Sulfur tolerant catalyzing process for preparing low carbon alcohol from synthesis gas and co-producing natural gas

A low-carbon alcohol and synthesis gas technology, applied in the preparation of hydroxyl compounds, organic compounds, petroleum industry, etc., to achieve the effects of increased production costs, good industrial prospects, and improved carbon utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

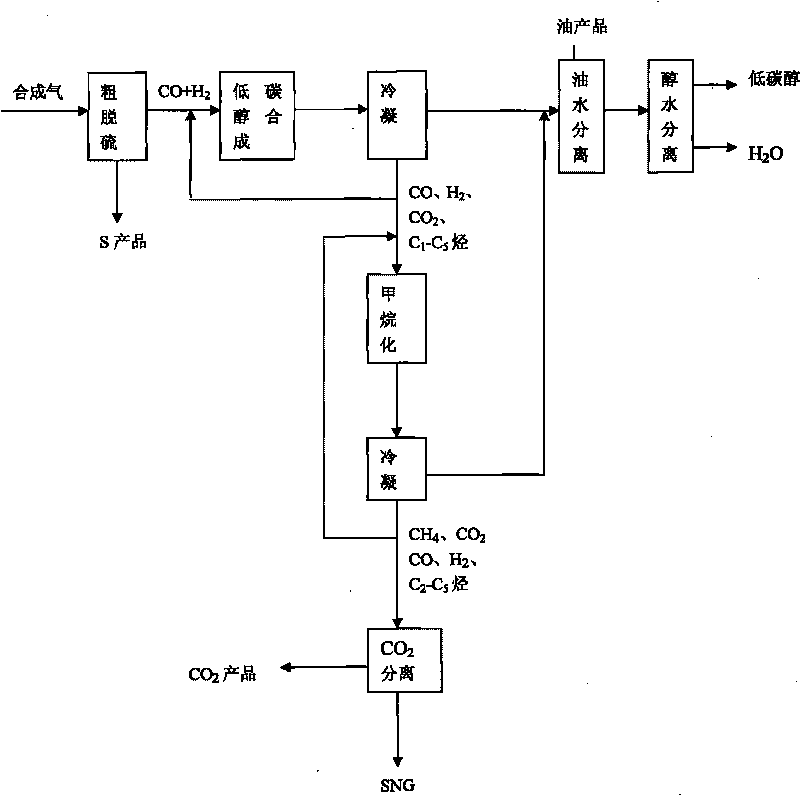

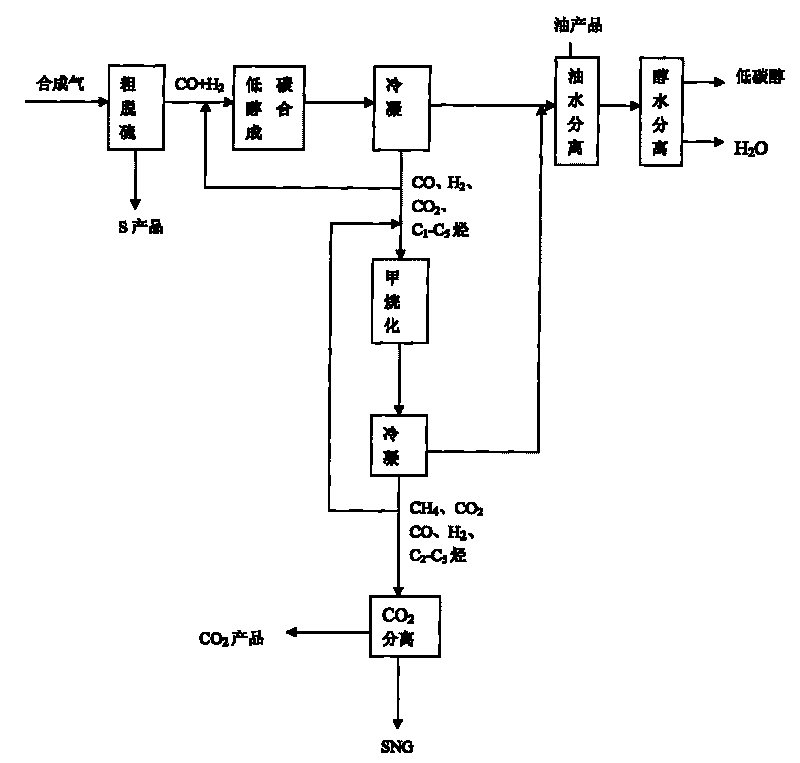

[0031] This embodiment adopts figure 1 The process flow shown. Coal-based synthesis gas (with a hydrogen-to-carbon molar ratio of 2) enters the crude desulfurization unit and adopts the tannin extraction method for crude desulfurization to obtain a synthesis gas with a sulfur content of less than 100ppm. After mixing with the tail gas recycled to the synthesis reaction of low-carbon alcohols, it enters the synthesis of low-carbon alcohols Device, at a reaction temperature of 300°C, a reaction pressure of 6MPa, and a space velocity of 3000h -1 (V / V), DOW Corporation MoS 2 -React under the action of M-K catalyst, the product enters the condensing device through the pipeline, and condenses at a temperature of 0°C and a pressure of 6MPa to obtain the liquid phase of alcohol, water and oil, CO, H 2 , CO 2 、C 1 -C 5 Exhaust gas mixture composed of hydrocarbons. The alcohol-water-oil liquid phase is mixed with the alcohol-water-oil liquid phase obtained by the condensation of t...

Embodiment 2

[0033] This embodiment adopts figure 1 The process flow shown. Coal-based synthesis gas (hydrogen-to-carbon molar ratio is 1.5) enters the crude desulfurization unit and uses the ADA method for crude desulfurization to obtain a synthesis gas with a sulfur content of less than 100ppm. After mixing with the tail gas recycled to the synthesis reaction of low-carbon alcohols, it enters the low-carbon alcohol synthesis unit , at a reaction temperature of 320°C, a reaction pressure of 8MPa, and a space velocity of 5000h -1 (V / V), DOW Corporation MoS 2 -Reaction under the action of M-K catalyst, the product enters the condensing device through the pipeline, and condenses at a temperature of 4°C and a pressure of 8MPa to obtain the liquid phase of alcohol, water and oil, CO, H 2 , CO 2 、C 1 -C 5 Exhaust gas mixture composed of hydrocarbons. The alcohol-water-oil liquid phase is mixed with the alcohol-water-oil liquid phase obtained by the condensation of the methanation reaction...

Embodiment 3

[0035] This embodiment adopts figure 1 The process flow shown. Coal-based synthesis gas (hydrogen-to-carbon molar ratio is 1) enters the crude desulfurization unit and uses the MSQ method for rough desulfurization to obtain synthesis gas with a sulfur content of less than 100ppm. After mixing with the tail gas recycled to the synthesis reaction of low-carbon alcohols, it enters the low-carbon alcohol synthesis unit. At a reaction temperature of 340°C, a reaction pressure of 10MPa, and a space velocity of 6000h -1 (V / V), DOW Corporation MoS 2 -Reaction under the action of M-K catalyst, the product enters the condensing device through the pipeline, and condenses at a temperature of 5°C and a pressure of 10MPa to obtain the liquid phase of alcohol, water and oil, CO, H 2 , CO 2 、C 1 -C 5 Exhaust gas mixture composed of hydrocarbons. The liquid phase of alcohol water oil is mixed with the alcohol water oil liquid phase obtained by condensation of the methanation reaction pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com