Solar pond composite drying system

A drying system and solar pond technology, applied in the field of solar energy storage utilization devices, can solve the problems of large impact of weather changes, etc., and achieve the effects of large heat storage capacity, wide application range and remarkable drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

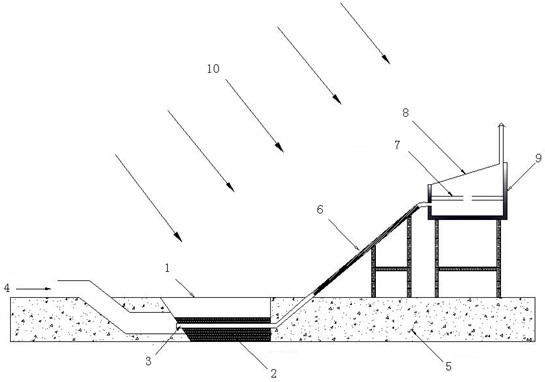

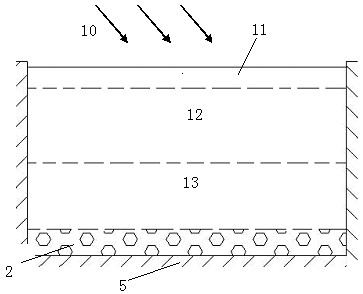

[0014] Such as figure 1 The solar pool-collector composite drying system shown. Considering the thermal insulation and construction cost of the solar pond, the solar pond is built below the surface; the drying chamber 9 is built 3 meters above the ground, and the inside of the drying chamber 9 is equipped with a mesh partition 7 for putting materials. It is a transparent glass plate 8 with the same inclination angle as the local latitude. If the material needs to be protected from direct sunlight, the glass plate can be covered with a layer of shade net; a solar collector 6 is installed between the solar pool 1 and the drying room 9, To make full use of solar energy. One end of the heating heat exchange copper pipe 3 is connected to the air duct 4 and the other end is connected to the solar heat collector 6 .

[0015] The air dried by the desiccant e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com