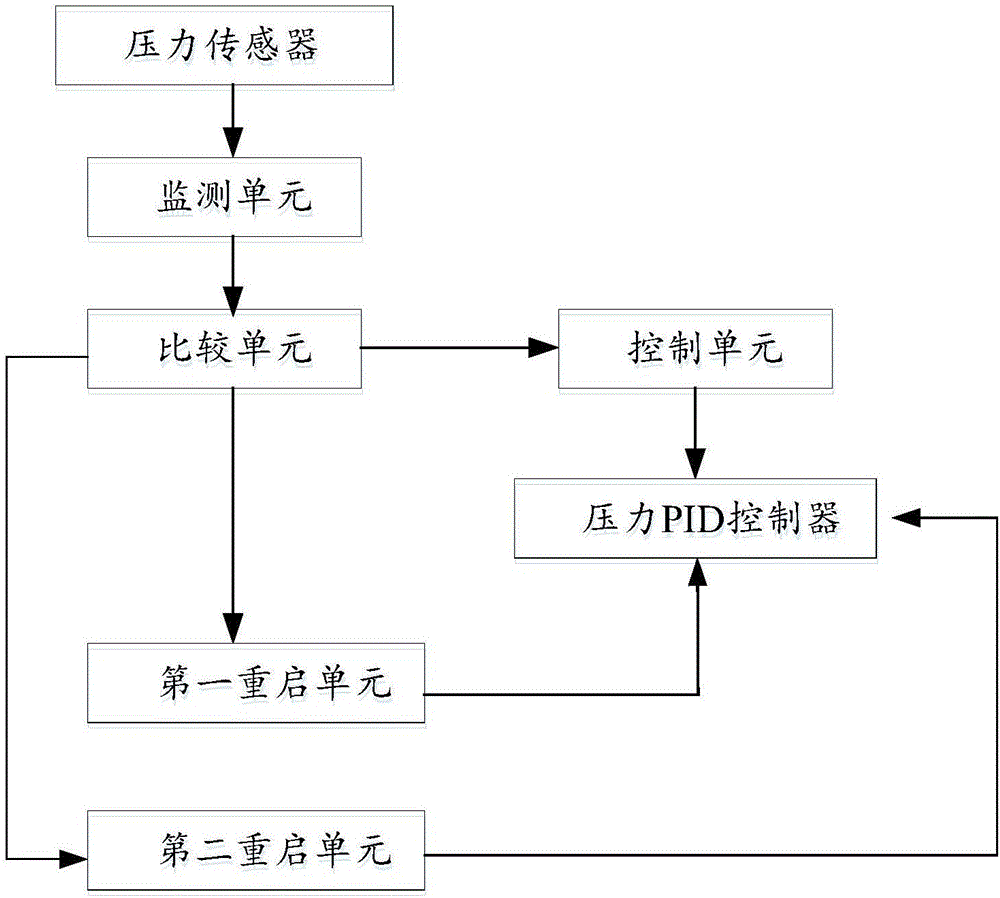

[0027] see figure 1 , the embodiment of the present invention provides a pressure control method for silicon steel magnesia coating, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com