Boiler furnace slag waste heat utilization system and process

A boiler slag and process technology, which is applied in the boiler slag waste heat utilization system and process field, can solve the problems of boiler room structural corrosion hazards, waste of water resources, environmental heat pollution, etc., to avoid energy loss and environmental pollution, and prevent oxygen levels from rising High, systematic and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

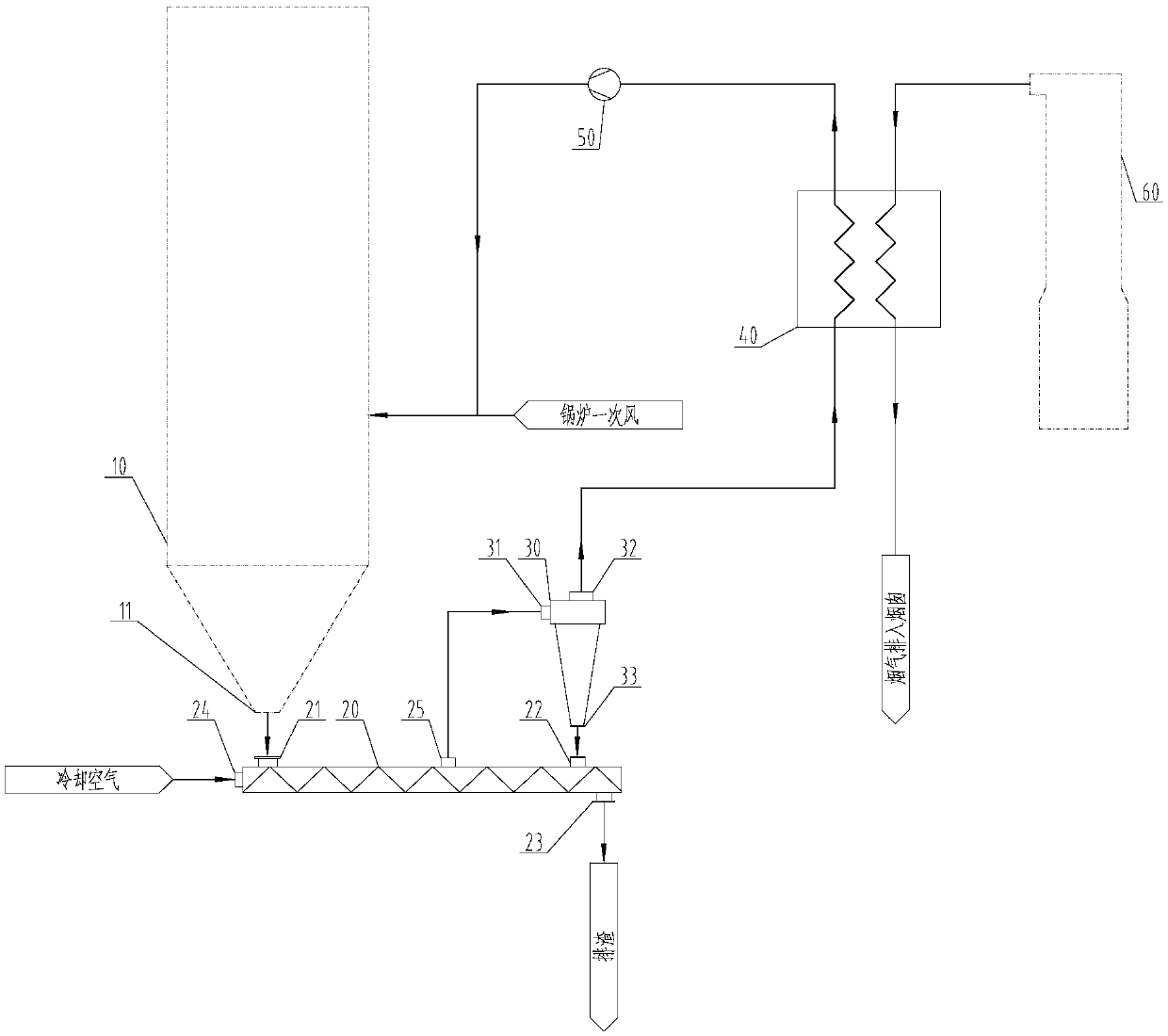

[0035] A boiler slag waste heat utilization system, such as figure 1 As shown, it includes a boiler 10 , a dry slag discharger 20 , a cyclone separator 30 , a heat exchanger 40 , an induced draft fan 50 , and a wet desulfurization tower 60 .

[0036] The slag produced by the combustion of the boiler 10 is discharged from the outlet 11 of the boiler slag hopper, and enters the dry slag discharger 20 from the first slag inlet 21 of the dry slag discharger 20 .

[0037] The principle of the dry slag discharger 20 is to pass air at normal temperature into the inside of the slag cooler, and through the heat exchange between the air and the slag inside the slag cooler, the heat of the slag is transferred to the air to achieve the purpose of cooling the slag, and at the same time, the heated slag is The air is exhausted from the slag cooler.

[0038] The slag after air cooling is discharged from 23 slag outlets.

[0039] As the heat exchange medium, air enters the dry slag discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com