Device and method for recovering bottom slag heat of circulating fluidized bed boiler

A heat recovery device, a technology of circulating fluidized bed, which is applied in the directions of fluidized bed combustion equipment, combustion method, lighting and heating equipment, etc., can solve the problems of reducing boiler thermal efficiency, boiler heat loss, and difficulty in enlarging the drum slag cooler. , to reduce physical heat loss and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

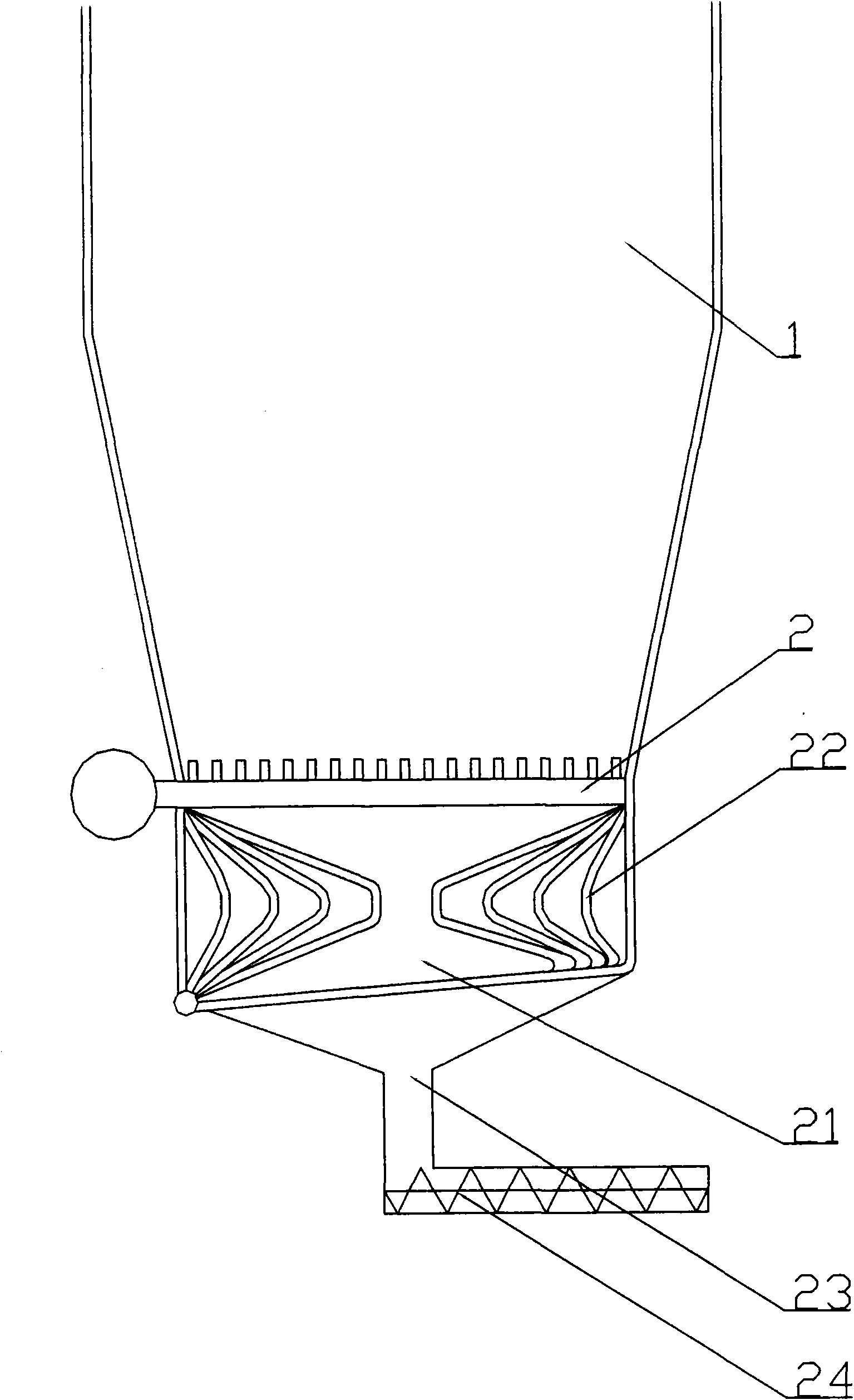

[0039] Such as figure 1 Shown is a schematic structural view of Embodiment 1 of a circulating fluidized bed boiler bottom slag heat recovery device of the present invention, wherein: circulating fluidized bed boiler furnace 1, air distribution pipe 2, bottom slag heat recovery chamber 21, cold slag The heat exchange tube 22 on the heat exchange surface, the slag outlet 23, and the slag remover 24.

