Solar dryer

A solar drying and drying tube technology, applied in solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problem of low solar radiation energy flow density, widen the utilization field, facilitate rapid heat storage and release heat, Guarantee the effect of energy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

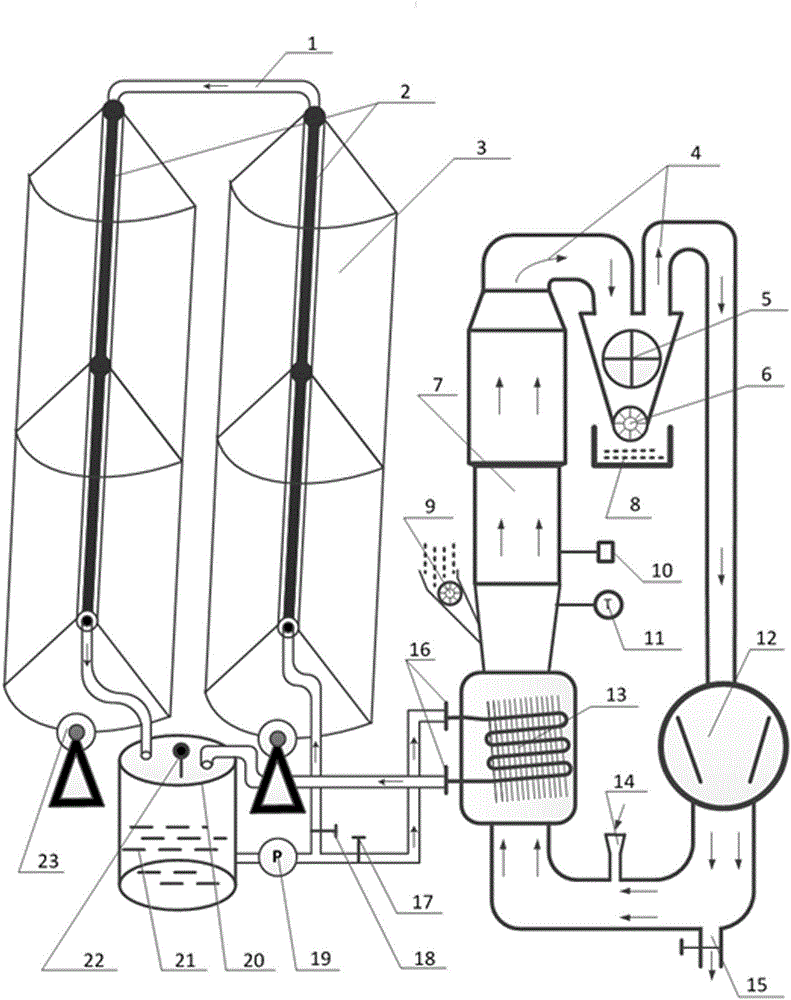

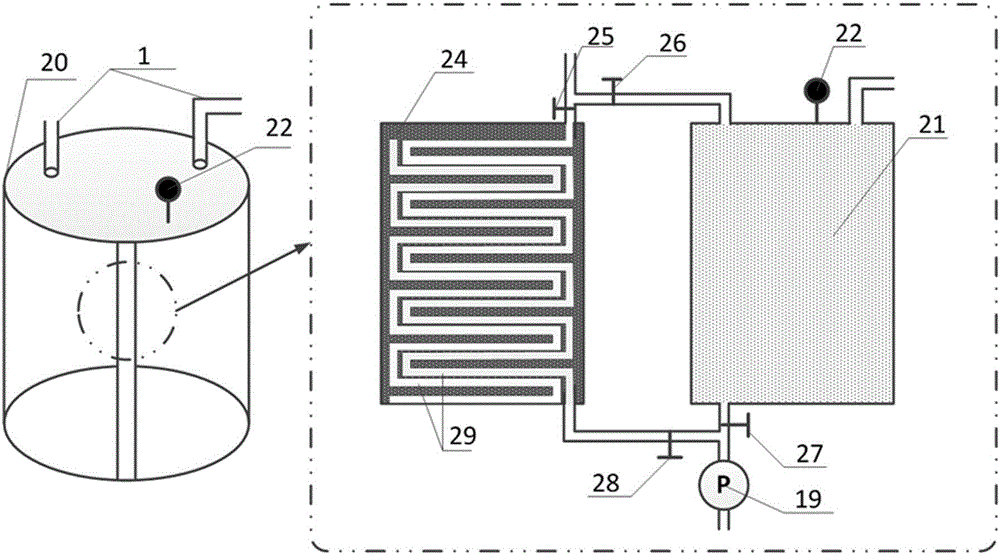

[0021] Such as figure 1 As shown, the structural representation of the solar drying device of the present invention is provided, which includes an oil tank 20, a circulating oil pump 19, a vacuum heat collecting tube 2, a reflective condenser mirror 3, a liquid-gas heat exchanger 13 and a drying device. The oil 21 and the circulating oil pump 19 are arranged on the outlet of the oil tank 20 for driving the heat transfer oil to circulate. The outlet of the circulating oil pump 19 is divided into two paths, one path is communicated with the vacuum heat collecting pipe 2 through the insulating oil pipe, and the other path is communicated with the liquid-gas heat exchanger 13 through the insulating oil pipe; the first valve 17 and the second valve 18 are respectively arranged in the oil tank 20 On the insulating oil pipe between the vacuum heat collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com