Milling and drying machine and powder making system

An all-in-one machine and powder grinding technology, applied in the directions of drying gas arrangement, dryer, drying, etc., can solve the problems of low production efficiency, high production cost, large floor space, etc., and achieve high production efficiency and fewer operators. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

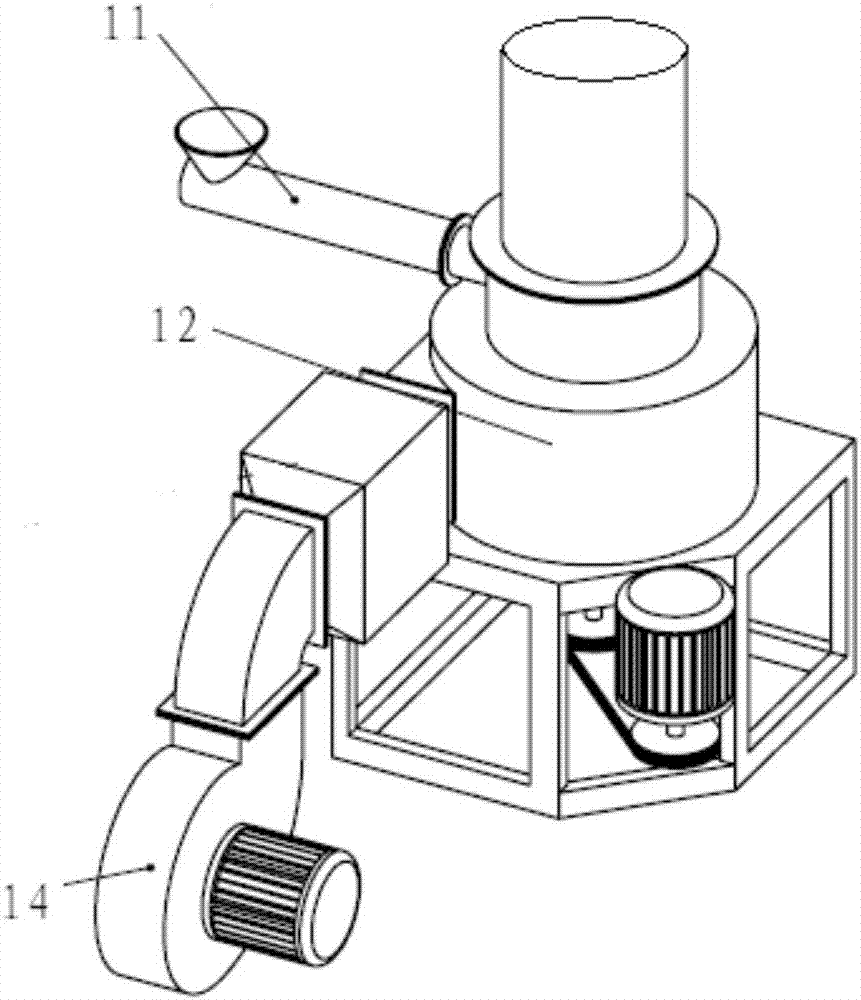

Embodiment 1

[0045] Embodiment 1 discloses a milling and drying integrated machine, comprising: a feeder; a milling and drying chamber, which communicates with the feeder; a grinding roller, which is arranged in the milling and drying chamber and located The bottom of the communication port between the milling drying chamber and the feeder; the hot air blower, which communicates with the milling drying chamber, is used to deliver hot air to the milling drying chamber, and the communication port between the hot air blower and the milling drying chamber is located in the Below the grinding roller.

[0046] During use, the feeder transports the material to the milling and drying chamber, and the grinding roller rubs and breaks the material to obtain whiskers, and the hot air blower supplies hot air to the milling and drying chamber to dry the whiskers.