[0040] The bed surface at the bottom of the furnace 1 of the circulating fluidized bed boiler is all air distribution pipes 2 with hoods, and there is a gap between the two air distribution pipes to allow the passage of bottom slag particles. A bottom slag heat recovery chamber 21 is arranged below the air distribution pipe 2 , and the bottom slag heat recovery chamber 21 is directly communicated with the boiler furnace 1 through the gap between the air distribution pipes 2 . The bottom of the recovery chamber 21 is in the shape of an inverted cone, and the bottom end of the cone ...

Embodiment 2

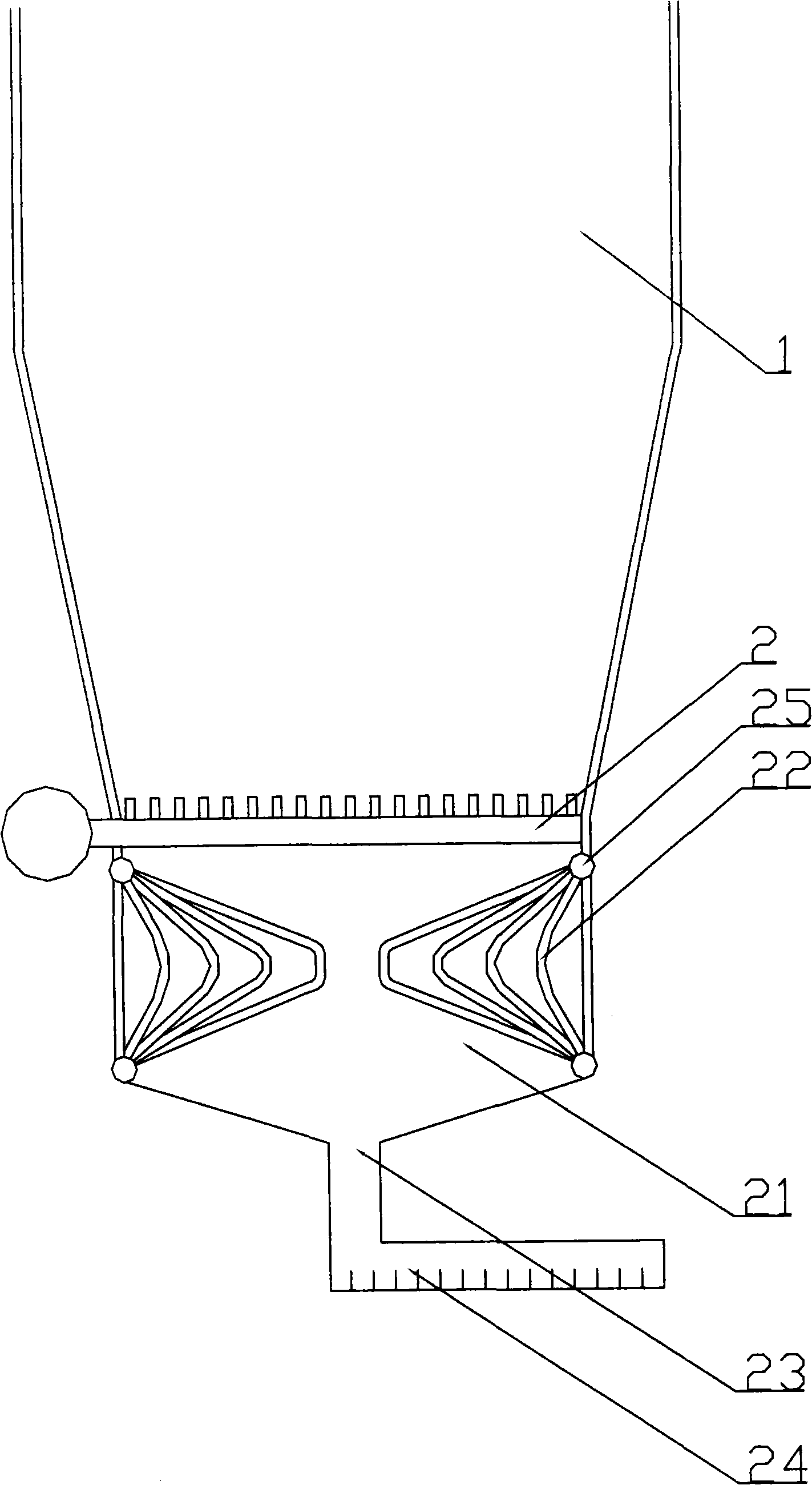

[0046] Such as figure 2 As shown, it is a structural schematic diagram of Embodiment 2 of a circulating fluidized bed boiler bottom slag heat recovery device of the present invention, wherein: the lower header 25 of the water-cooled wall. The main structure of embodiment 2 is the same as that of embodiment 1, but the heat exchange tube 22 on the cold slag heat exchange surface merges into the lower header 25 of the water-cooled wall of the furnace side wall, that is, the lower header 25 of the water-cooled wall of the furnace side wall is used as the middle The header makes the heat exchange tube on the cold slag heat exchange surface directly communicate with the water wall of the side wall of the furnace;

[0047] The bottom slag generated by combustion in the furnace 1 falls into the bottom slag heat recovery chamber 21 from the air distribution pipe 2, and directly contacts and exchanges heat with the cold slag heat exchange surface heat exchange tube 22 installed in the ...

