Mixed-type sludge solar dryer

A technology of solar energy and dryer, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of lagging sludge treatment and disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

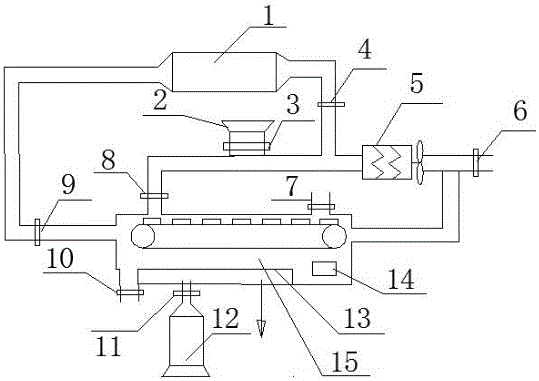

[0011] The present invention is realized through the following technical solutions: when the dryer starts to operate, a large amount of flowing air is needed, the air valves (4) and (6) are opened, the fan (5) is started, and the air circulation is accelerated. The high-temperature hot air is turned on, the air valve (9) is opened, and the high-temperature hot air enters the drying chamber (15) for drying operation. The wet sludge enters from the feed port (7), and after being dried in the drying chamber (15), it is discharged from the conveyor belt. The material port (10) is discharged. At the same time, open the air valves (3) and (8) to discharge the moisture from the exhaust port (2). Through the setting of the air valve, a part of the air flow can be circulated in the drying room and the pipeline, thereby reducing energy consumption.

[0012] Under the conveyor belt, there are up and down staggered guide rails. The sludge moves on the conveyor belt in a wave shape, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com