Embodiment 2

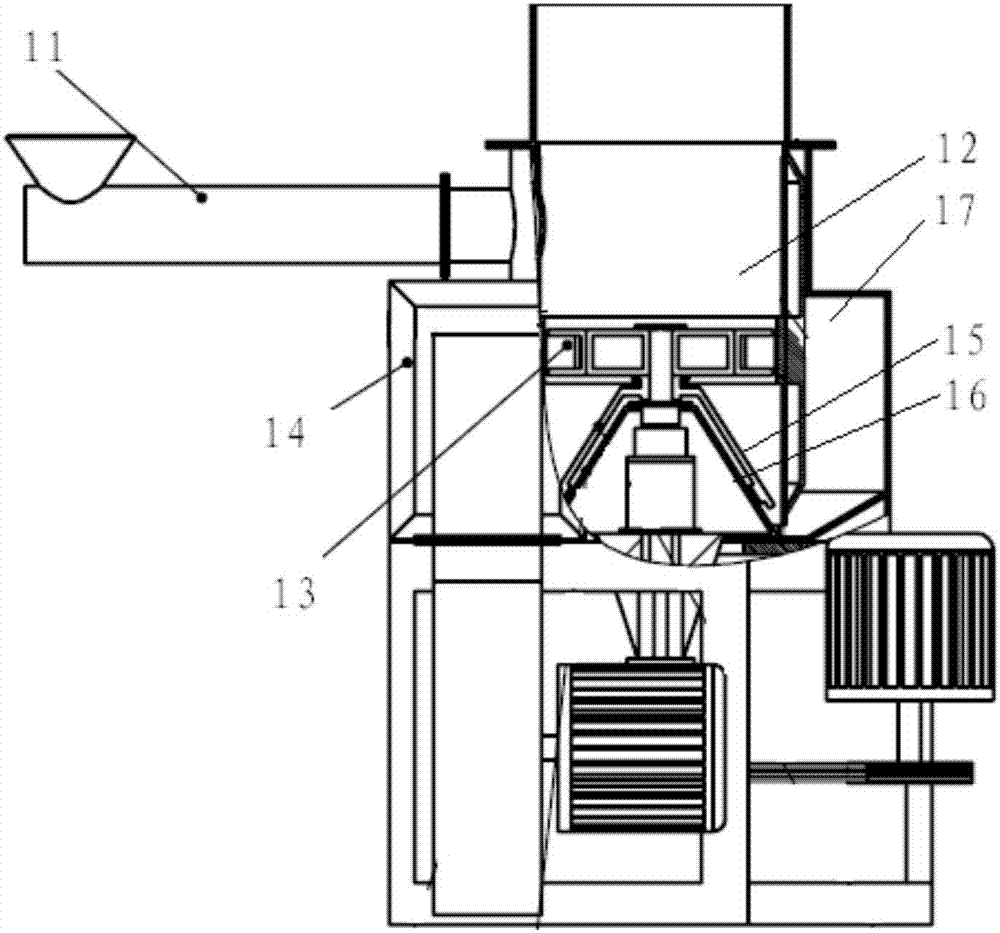

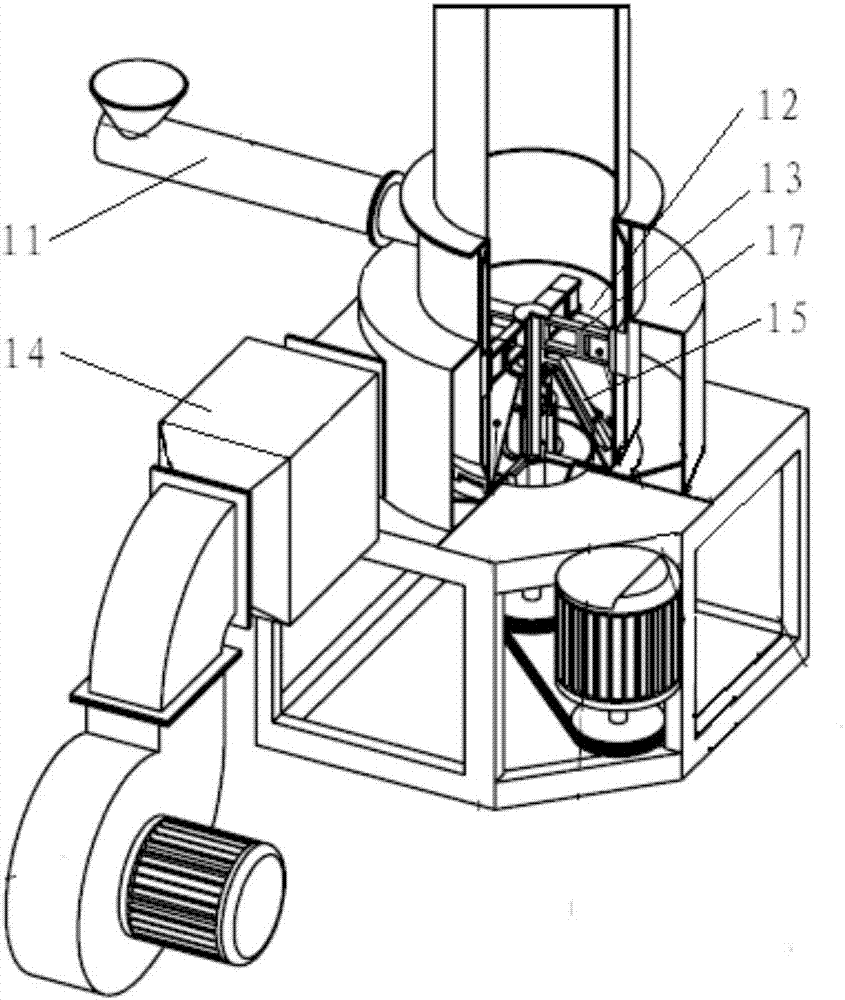

[0048] The difference between the second embodiment and the first embodiment is that the integrated grinding and drying machine in the second embodiment also includes an agitator, the agitator is arranged in the grinding and drying chamber, and is located under the grinding roller, and the agitator is used to stir the whiskers .

[0049] The agitator can drive the hot air entering the grinding and drying chamber to generate a high-speed rotating air flow, and then form a stable fluidized bed in the grinding and drying chamber below the grinding roller, avoiding local sticking of materials; secondly, the agitator is set on the grinding roller At the bottom, during the high-speed rotation process, the grinding roller continuously kneads the bulk material, and the material is crushed into fibrous powder whiskers, thereby increasing the surface area of the material and strengthening the mass-heat exchange of the material. Then the agitator is continuously stirred, so that the dr...

Embodiment 3

[0053] The difference between the third embodiment and the second embodiment is that the integrated grinding and drying machine in the third embodiment also includes a cone structure. The first end of the cone is fixed at the bottom of the milling and drying chamber, and the second end is used to install the agitator, and the volume of the cone structure gradually decreases from the first end to the second end.

[0054] The setting of the cone structure makes the flow cross-sectional area of the hot air in the powder milling and drying chamber continuously increase from bottom to top, the air velocity at the bottom is relatively large, and the air velocity at the upper part is relatively small, thus ensuring that the large particle whiskers at the lower part are in fluidization At the same time, the small particle whiskers on the upper part are also in a fluidized state; and installing the agitator on the cone structure can also shorten the length of the arm part of the agita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com