Embodiment 3

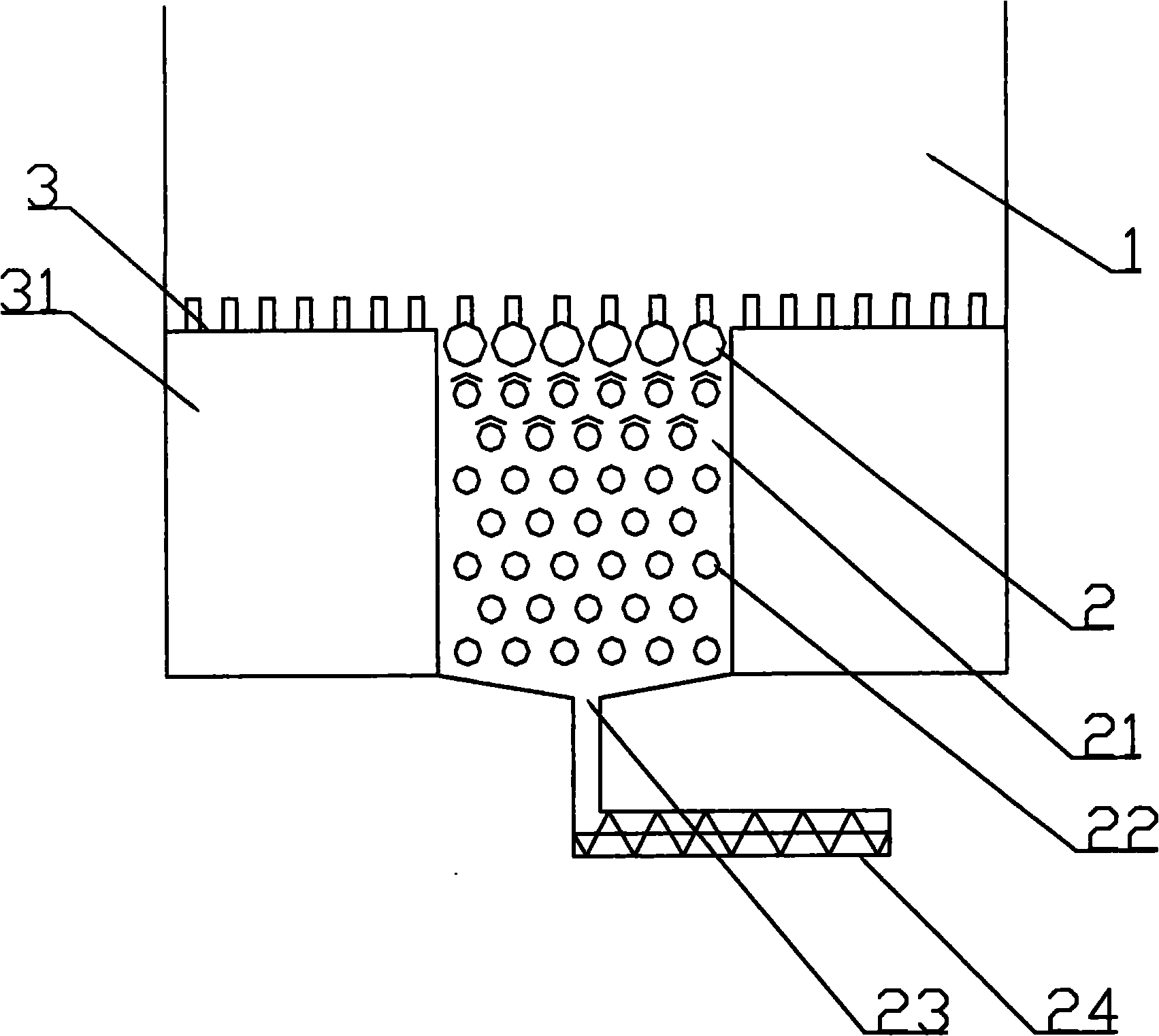

[0049] Such as image 3 As shown, it is a structural schematic diagram of Embodiment 3 of a circulating fluidized bed boiler bottom slag heat recovery device according to the present invention, in which: an air distribution plate 3 and an air chamber 31 . The main structure of embodiment 3 is the same as most of embodiment 1, the difference is:

[0050] The bottom bed surface of circulating fluidized bed boiler furnace 1 is divided into three areas along the width direction of the furnace: the air distribution device in the area near the left wall and the right wall is the air distribution plate 3, and the air distribution device in the middle area is the air distribution pipe 2. Bottom slag heat recovery chamber 21 is provided below the air distribution pipe 2, and there is a space between the two air distribution pipes to accommodate the passage of bottom slag particles. The recovery chamber 21 is directly connected to the boiler furnace 1 through the gap between the air di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com