Method for producing butanol and butanedioic acid by fermentation

A technology for the production of butanol and succinic acid, which is applied in the field of fermentation to produce butanol and succinic acid, can solve the problems of increasing fermentation costs and achieve the effects of improving carbon source utilization, reducing fermentation costs, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the screening and effect verification of butanol and succinic acid produced by fermentation of the present invention

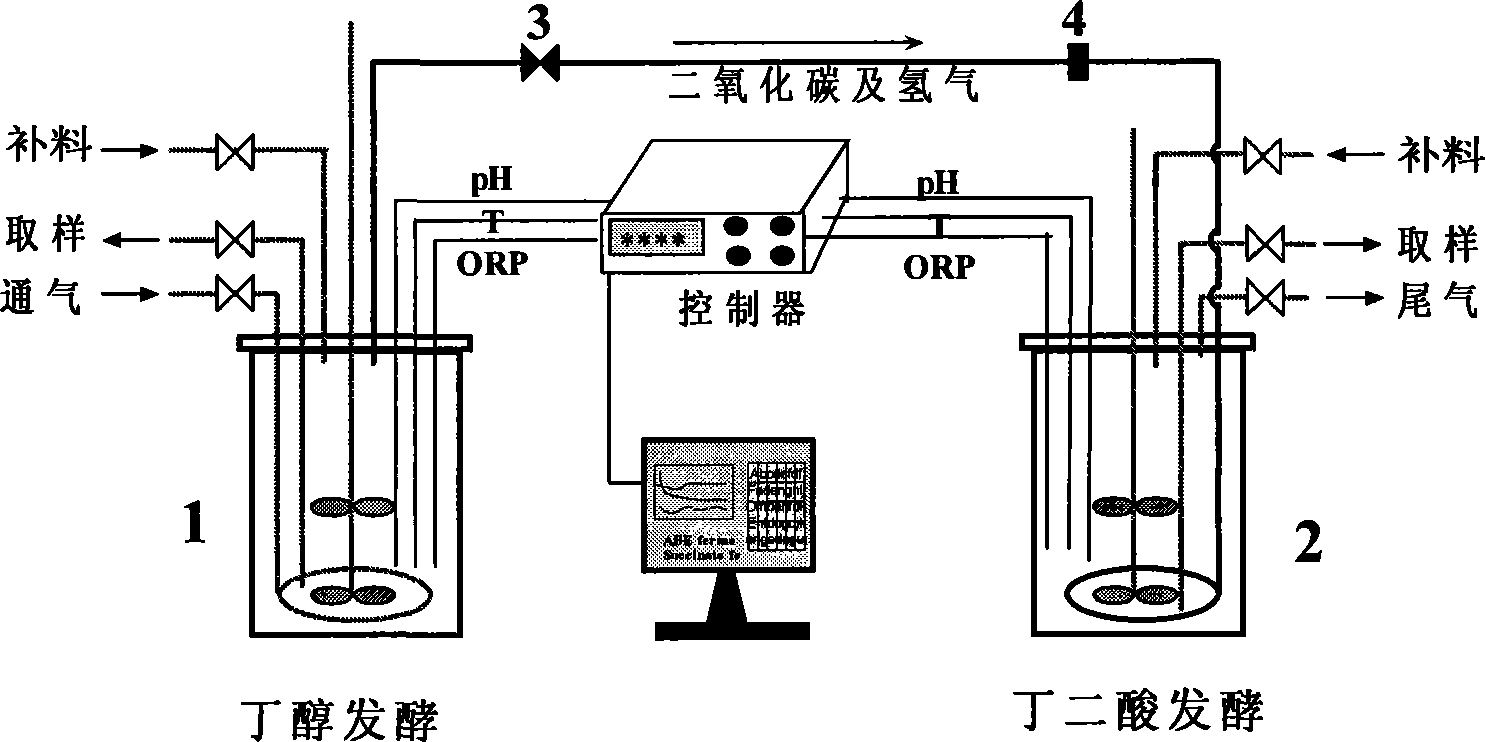

[0037] Fermentative production of butanol and succinic acid of the present invention are respectively used to produce CO 2 Microbial fermentation produces butanol, using available CO 2 Microbial fermentation produces succinic acid; the schematic diagram of its production equipment is shown in figure 1 as shown, figure 1 Among them, 1 is a butanol fermentation tank; 2 is a succinic acid fermentation tank; 3 is a valve; 4 is a gas filter; the tail gas of the butanol fermentation tank 1 passes through the valve 3 and the gas filter 4 into the succinic acid fermentation tank 2 .

