Flat plate integral type solar drier

A flat-panel solar energy, integrated technology, applied in the direction of solar thermal power generation, solar thermal devices, dry gas arrangement, etc., can solve the problems of product quality decline, high cost, low solar energy utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

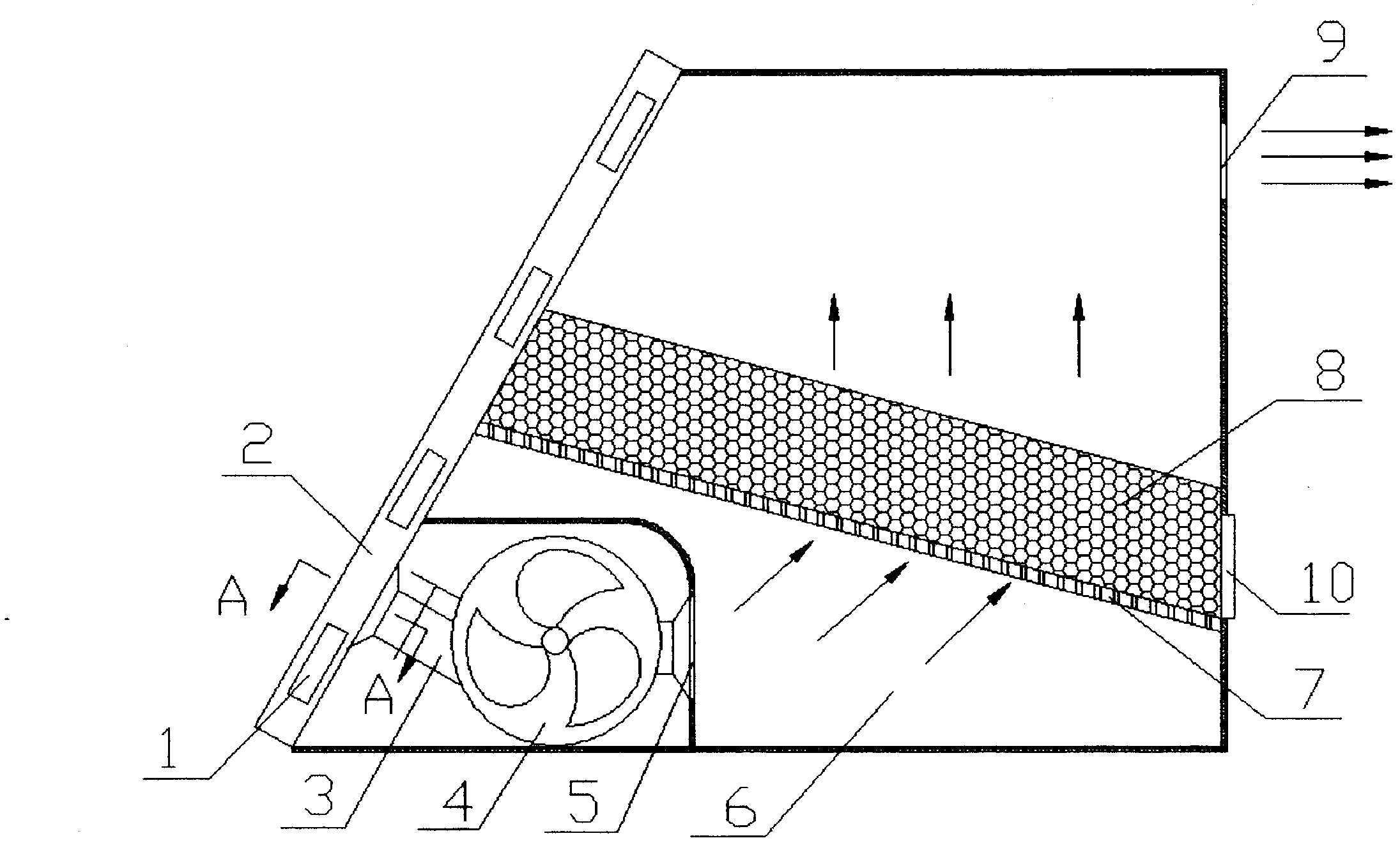

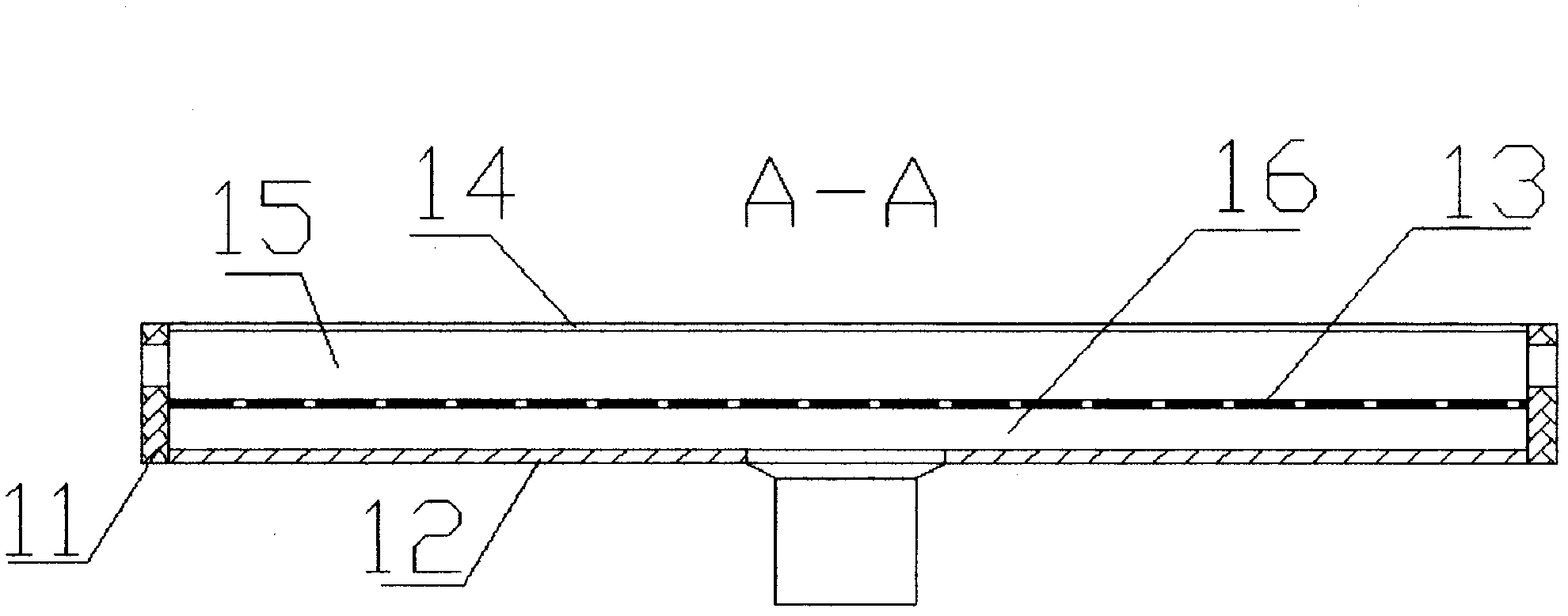

[0012] The device uses a porous flat solar air heat collector 2 as a heat source. After the fan 4 is started, the hot air is extracted from the porous flat solar air heat collector 2 and sent into the drying bin to dry the goods. The outside air enters the collector front chamber 15 from the air inlets 2 evenly distributed on both sides of the porous flat solar air heat collector 2, and enters the collector rear chamber 16 after passing through the small holes on the porous heat collector plate 13 to absorb heat. Finally, it enters the fan 4 from the outlet of the heat collector through the air outlet valve of the heat collector. The hot air first enters the pressure equalization chamber 6 of the drying bin through the action of the fan 4, and then passes through the perforated sieve 7 and the dry matter 8, and the moisture is discharged from the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com