Internal absorption type solar drier

A solar energy and absorption technology, applied in drying chamber/container, partial agitation dryer, drying gas arrangement, etc., can solve the problems of industrialization difficulties, high cost of forage, and inconspicuous economic benefits, and achieve compact structure and high heat output The effect of high utilization rate and device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

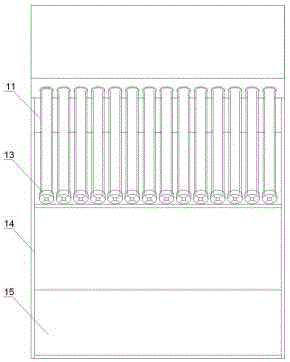

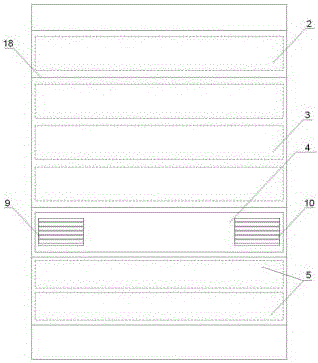

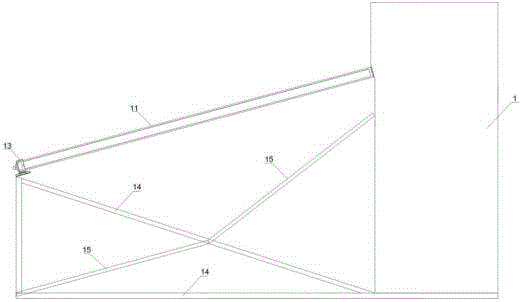

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0030] Such as Figure 1-5 As shown, the present invention mainly includes a solar heat collecting device, a drying box 1 and a control system. The inside of the drying box 1 is sequentially provided with a layer of phase change energy storage drawer 2, a three-layer material drying drawer 3, and a cross-flow waste heat The recovery exchanger 4 and the two-layer adsorption dehumidification drawer 5, and a partition 6 is set between the rear inner wall of the drying box 1, so that the partition 6 and the inner wall of the drying box 1 form a preheated air flow channel 7; the bottom of the drying box 1 is set Circulation fan 8; thermal insulation material is pasted on the inner wall of drying box 1 to form thermal insulation layer 16;

[0031]The bottoms of phase change energy storage drawer 2, material drying drawer 3 and adsorption dehumidifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com