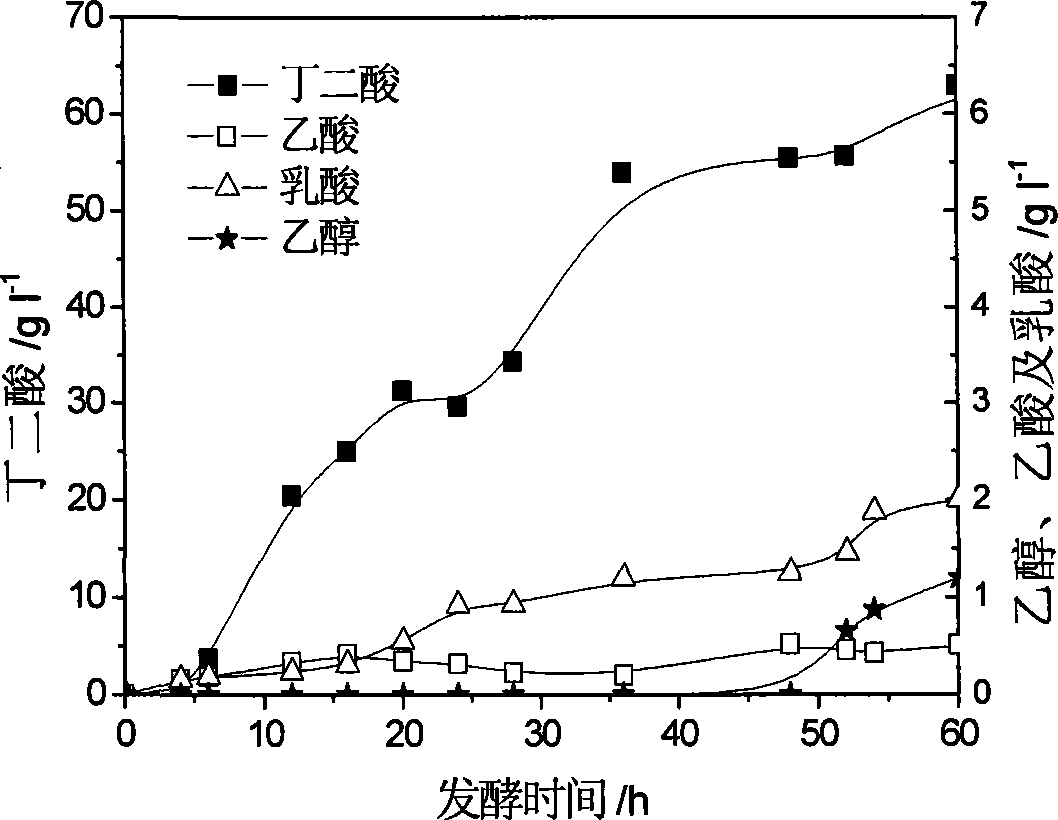

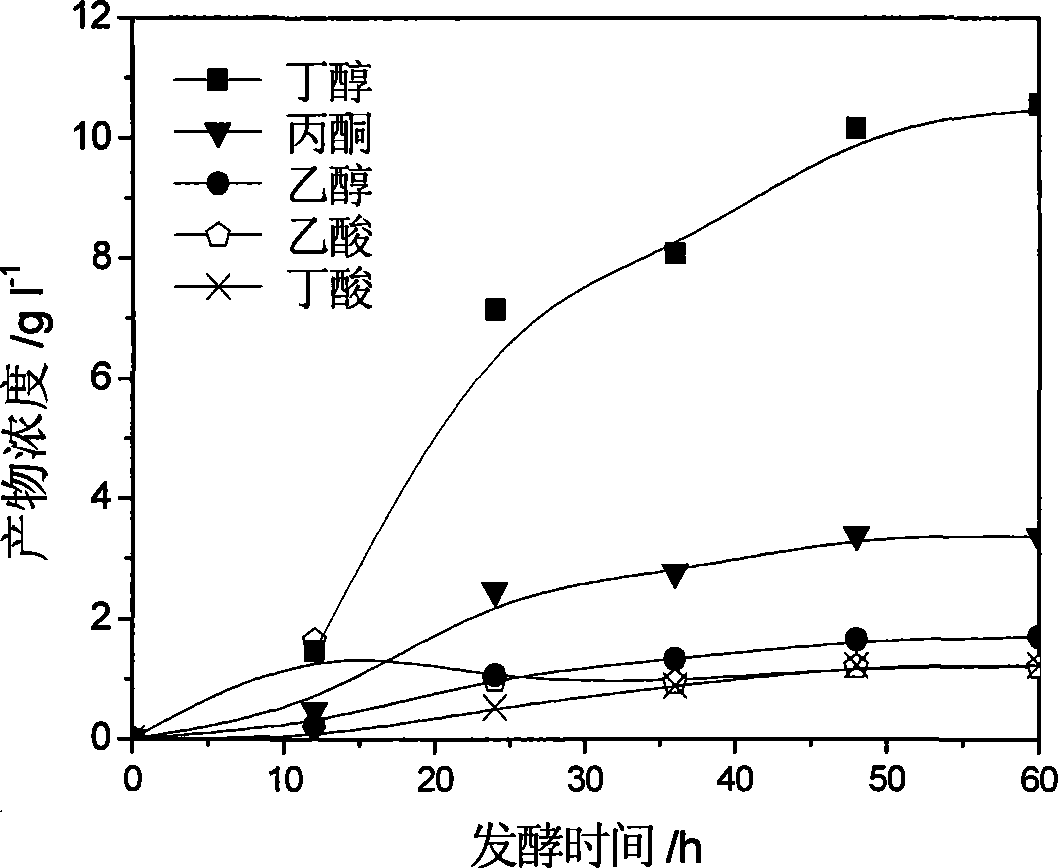

[0038] The following examples carry out butanol fermentation with Clostridium acetobutylicum (Clostridium acetobutylicum) SB-1 (China General Microorganism Culture Collection and Management Center, CGMCC No.2287), and carry out with succinic acid Actinobacillus (A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com