Method for measuring capacity of alkalis boiler slag potassium contained in blast furnace using gas-slag balancing technique

A balanced and technical technology, applied in the field of physical and chemical testing, which can solve the problems of increasing the complexity and difficulty of high-temperature experiments of potassium capacity, and volatile alkali vapor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

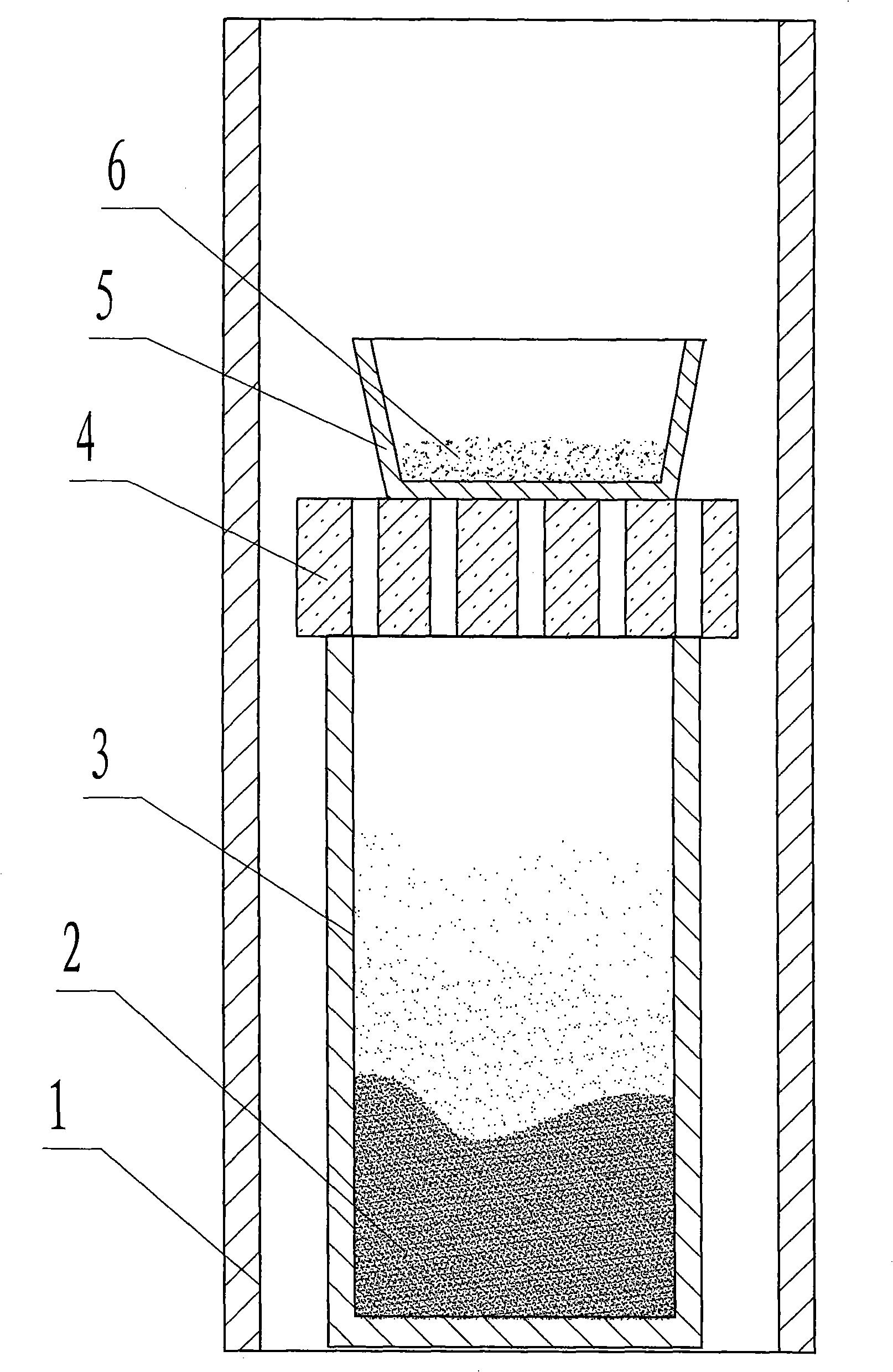

Method used

Image

Examples

Embodiment 2

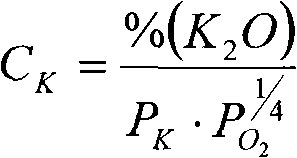

[0055] Example 2: CaO and SiO that have been calcined at 950°C for 13 hours 2 、Al 2 o 3 , MgO, ZnO, TiO 2 Oxides, according to the mass ratio of 42.1%, 39.62%, 9.22%, 8.44%, 0.02%, 0.6%, are mixed and put into a graphite crucible, mixed and melted at 1450°C, fully stirred, taken out, cooled, crushed and mixed evenly to form CaO-SiO 2 -Al 2 o 3 -MgO-ZnO-TiO 2 The slag sample is reserved. Weigh 55 grams of potassium carbonate reagent and put it into the corundum crucible at the lower part of the corundum tube. in a platinum crucible. Ar is introduced from the bottom of the corundum tube to remove the air in the corundum tube and then the temperature rises. When the furnace temperature rises to 1425°C, a certain composition of CO and CO after purification is introduced. 2 , Ar mixed gas, the flow ratio is 100ml / min: 100ml / min: 200ml / min, at a constant temperature of 1425°C and start timing, after 5 hours the equilibrium reaction is completed, and the chemical analysis sa...

Embodiment 3

[0056] Example 3: CaO and SiO that have been calcined at 1000°C for 12 hours 2 、Al 2 o 3 , MgO, ZnO, TiO 2 Oxide, according to the ratio of 33.3%, 40.5%, 13.11%, 12.36%, 0.03%, 0.7%, mixed and put into a graphite crucible, mixed and melted at 1400 ° C, fully stirred and taken out, cooled, crushed and mixed evenly to form CaO -SiO 2 -Al 2 o 3 -MgO-ZnO-TiO 2 The slag sample is reserved. Weigh 60 grams of potassium carbonate reagent and put it into the corundum crucible at the lower part of the corundum tube. in a platinum crucible. Ar is introduced from the bottom of the corundum tube to remove the air in the corundum tube and then the temperature rises. When the temperature of the furnace rises to 1450 ° C, a certain composition of CO and CO after purification is introduced. 2 , Ar mixed gas, the flow ratio is 100ml / min: 100ml / min: 200ml / min, at a constant temperature of 1450°C and start timing, after 4 hours, the equilibrium reaction is completed, and the chemical ana...

Embodiment 4

[0057] Example 4: CaO and SiO that have been calcined at 960°C for 13 hours 2 、Al 2 o 3 , MgO, ZnO, TiO 2 Oxides, according to the mass ratio of 42.1%, 27.7%, 14.28%, 15.0%, 0.02%, 0.9%, are mixed and put into a graphite crucible, mixed and melted at 1450°C, fully stirred, taken out, cooled, crushed and mixed evenly to form CaO-SiO 2 -Al 2 o 3 -MgO-ZnO-TiO 2 The slag sample is reserved. Weigh 55 grams of potassium carbonate reagent and put it into the corundum crucible at the lower part of the corundum tube. in a platinum crucible. Ar is introduced from the bottom of the corundum tube to remove the air in the corundum tube and then the temperature rises. When the furnace temperature rises to 1425°C, a certain composition of CO and CO after purification is introduced. 2 , Ar mixed gas, the flow ratio is 100ml / min: 100ml / min: 200ml / min, at a constant temperature of 1425°C and start timing, after 5 hours the equilibrium reaction is completed, and the chemical analysis sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com